Numberall Stamp & Tool

Metal Marking and Stamping Equipment

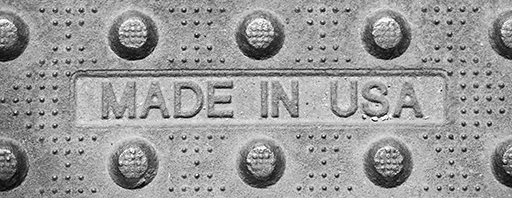

Numberall Stamp & Tool is a manufacturer of metal marking equipment for industry. We have been designing, manufacturing, and servicing a complete line of equipment since 1930. Our products utilize several marking methods including metal marking and hot stamping. These methods can be used for stamping serial numbers, date codes, product codes, and other permanent identification needs.

Industry Leader in Metal Stamping Tools

If you are new to metal marking and need assistance in determining the correct marking equipment for your needs, try using the Metal Marking Product Chooser or Metal Marking Product Matrix. The Product Chooser asks you a few quick questions to determine your marking needs, then recommends a product based on your answers. The Product Matrix displays a summarized comparison chart of all our products. For further assistance, please call one of our qualified sales representatives at 1-207-876-3541.

From the Numberall Blog:

Price Increase

Numberall is having a price increase effective February 14, 2022. We have held our pricing as long as possible, but due to the pandemic, the skyrocketing price increases in materials, some of which have quadrupled and other items beyond our control, we must adjust our...

Character Cleaning Picks

In the indent marking industry keeping characters clean helps prolong life. Buildup of material can cause characters to fail. Numberall offers character cleaning picks that can eliminate these problems. Each pick is made in the USA with USA chromium-vanadium 8650...

2022 Date Code

As we end 2021 (finally) we remind our customers that the dates codes need to be updated. It's time to check your supply of type, making sure you have enough 2's for the new date code. Checking that the custom dies are up to date with the proper year. Verifying that...