Roll Marking Presses

The Model 301 Hand-Operated or 301A Air-Operated presses are economical machines for light duty marking of round parts with an even depth of impression. Built for industrial applications, you can stamp characters up to a 1/4” in aluminum and 5/32″ characters in mild steel. Despite its compact bench-top size, this press is able to incorporate oversize endplates for larger diameter parts.

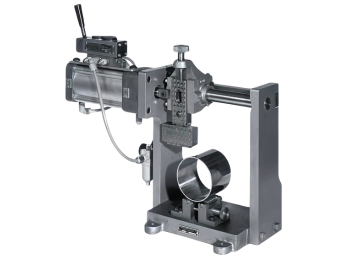

Model 301 Hand-Operated Roll Marking Press

Boost your marking efficiency with the Model 301. Place the round part in the adjustable fixture, pull the handle, and let the marking device (Numbering Heads, Type Holders, or Marking Dies) do the work. The part rotates smoothly as the code is stamped. Swap the part at the end of the stroke for continuous operation. Optimize your marking process with the reliable Model 301.

Model 301A Air-Operated Roll Marking Press

Optimize your marking process with the Model 301A Air-Operated presses. Our presses deliver even depth impressions up to 1/4” in aluminum and 5/32” in mild steel. The Model 301A can use an FRL unit to maintain clean, regulated air supply to the air cylinder, ensuring consistent force and uniform marking depth. This setup boosts efficiency, reduces maintenance, and extends the press’s lifespan.

Model 301 Custom Roll Marking Presses

Numberall’s Model 301 and 301A Roll Marking Presses feature customizable oversized endplates and custom fixtures, available in two sizes, increasing the maximum part diameter from 1-5/8″ to 5-7/8″. These presses ensure even depth impressions, stamping up to 1/4” characters in aluminum and 5/32” in mild steel. Despite their compact size, they offer enhanced functionality for industrial applications, making them ideal for tailored marking solutions.