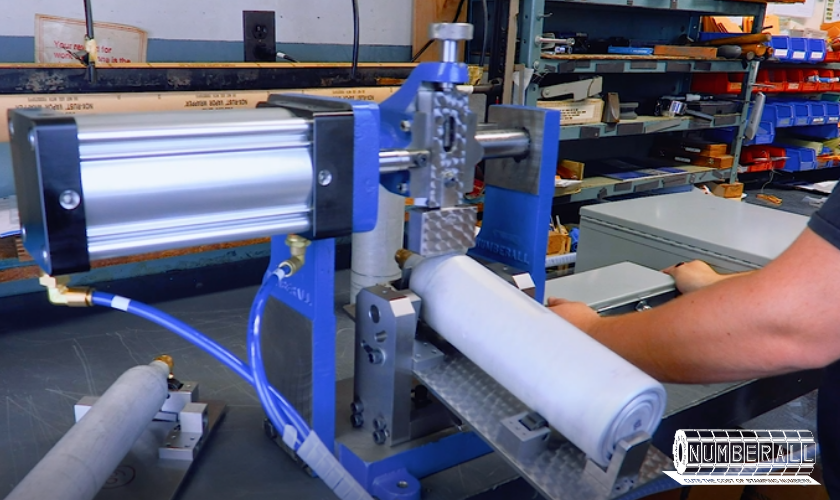

Roll Marking for the Steel Tank Cylinder Industry

Since 1930 Numberall has been developing exceptional metal marking equipment solutions for manufacturers of gas cylinders.

Durable Markings

Our equipment ensures long-lasting and legible markings that withstand harsh environments.

Customizable Solutions

We offer custom marking solutions to meet the specific needs of your industry.

Efficient Operation

Designed for automatic operation and offering consistent and accurate markings.

Gas Cylinder Traceability with Numberall Roll Marking and Numbering Machines

When it comes to industrial manufacturing, the traceability of gas cylinders is a crucial concern. Numberall provides a wide range of roll marking and numbering machines designed to meet the specific needs of manufacturers producing various types of steel gas cylinders (tanks). These machines offer a reliable solution for marking gas cylinders, ensuring long-lasting traceability and adherence to industry standards.

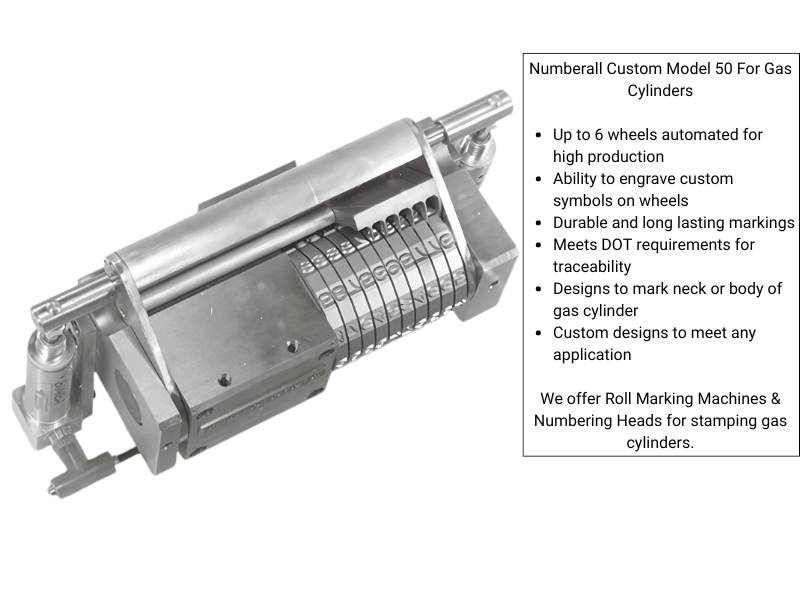

Customized Solutions for Gas Cylinder (Steel Tanks) Manufacturers

Numberall’s roll marking machines are known for their flexibility and precision. Whether it’s marking nameplates, tags, keys, small parts, or fully assembled parts, their equipment can handle diverse components. For manufacturers of steel gas cylinders, this means the ability to tailor marking solutions to their specific requirements. From high-pressure cylinders to low-pressure ones, Numberall’s machines can accurately mark each cylinder, ensuring clear and permanent identification.

Need a sample marking of your parts? We will be happy to mark your parts and provide a product solution, at no cost to you.

Request a Free Sample Marking of Your Parts

Advantages of Indenting with Metal Stamping Machines

One of the standout features of Numberall’s roll marking machines is the use of indenting with metal stamping. This technique creates an indentation on the cylinder’s surface, providing several advantages:

- Durability: Indented markings are permanent and withstand harsh conditions, ensuring legibility throughout the cylinder’s lifecycle.

- Precision: Metal stamping machines deliver high accuracy, guaranteeing consistent and precise markings.

- Cost-Effectiveness: The automated nature of these machines enhances efficiency and reduces costs, especially for large-scale production.

- Heat Resistance: Indenting does not expose the metal to heat, preventing any heat-related changes to the cylinder.

Integration with Modern Manufacturing Processes

Numberall’s marking equipment is designed for easy integration with modern manufacturing processes. Their systems can be seamlessly incorporated into production lines, ensuring minimal disruption and maximum efficiency. This integration capability is essential for maintaining high production speeds and ensuring that all parts are marked accurately and consistently.

Get in touch with us today to discuss your gas cylinder traceability needs. Our knowledgeable sales engineers can offer product solutions to fit your application.

Unmatched Benefits of Our Stamping Equipment

Customization

We offer tailored solutions to meet the unique marking requirements of your automotive parts.

Durability

Our stamping tools are designed to last, providing consistent performance even in demanding environments.

Precision

Ensure clear and accurate markings with our high-precision equipment.

Compliance

Meet industry standards and regulations with our reliable marking solutions.

Efficiency

Increase productivity with our easy-to-use and efficient stamping tools.

Support

Benefit from our exceptional customer service and technical support, ensuring your operations run smoothly.

Industry Standards for Gas Cylinders: How Numberall Delivers Excellence

In the manufacturing of gas cylinders, adherence to stringent regulations is crucial for ensuring safety and traceability. The Department of Transportation (DOT) has established comprehensive guidelines for marking and identifying gas cylinders, which manufacturers must follow to maintain compliance and safety.

Essential Identification Marks

Markings on gas cylinders are essential for tracking and ensuring safety. These marks provide vital information about a cylinder’s origin, ownership, and maintenance history. The key identification marks include:

- DOT or ICC Identification Number: This number signifies the cylinder’s compliance with DOT regulations. For example, “DOT3BB3500” denotes a specific type of cylinder.

- Serial Number: Each cylinder is assigned a unique number for identification.

- Owner Information: Markings include the names of both the original and current owners, usually located on the neck ring.

- Maintenance Dates: Dates for the original hydrostatic test and any subsequent maintenance or requalification tests must be included.

Benefits of Indenting Gas Cylinders with Metal Stamping

Numberall’s roll marking machines utilize the indenting technique, creating durable markings that withstand harsh conditions. Here’s why indenting with metal stamping is advantageous:

- Long-Lasting: Indented markings are permanent, ensuring legibility throughout the cylinder’s lifespan.

- Accuracy: High precision in metal stamping guarantees consistent and exact markings.

- Efficiency: Automated stamping is cost-effective, particularly for large-scale production.

- No Heat Exposure: Indenting does not involve heat, preventing any changes to the cylinder’s structure.

Numberall’s roll marking and numbering machines are essential for manufacturers needing reliable and compliant marking solutions for gas cylinders. By adhering to DOT regulations and utilizing advanced indenting techniques, Numberall ensures long-lasting traceability and compliance, setting the standard in the industry.

Looking for a solution to marking your gas cylinder products?

Discover how our metal marking equipment can streamline your gas cylinder marking processes, enhance traceability, and ensure compliance with industry standards. Contact us today to learn more about customized solutions tailored to your specific needs.