June 1, 2025Marking Devices, Metal Marking

A Look at Numberall’s High-Quality Metal Marking Machines

The Unyielding Foundation: Why Numberall's Metal Marking Machines Are Built to Last for Decades

At Numberall, we believe that the true measure of a metal marking machine isn’t just its immediate performance, but its enduring quality, precision, and longevity. This core philosophy drives our unwavering commitment to using premium, USA-sourced raw materials in the construction of every piece of Numberall equipment.

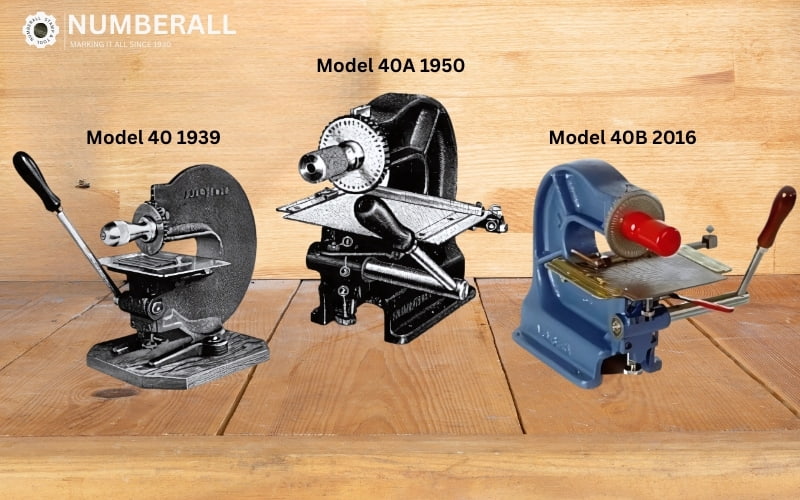

This isn’t merely a point of pride; it’s a fundamental promise that translates directly into the superior durability and consistent performance our customers rely on. In fact, it’s why many of our products are still operating reliably after 40 years in the field.

We often discuss the exceptional quality embedded within Numberall machines, but it’s important to delve deeper into what our equipment is made of and why our material choices make our high-quality metal marking machines industry leaders in toughness and reliability across our entire product line.

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Recent Posts

The Numberall Difference: Engineering Excellence from the Ground Up for All Our Products

Our dedication to robust construction and material integrity extends to every Numberall product, from individual components to complete marking systems.

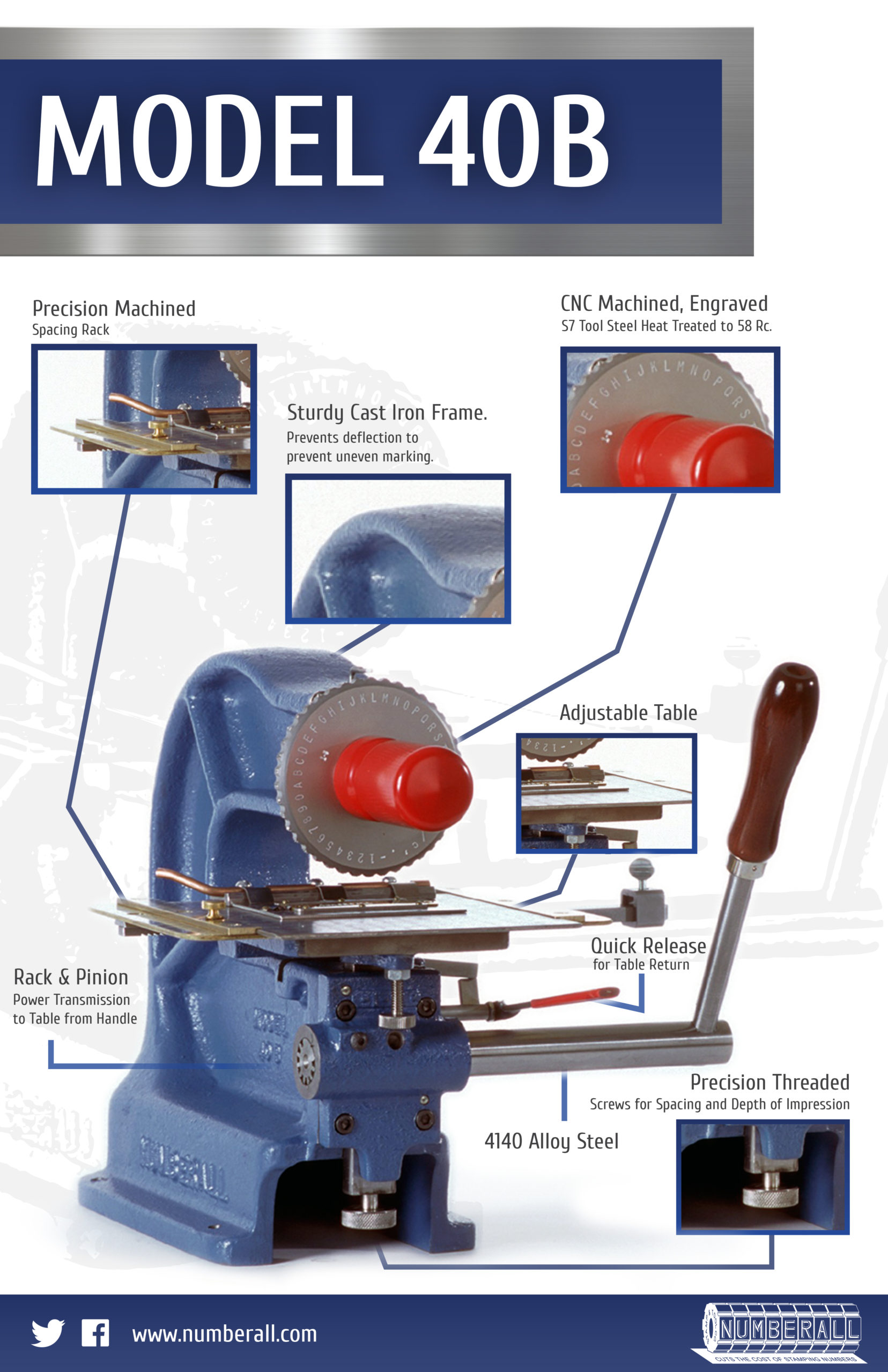

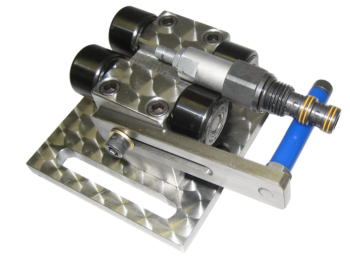

Let’s take our best-selling Model 40B metal marking machine as a prime example of our material philosophy in action. The moment you engage with a Model 40B, you’ll notice its substantial, reassuring weight. This isn’t incidental; it’s a direct result of our dedication to robust construction.

The Unyielding Core: Heavy-Duty Cast Iron Frames

- A significant portion of the Model 40B’s impressive weight comes from its sturdy, heavy-duty cast iron “C” frame.

- Sourced from a trusted Maine foundry company right here in the USA, this high-grade cast iron is chosen specifically for its exceptional rigidity.

- This prevents any deflection during the marking process, guaranteeing consistently even and precise impressions every single time.

- It’s a foundational element that ensures maximum stability and eliminates the common issues of uneven marking often found in lesser machines. This commitment to robust frames extends to our entire line of presses, designed for stability and consistent depth.

Precision and Endurance: American Tool Steel Components Across All Marking Equipment

- Beyond the robust frames, the critical working components of all Numberall machines – including numbering heads, type holders, and individual type characters – are meticulously crafted from high-grade American tool steel.

- This steel undergoes precision heat treatment for severe usage and an exceptionally long life. To ensure the integrity and origin of every batch, we require a certificate of quality and origin from our steel suppliers.

- This rigorous vetting process eliminates the complexities and inconsistencies associated with lower-quality, imported materials, allowing us to maintain our exacting standards and deliver truly superior products.

In the Model 40B and our versatile numbering heads, this premium American steel is found in vital components such as:

- The adjustable tables, ensuring stable and repeatable part positioning.

- Precision threaded screws for exact spacing and consistent depth of impression.

Ergonomic handles, designed for comfortable and efficient operation. - Precision machined spacing racks, enabling accurate character advancement.

- Numbering dials and wheels, which are high-precision CNC engraved S7 tool steel that’s heat-treated to a formidable 58 on the Rockwell scale.

- This specific treatment enhances wear resistance and ensures crisp, clear character impressions over countless operations, making our numbering heads ideal for serial numbering, part identification, and date coding where clarity and durability are paramount.

Engineered for Smooth Operation and Durability

- Our commitment to quality extends to every detail. The Model 40B incorporates a quick release mechanism for table return and a robust rack and pinion power transmission from the handle to the table.

- This rack and pinion system, often found in high-quality applications like vehicle steering mechanisms, speaks volumes about the attention to detail and durability built into our machines.

- It provides smooth, consistent, and powerful movement, contributing to the machine’s overall reliability and operator comfort.

- Similarly, our type holders are engineered for secure type retention and optimal impression transfer, while our presses are designed for powerful, repeatable force application.

Numberall Products Excel Across Diverse Applications

The inherent quality of Numberall equipment makes it the preferred choice for demanding applications across various industries. Our products excel in:

- Automotive: Vin numbering, component marking, part traceability.

- Aviation: High-precision marking on critical components, compliance coding.

- Defense & Firearms: Serializing firearms, marking military equipment with extreme durability.

- Manufacturing: Part identification, batch coding, branding on diverse metal surfaces.

- Tool & Die: Marking tools, dies, and fixtures with permanent, clear identification.

- Energy & Oil/Gas: Marking pipes, valves, and components in harsh environments.

- General Industrial: Any application requiring permanent, legible marking on metal parts, from small tags to large castings.

Whether you need a standalone press, a versatile numbering head, robust type holders, or durable steel type, Numberall delivers tools that perform reliably decade after decade.

did you know?

no-cost marking of your sample part with expert recommendations

The Numberall Promise: Long-Term Value and Unwavering Performance

Our unwavering commitment to American raw materials isn’t just about manufacturing; it’s about delivering a tangible benefit to your operations. When you invest in Numberall metal marking equipment, you’re not just buying a machine; you’re acquiring a durable, precise, and reliable asset designed to perform consistently for decades. This means:

- Reduced Downtime: Machines built with superior materials are less prone to breakdowns and require less frequent maintenance, thanks to components designed for longevity.

- Consistent Quality: High-grade components and precision manufacturing ensure uniform impressions and reliable performance day after day, year after year.

- Exceptional Longevity: Your Numberall machine is an investment that will continue to pay dividends through its extended operational life, often exceeding 40 years of active service, far outlasting equipment made with compromise.

- Choosing Numberall means choosing equipment forged from the best materials, for the best performance, and a legacy of reliability.

Interested in the Model 40B or Our Full Range of Metal Marking Solutions?

Ready to experience the unmatched durability and precision of an American-made Numberall metal marking machine, numbering head, or press?

Contact us today to learn more about the Model 40B or any of our other robust marking solutions, and let us demonstrate the lasting value of true quality and performance.

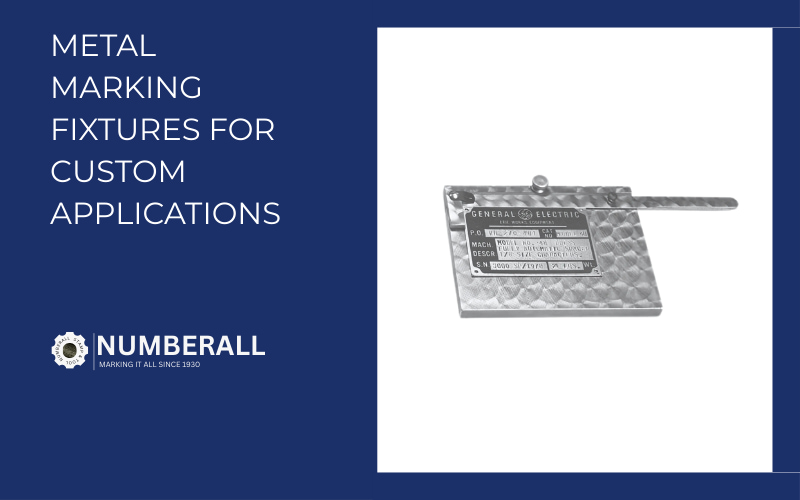

Looking for an economical custom solution to marking your equipment?

Discover custom metal marking solutions for your equipment. With our long history of innovation since 1930, we can meet any requirement. Making it easy to do business with us. Request a Quote today!

Recent Posts

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.