by Daniel Bayerdorffer | Feb 7, 2022 | Blog

February 7, 2022

Numberall is having a price increase effective February 14, 2022.

We have held our pricing as long as possible, but due to the pandemic, the skyrocketing price increases in materials, some of which have quadrupled and other items beyond our control, we must adjust our pricing.

We will honor our quotes until March 14, 2022. If you need additional time, please contact the sales office.

It has been a very trying couple of years. We are still maintaining our work force and are on a standard 40 hour work week, 5 days a week. Sales office is open 8:00am to 4:30pm EST. We have been extremely successful at maintaining our quick deliveries. However, we are at the mercy of our suppliers. Any changes in the supply chain can and will effect us.

If you would like just an updated price list, please contact us. We can email or fax it.

Thank you for your past, current and future support.

by Daniel Bayerdorffer | Dec 14, 2021 | Blog

As we end 2021 (finally) we remind our customers that the dates codes need to be updated.

It’s time to check your supply of type, making sure you have enough 2’s for the new date code. Checking that

the custom dies are up to date with the proper year. Verifying that the numbering head doesn’t have

any damaged characters or need special engraved wheels.

We offer many marking options, including:

- Date code, shift codes, etc. in a solid block – If you need multi-character stamps to speed up the change-over of codes, we can provide stamps that will work for you. Our multi-character stamps are perfect for codes that remain the same, such as the year 2021 or even a section of a part code.

- Standard steel type pieces – These pieces are compatible with Numberall’s Model 23 Type Holder, or your own type holder, for a uniformly spaced and aligned character sequence. Our standard steel type is engraved and precision heat treated on quality American steel, plus we manufacture blanks to high standards for accuracy, strength, and alignment.

- Numbering head wheels – We can special engrave numbering head wheels with the same character or groups of characters so that if a character gets worn or damaged, you can switch to the next one that works.

- Custom marking equipment – If none of the above methods work for your date marking, please reach out to us! We are happy to provide a quote for custom solutions to meet your needs.

Stock items will be shipped the next business day. Custom items could be 2-3 weeks. Shipping delays

are common this time of year.

Thank you for your past business, looking forward for a prosperous 2022 for all of us!

As always, MADE IN USA!

by Daniel Bayerdorffer | Aug 4, 2021 | Blog

Meet Mike Scott and wish him a happy retirement. After 38 years, Mike is retiring. If you have purchased a Model 40B, Model 23 Type Holder or any other press, Mike did the machining and most of the assembly. His function was to run and organize the press department. Making sure the other machinists were working on the proper parts to keep our quick deliveries. All presses, platforms, type holders, and the special fixtures was his responsibility. Keeping stock of all the inventory was another function. Giving purchasing lists of items such as nuts & bolts to casting, was under his control. If sales could not help solve a problem with the machine, you may have talked to Mike, to get your machine up and running.

Mike liked rebuilding the machines that he built.. My favorite saying to him was, here’s another one that was needs your help. It’s only 25 years old, couldn’t you have made it a little better? He’d respond I’ll fix it to last another 25 years!

His work ability was tremendous. Always making sure that product was 100% (or more). Working with engineering, suggesting changes or procedures to make and produce the best product. Mike always stepped up, when we needed parts made or assemble a machine in a rush. Especially when making modifications to allow customers parts to fit. Thanks Mike, it is appreciated!

We wish Mike and his wife the best in their retirement. We’re sure he’ll stop in to make sure we are doing it properly!!

by Daniel Bayerdorffer | Jul 7, 2021 | Blog, Numbering Heads

Numberall can make non-automatic large character marking heads .Most applications are for our Model 50P or Model 250P for serial numbering. However, some applications require manual wheel advancement. Shown is a Model 270P with 5 wheels 3/4″ characters with a space for 4 inserts. Each wheel has a random sequence, customized just for this application. The space for 4 inserts is also used with a large logo. To rotate the wheels, a tool is inserted into the holes on the edges of the wheels. By moving the tool, you rotate each wheel to the desired sequence.. For this application the Model 270P is mounted into a hot stamp press with foil. The foil allows the impression to be colored. This custom head was designed and built in 7 weeks. As always MADE IN USA!

by Daniel Bayerdorffer | Jan 25, 2021 | Blog

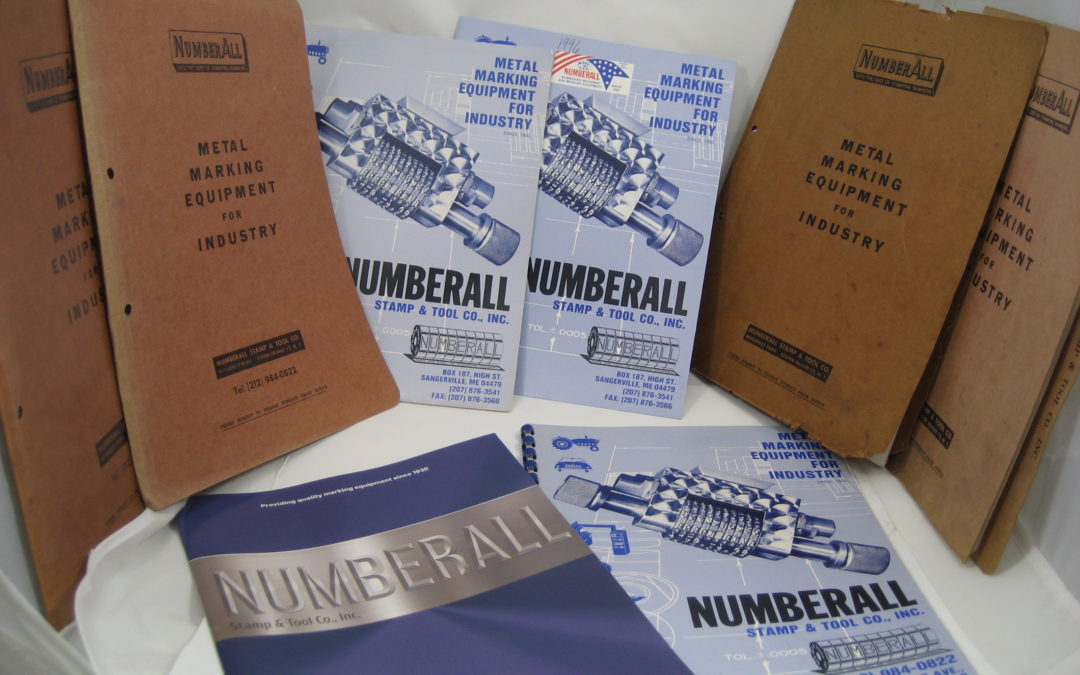

As we prepare the office for the new year, it‘s always interesting to reflect on past years. Looking through an old file drawer, we noticed the many changes thru the years in the catalogs. (more…)

by Numberall | Dec 3, 2020 | Blog, Hand Stamps, Type & Type Holders

With the first year of the new decade coming to a close, we have much to be thankful for here at Numberall. We were able to help many new and repeat customers in 2020, meet their metal marking needs, and fulfill various custom orders, including this Model 50P we modified to solve a customer’s clearance issue. Like many, we are excited to see what 2021 has in store. (more…)