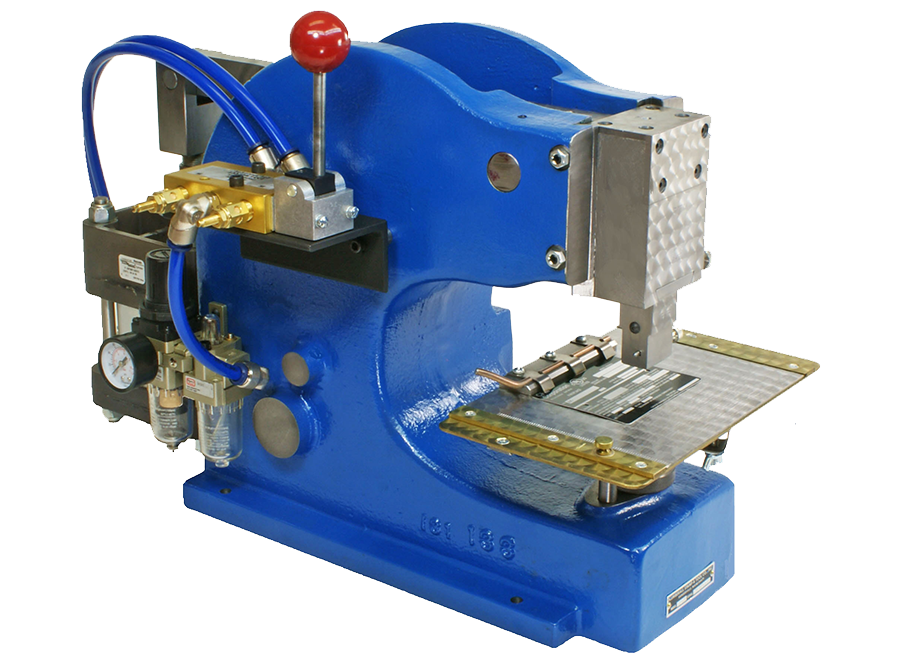

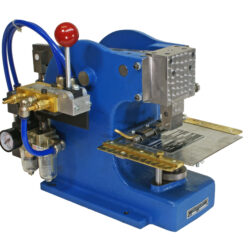

Model 131A Heavy Duty Air-Operated Bench Top Press

Numberall’s bench top presses save floor space and keep larger presses free. The Model 131A allows for adjustable stamping of various part thicknesses without height adjustments. Simply adjust the air pressure for precise stamping depth, perfect for marking name plates and flat objects. Experience the efficiency of Numberall’s air-operated presses today!

- Durable Construction

- Lifetime Support

- Custom Options Available

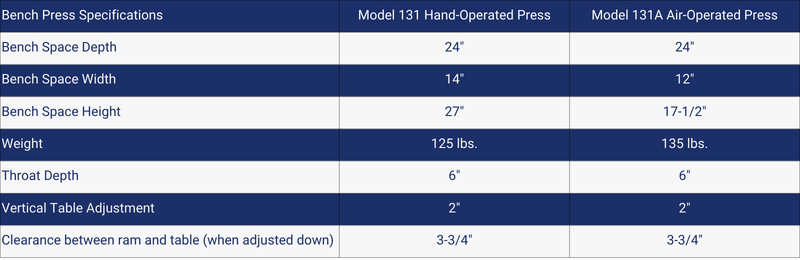

| Weight | 135 lbs |

|---|---|

| Dimensions | 24 × 12 × 17.5 in |

| Optional Equipment | Tripping Attachment (for use with the Model 50P only) |

Call For Quote

Quote Requirements

- Part Material (Steel, Aluminum, etc)

- Part Thickness

- Number of Characters to Stamp

- Character Size (inches)

- Access to Air or Electricity

Prefer to email a quote request?

Product Resources

Catalog Request

Product Manual (PDF)

Length of Impression Ruler (PDF)

Operation

The Model 131 is hand-operated. By manually pulling the lever, a cam is rotated to create the stamping force. The table would be adjusted so that when the cam rotates to high cam position, minimal effort is required to mark the part.

The Model 131A uses an air-cylinder to generate its power. A hand-operated lever valve is pulled toward the operator. This causes the ram to move down to stamp the part. Once stamped, the lever valve is released and the ram then moves to the home position. The Model 131A is a very simple, low maintenance press with few moving parts. In fact, we do not recommend any spare parts for this machine.

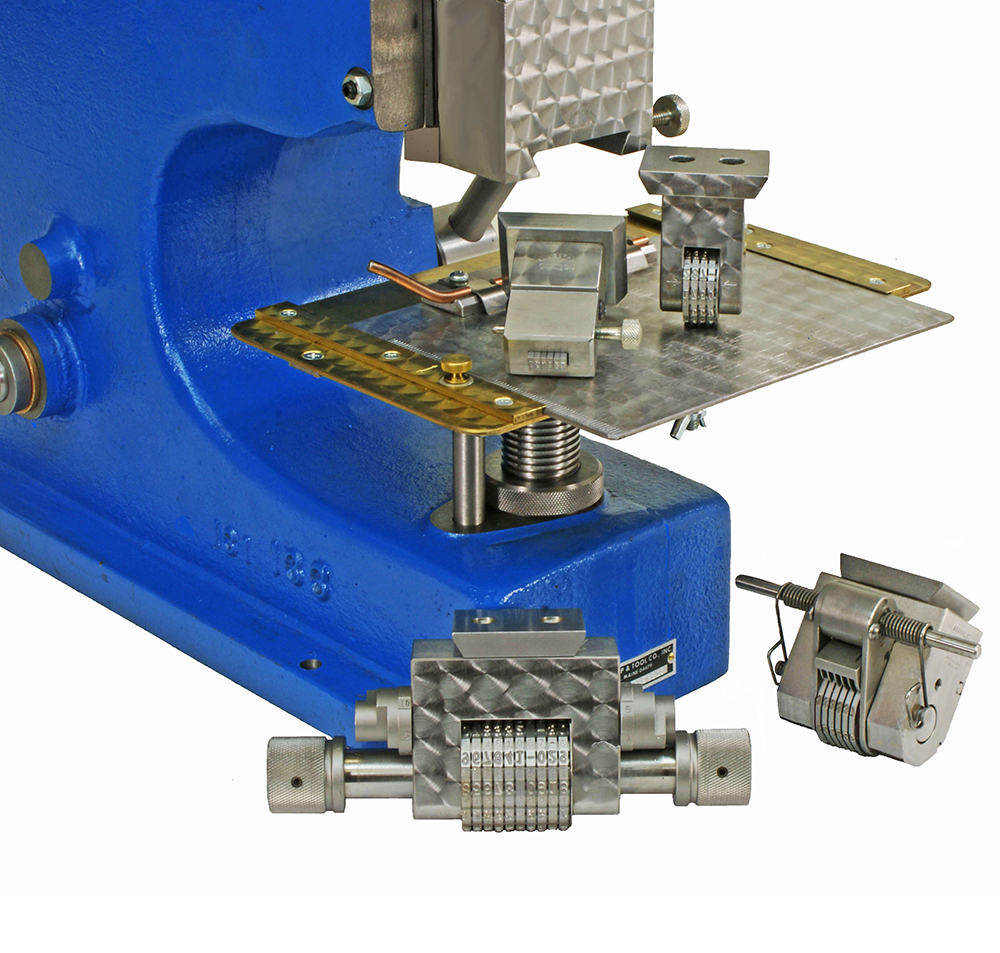

The Model 131A can be adjusted so that any part thickness within the stroke range can be stamped without height adjustment. By simply adjusting the air pressure, the press will stamp to a certain depth. Essentially the press will “stall out,” but not damage the part or press components because the air pressure is lower than standard. An acme screw and nut below the cast table regulate depth of stamping. A separate guiding rod helps align the table. By turning the acme nut you can raise or lower the table for depth adjustment.

The presses feature a short, safe 3/16” stroke, negating the need for external guarding. The Model 131A can be equipped with an optional two-hand trip. Numberall’s standard dovetail shank allows for quick changing of marking devices. The same dovetail is used in all of our presses as well as the Model 116 Dovetail Adapter.

Construction & Parts

The Models 131, 131A and 133 all use the same base casting. Numberall's presses have cast iron "C" frames for distortion-free stamping with a smooth, static non-impact marking force. No die cast parts are used. Many imported presses are made using round column construction with a spring release marking force, which may result in a harsh impact shock. The large quick-change dovetail ram evenly distributes the marking force across the marking device frame with minimal stress. Clearances and pressures are the same for all models.

Compatibility

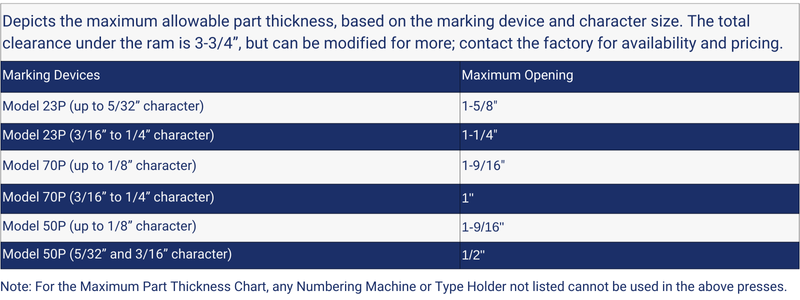

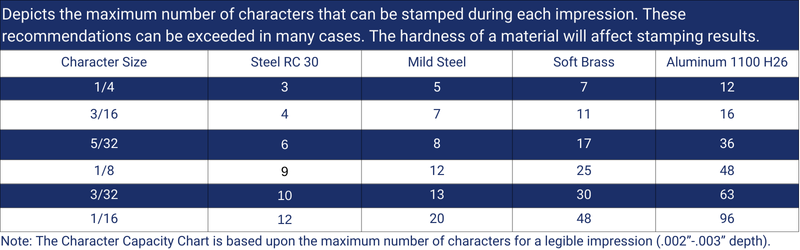

A variety of marking devices can be installed in the presses, depending on part thickness and character capacity requirements.

Maximum Part Thickness Chart

Character Capacity Chart

Options

- Tripping Attachment (for use with the Model 50P only)

- Adjustable Table (for in-out and left-right movement of table)

- Filter, Lubricator, Regulator, & Gauge (FLR&G) (for Model 131A only)

- Model 113 Strip Holder

- Universal Key Nest

- Custom Nest

Product Specs

Additional information

| Weight | 135 lbs |

|---|---|

| Dimensions | 24 × 12 × 17.5 in |

| Optional Equipment | Tripping Attachment (for use with the Model 50P only) |