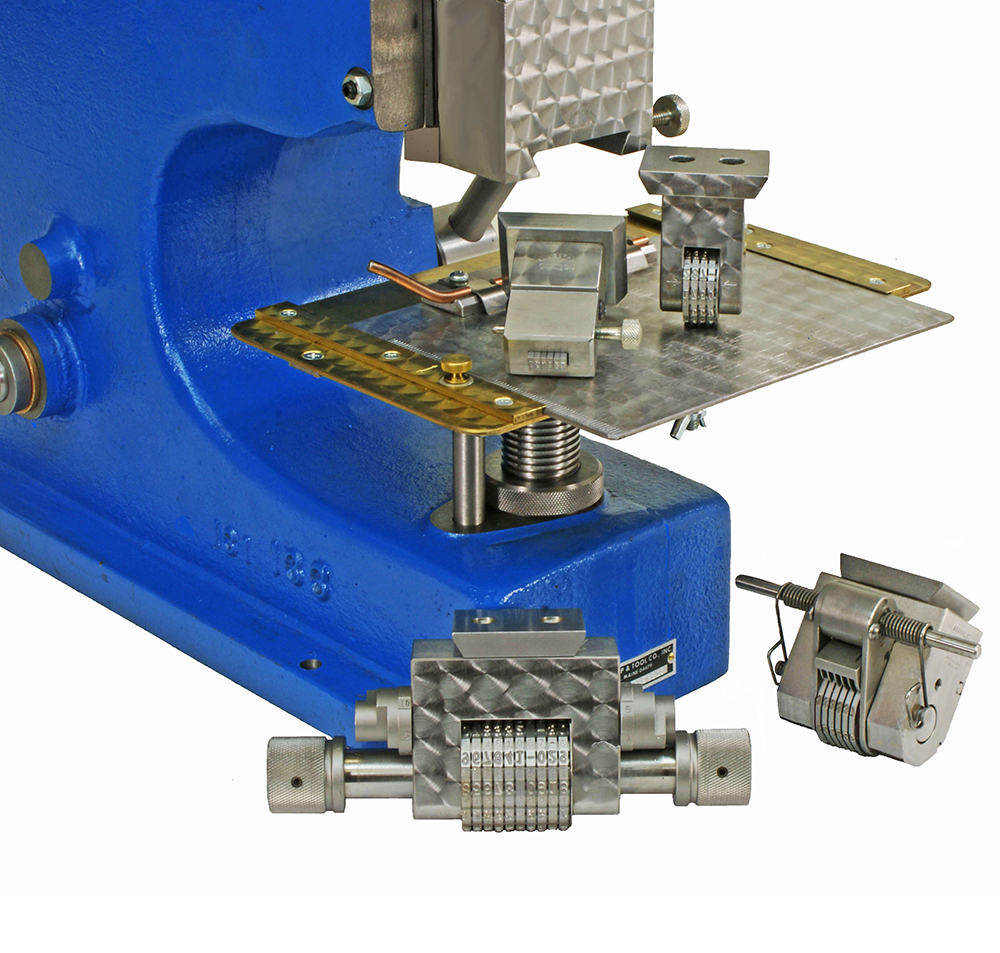

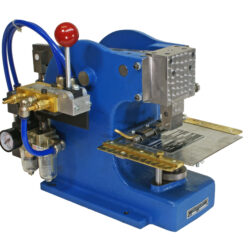

Model 133 Heavy Duty 1/2 HP Motorized Bench Top Press

Optimize your workspace with Numberall’s compact bench-top presses, designed to save floor space and efficiently mark name plates and flat objects. The heavy-duty Model 133 stands out with its 1/2 horsepower electric motor, requiring only 120 volts AC. Its reliable clutch and cam mechanism ensures simple operation and long-lasting performance, making it an ideal choice for your marking needs.

- Durable Construction

- Lifetime Support

- Custom Options Available

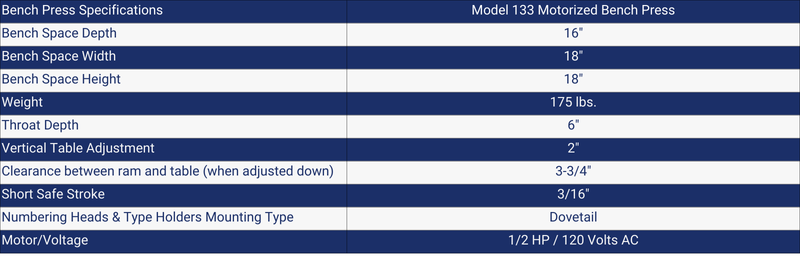

| Weight | 175 lbs |

|---|---|

| Dimensions | 16 × 18 × 18 in |

| Optional Equipment | Tripping Attachment (for use with the Model 50P only) |

Call For Quote

Quote Requirements

- Part Material (Steel, Aluminum, etc)

- Part Thickness

- Number of Characters to Stamp

- Character Size (inches)

- Access to Air or Electricity

Prefer to email a quote request?

Product Resources

Catalog Request

Product Manual (PDF)

Length of Impression Ruler (PDF)

Operation

- The Model 133 is a motorized press. It requires 120 volts AC electricity, so it can be used anywhere there is an outlet.

- It utilizes a 1/2 horsepower electric motor to drive a worm gear reducer. The clutch and cam mechanism is a design that has been proven effective through many years of service. Its operation is simple.

- The operator moves the operating lever down and the press cycles. With the standard Single Stroke Control, the press will only cycle once until the lever is released and actuated again.

- Motorized operation reduces operator's fatigue.

- An acme screw and nut, attached below the cast table, regulate depth of stamping. A separate guiding rod helps align the table. By turning the acme nut you can raise or lower the table for depth adjustment.

- The presses feature a short, safe 3/16” stroke, negating the need for external guarding. Numberall’s standard dovetail shank allows quick changing of marking devices.

- The same dovetail is used in all of our presses as well as the Model 116 Dovetail Adapter.

Construction & Parts

- The Models 131, 131A and 133 use the same base casting.

- Numberall's presses are husky, cast iron "C" frames for distortion-free stamping with a smooth, static non-impact marking force. No die cast parts are used.

- Many imported presses are made using round column construction with a spring release marking force, which may result in a harsh impact shock.

- The large quick-change dovetail ram evenly distributes the marking force across the marking device frame, with minimal part and marking device stress.

- Clearances and pressures are the same for each model.

Compatibility

A variety of marking devices can be installed in the presses, depending on part thickness and character capacity requirements.

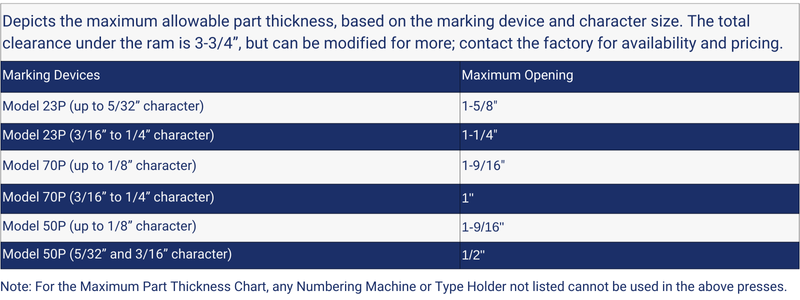

Maximum Part Thickness Chart

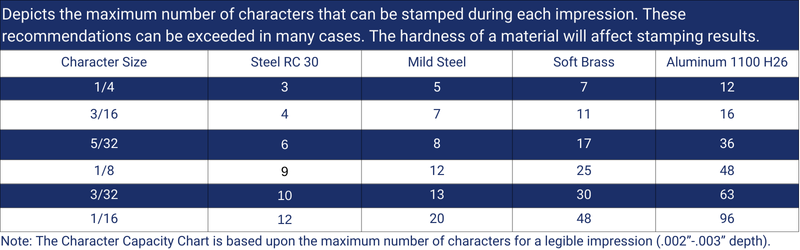

Character Capacity Chart

Options

- Tripping Attachment (for use with the Model 50P only)

- Adjustable Table (for in-out and left-right movement of table)

- Filter, Lubricator, Regulator, & Gauge (FLR&G) (for Model 131A only)

- Model 113 Strip Holder

- Universal Key Nest

- Custom Nest

Product Specifications

Additional information

| Weight | 175 lbs |

|---|---|

| Dimensions | 16 × 18 × 18 in |

| Optional Equipment | Tripping Attachment (for use with the Model 50P only) |