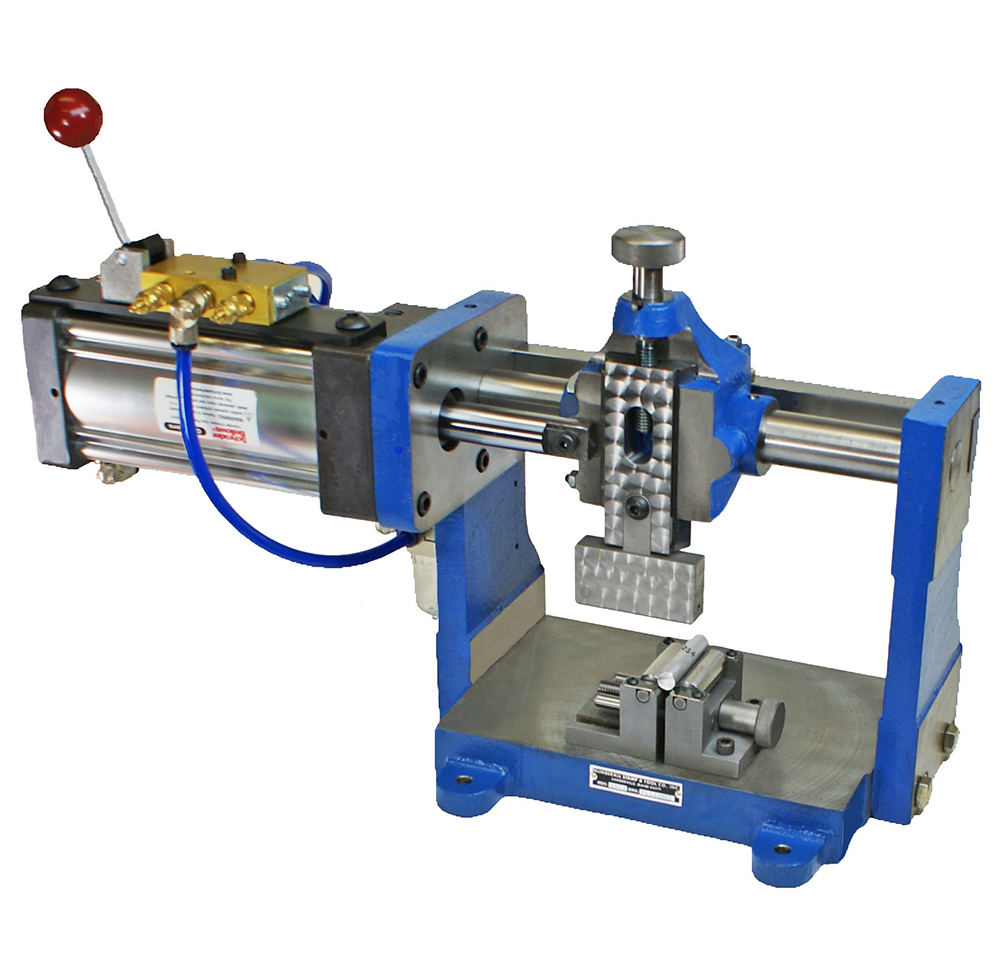

Model 301A Air-Operated Roll Marking Press

The Model 301A Air-Operated presses are ideal machines for light duty, economical marking of round parts with an even depth of impression. Built for industrial applications, you can stamp characters up to a 1/4” in aluminum and 5/32″ characters in mild steel. Despite its compact bench-top size, it is able to incorporate oversized endplates for larger diameter parts.

- Durable Construction

- Lifetime Support

- Custom Options Available

| Weight | 55 lbs |

|---|---|

| Dimensions | 25 × 20 × 30 in |

| Compatibility | Model 23P Type Holder (with multiple lines, if required) ** |

| Options | FRL & Gauge |

Call For Quote

Quote Requirements

- Part Material (Steel, Aluminum, etc)

- Part Thickness

- Number of Characters to Stamp

- Character Size (inches)

- Access to Air or Electricity

Prefer to email a quote request?

Product Resources

Catalog Request

Product Manual (PDF)

Length of Impression Ruler (PDF)

Operation

The Model 301A uses an air cylinder for power and includes a control valve. It is better suited for high production applications. Once the round part is placed in the adjustable holding fixture, the operator simply actuates the air valve and the cylinder extends the marking device part.

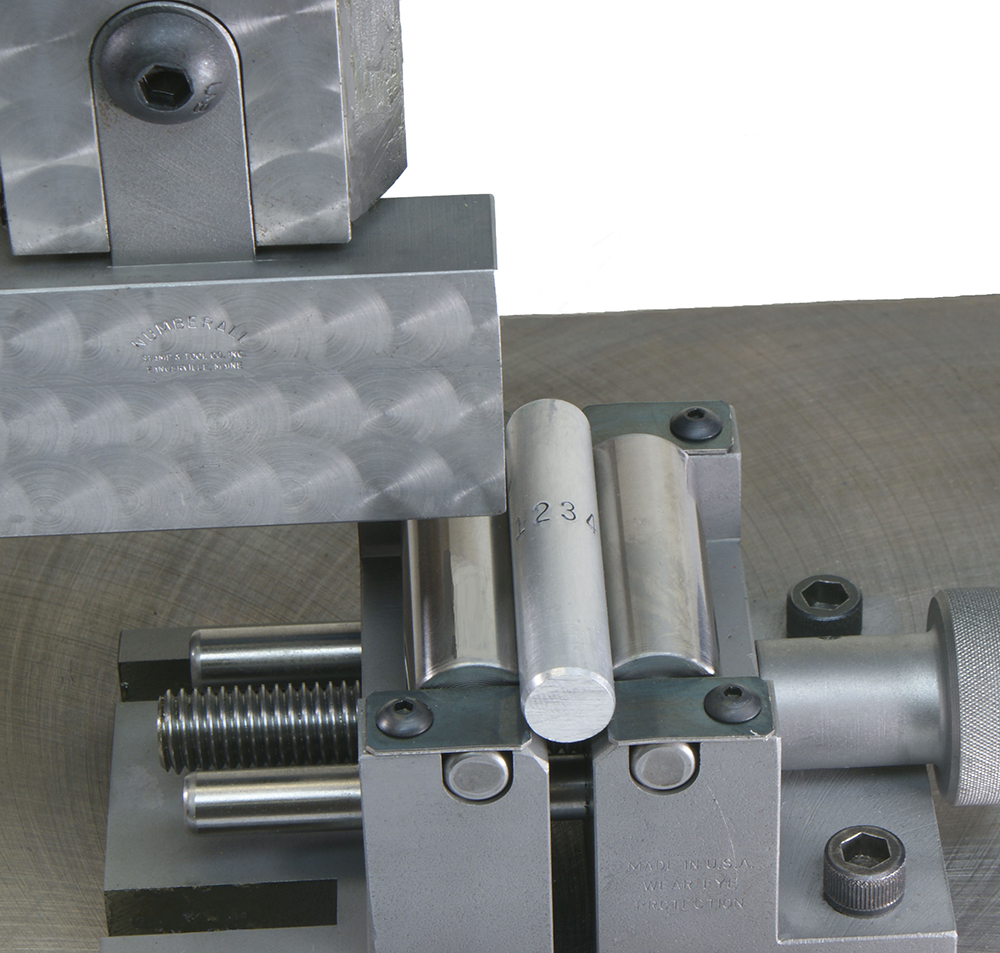

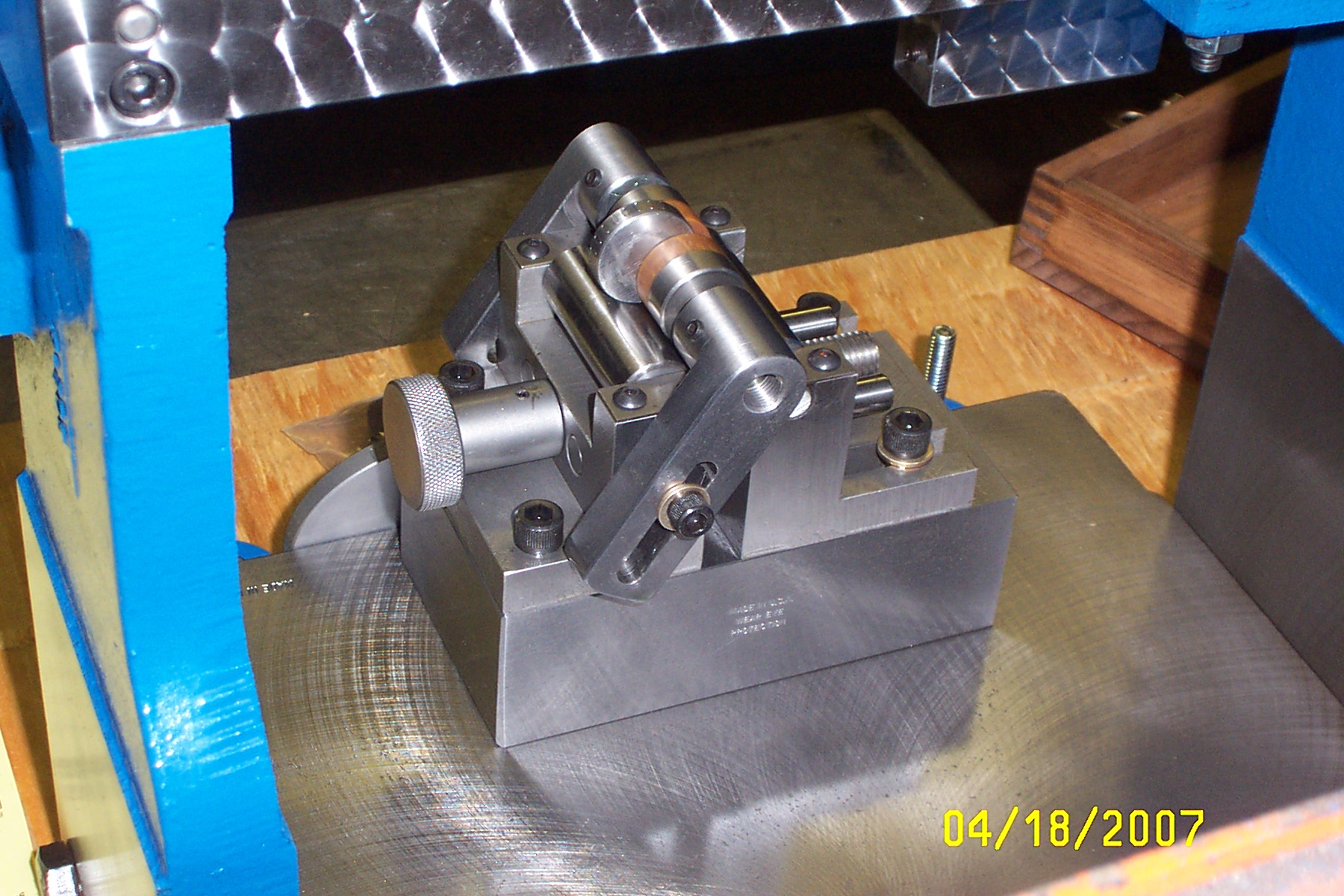

The marking device (one of our Numbering Heads, Type Holders, or Marking Dies) is pulled across the part. The part rotates in the fixture as the code is stamped around the part, all in one motion. At the end of the stroke, the cylinder stops. Remove the part, place another part in the fixture, reverse the air valve and the marking device is actuated in the opposite direction. An optional two-hand trip is available, instead of our standard valve.

An adjustment knob on the sliding head dovetail provides positive depth adjustment. A special rectangular shank is required to adapt the marking device to the sliding head. When setting up, place a part in the fixture, move the sliding head over the part. Turn the adjustment knob until the marking device touches the part. Move the sliding head to one side and turn the adjustment knob 1/4 of a turn. Mark a part and check for stamping depth. Move the adjustment knob in or out for proper stamping depth. Brass gibs on the dovetail and sliding head can be adjusted for wear and can tilt the marking device to correct for any part taper.

Compatibility

Numberall's Marking Devices that are compatible* with the Model 301:

- Model 23P Type Holder (with multiple lines, if required)**

- Model 70P Non-Automatic Numbering Head

- Model 50P Automatic Numbering Head

- Special Dies

Generally, with a Model 23P Type Holder and our standard adjustable holding fixture, you can mark parts from 3/8” to 1-5/8” diameter. We offer oversize endplates for more clearance by requesting the Oversize Roll Marking Machine. The first oversize endplates will give an additional 2-1/8” of clearance. Meanwhile, the second will give an additional 4-1/4” of clearance.

*Compatibility is based on character size, number of lines and type of material.

**It is best to obtain sample stampings for multiple line applications.

Options

- Lubricator, Filter, Regulator, & Gauge

- Two-Hand Tripping Attachment

- Adjustable Holding Fixture

- 1st and 2nd Oversize Endplates

- Custom Fixtures*

*Numberall has designed fixtures to stamp the edges of coins and medallions without marring the surfaces. We also have fixtures with interchangeable arbors for stamping hollow parts or rings. For parts with varying part diameters or stepped parts, our standard adjustable holding fixture rollers can be modified to hold the part securely when marking.

Additional information

| Weight | 55 lbs |

|---|---|

| Dimensions | 25 × 20 × 30 in |

| Compatibility | Model 23P Type Holder (with multiple lines, if required) ** |

| Options | FRL & Gauge |