Model 60 Hand-Held Numbering Head

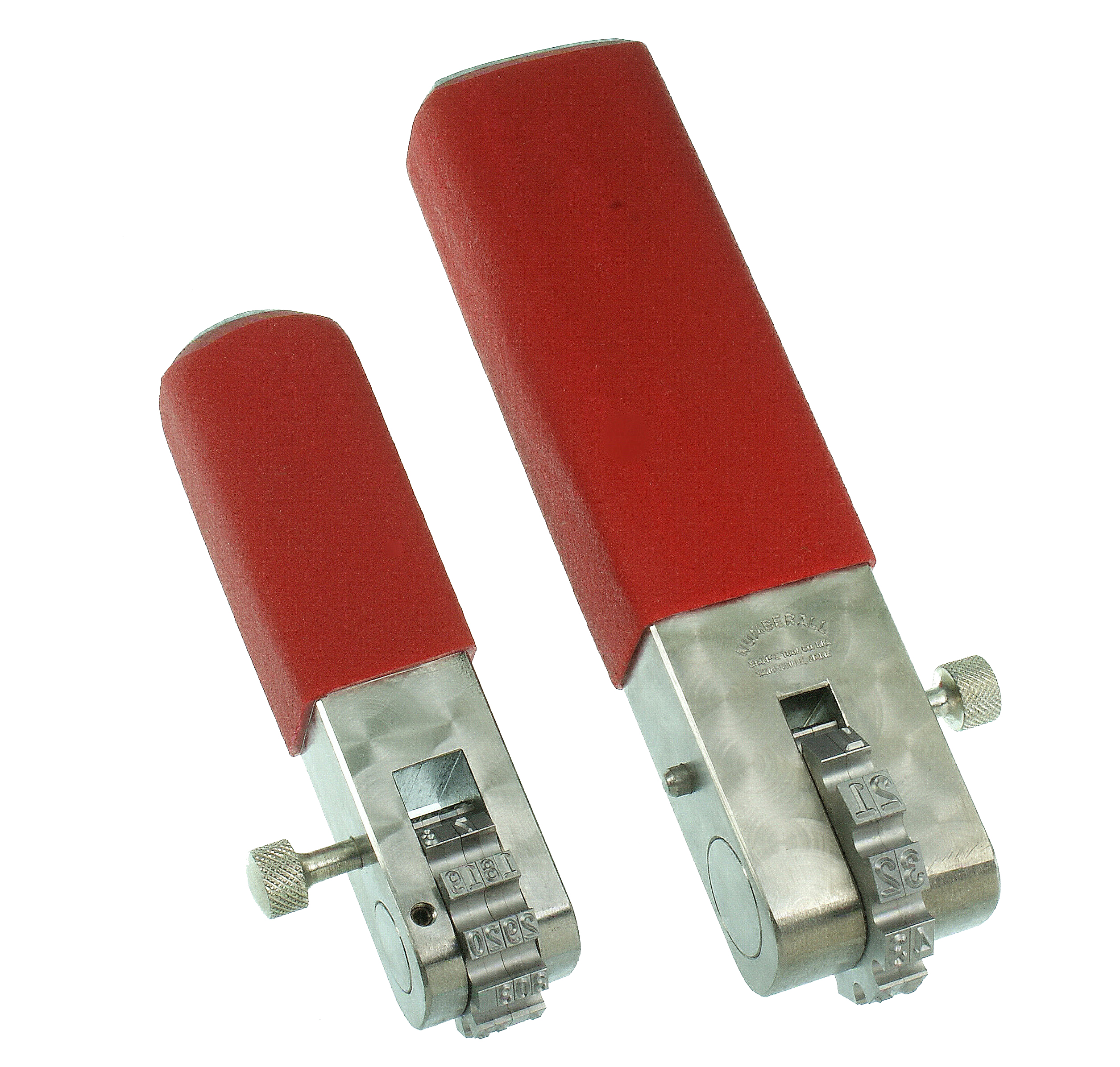

The Model 60 offers simplified construction and low cost while delivering performance and durability. Light and compact, yet durable, the Model 60 is ideal for marking products like keys, nameplates, and parts constructed of mild steel or similar materials.

- Durable Construction

- Lifetime Support

- Custom Options Available

| Weight | 6 lbs |

|---|---|

| Dimensions | 10 × 8 × 8 in |

| Character Size | 1/16", 3/32", 1/8", 5/32", 3/16" |

| Number of Wheels | 2, 3, 4, 5 |

Price range: $744.00 through $1,819.00

Need a custom quote?

Product Resources

Catalog Request

Product Manual (PDF)

Length of Impression Ruler (PDF)

Operation

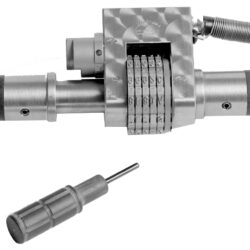

- To set a desired character sequence remove the pin to free all the wheels. Push the pin back into the frame until it touches the first wheel. Then, set the first wheel to the desired character and push the pin through first wheel to lock it in place. Repeat this same action for all wheels until the proper character sequence is obtained. Push the lock pin completely through the other side of the frame until properly seated. The pin may be inserted into the frame from either direction. With a little practice, any character sequence can be set quickly and easily.

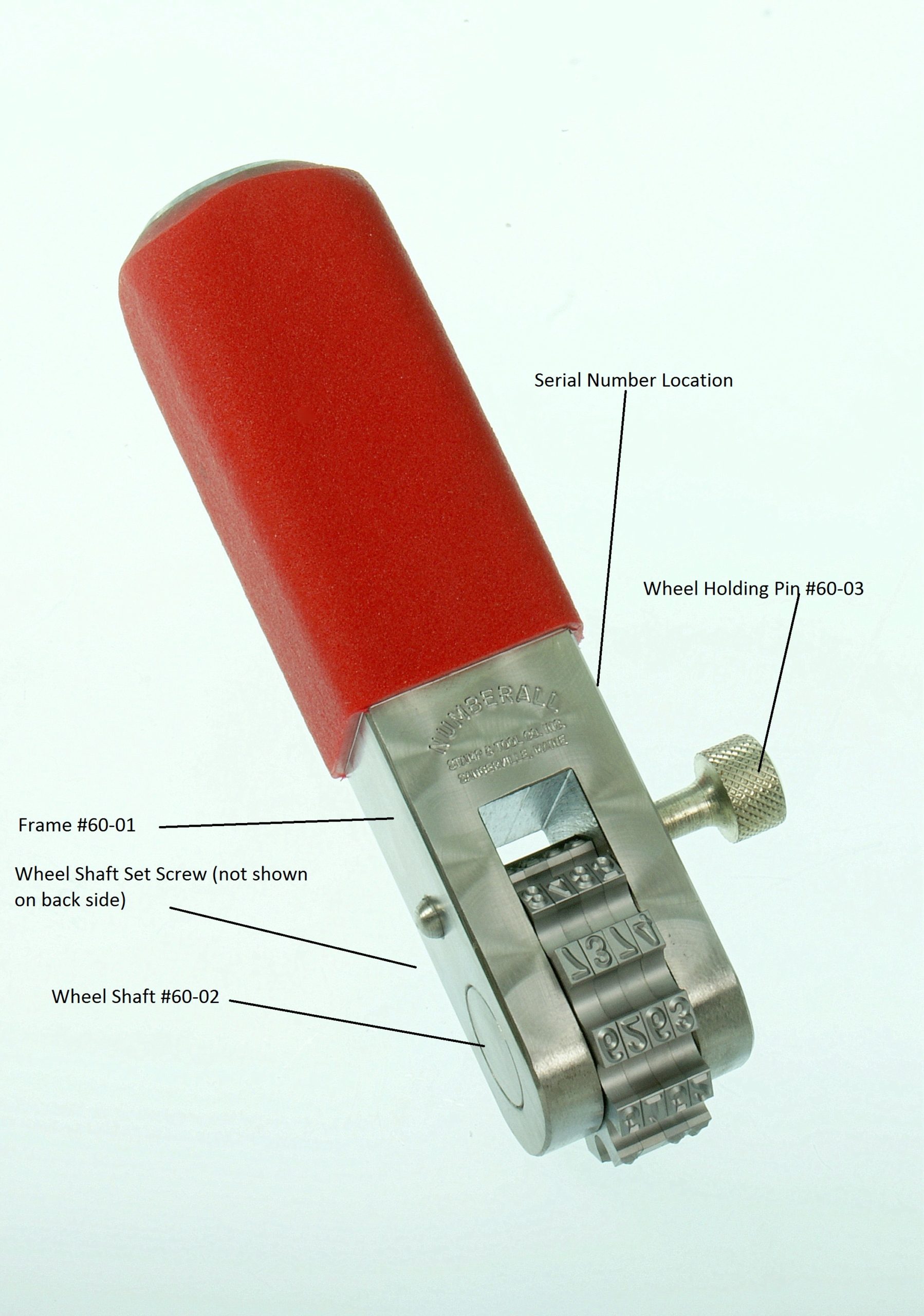

Construction and Parts

- The Model 60 is equipped with a vinyl-coated hand shank that absorbs vibration and shock occurring during the marking operation when the shank is struck with a hammer.

- A single tapered locking pin thrust through the frame and in the notches of the wheels, holds the wheels in alignment.

- The wheels are meticulously engraved for accuracy, strength, and alignment. Made of high-grade alloy tool steel, the wheels are precision heat-treated for severe usage.

- The hand shanks are constructed of high-grade, heat-treated alloy steel and resist chipping and mushrooming.

Options

- Press-style shanks are also available. Please contact us for pricing and availability.

Product Specs

| Characters on Standard Wheels* (11 division) | |

| Letters | A B C D E F G H I J K and blank, I omitted |

| Letters | L M N O P Q R S T U V and blank, O omitted |

| Figures | 1 2 3 4 5 6 7 8 9 0 and blank |

| Available Character Sizes | |

| 1/16", 3/32", 1/8", 5/32", 3/16" | |

| Number of Wheels* | |

| 2 to 5 |

*Note: Wheels can be engraved with any character, symbols, or styles. Contact factory for pricing and availability.

Consult our Length of Impression Gauge, included with our catalog, to determine character size required and associated Length of Impression.

Additional information

| Weight | 6 lbs |

|---|---|

| Dimensions | 10 × 8 × 8 in |

| Character Size | 1/16", 3/32", 1/8", 5/32", 3/16" |

| Number of Wheels | 2, 3, 4, 5 |