Manual & Semi-Automatic Numbering Heads

Numberall’s Manual Indexing and Semi-Automatic Numbering Heads offer an economical option for indenting and stamping parts with precision. Explore our versatile range designed for dependable part marking and product numbering, including the popular hand-held Model 60 Numbering Head and Models 70, 80, 85, and 83, which provide flexibility with both hand-held and press shank options. Manufactured with the highest quality materials for exceptional durability, these heads are engineered for rapid, accurate, and consistent numbering, delivering precise marks for reliable part marking and lasting value. Choose Numberall for dependable manual and semi-automatic numbering heads built for performance.

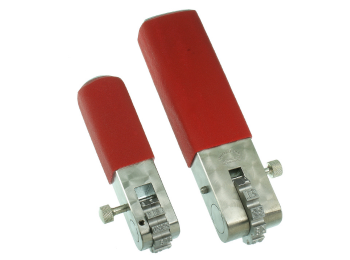

Model 60 Hand-Held Numbering Head

The Model 60 offers simplified construction and low cost while delivering performance and durability. Light and compact, yet durable, Model 60 is ideal for marking products like keys, nameplates, and parts constructed of mild steel or similar materials.

Model 70H Hand-Held Numbering Head

The Model 70 is used to stamp repetitive sequences with consistently uniform character alignment and depth of impression. It has a one-piece frame and shank of heat-treated alloy steel. Adaptable and versatile, there is virtually no limit to the range of products that can be marked.

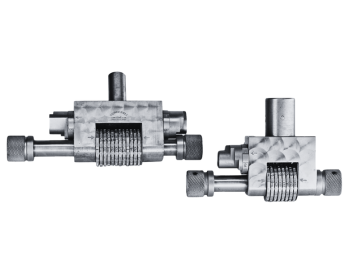

Model 70P Press-Shank Numbering Head

The Model 70P is equipped with a standard press shank for use with most hand or power presses. It maintains a one piece frame and shank made of heat-treated alloy steel. Adaptable and versatile, this press is ideal for stamping repetitive sequences with consistently uniform character alignment and impression depth.

Model 73H Heavy Duty Hand-Held Numbering Head

The Model 73H Heavy Duty is similar in construction and function to the Model 70, but is made specifically for heavy duty marking. By utilizing large diameter wheels and frames, the Model 73HD enables the operator to use more force without causing machine deflection.

Model 73P Press Shank Heavy Duty Numbering Head

The Model 73P Heavy Duty utilizes large diameter wheels and frames, enables the operator to use more force without causing machine deflection. Best used when marking requires large character sizes, multiple character wheels and applications that require severe usage or high forces.

Model 80H 1 Wheel Quick-Change Hand-Held Numbering Head

The Model 80H differs from the Model 70 by offering a one wheel quick-change feature that is ideal for lowvolume consecutive numbering. The quick-change feature enables the operator to quickly change the last character in the character sequence.

Model 80P 1 Wheel Quick-Change Press-Shank Numbering Head

The innovative design of the Model 80P Press-Shank guarantees consistently uniform character alignment and depth of impression. Multiple wheels are held in position by retaining pawls and retaining pawls springs. A retaining pawl seats the index plate on each of the one-piece wheels

Model 85H 2 Wheel Quick-Change Hand-Held Numbering Head

The Model 85 is similar to the Model 80, but offers a 2-wheel quick-change feature. The expanded quick change feature of the last two wheels enables the operator to quickly change the last two characters in the marking sequence.

Model 85P 2 Wheel Quick-Change Press Shank Numbering Head

The Model 85P Press-Shank offers quick selection by sliding the wheel shaft to the left and rotating the knobs. By sliding the wheel shaft to the right and rotating the knobs, the unit’s wheel is quickly set. Both quick-change wheels are indexed for direct sight reading, thus simplifying the selection of the correct characters.

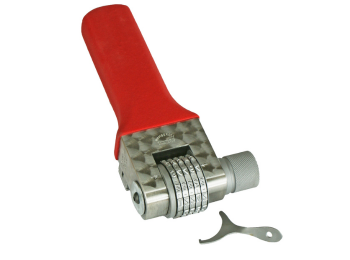

Model 83H Quick-Change Wheels Hand-Held Numbering Head

The Model 83H Hand-Held is ideal for the marking of identification numbers and letters. Its quick-change wheels offer the fastest setup possible for semi-automatic identification marking equipment. Of course, its features are best put to use when the character sequence requires frequent, random changes.

Model 83P Quick-Change Wheels Press-Shank Numbering Head

The Model 83P Press-Shank operates by rotating the selector knobs to the desired wheel number, sliding the wheel shaft to contact the selector knob, and then turning the knurled knobs to rotate the wheel shaft, the proper characters are selected for the marking sequence. All wheels are indexed for direct sight reading