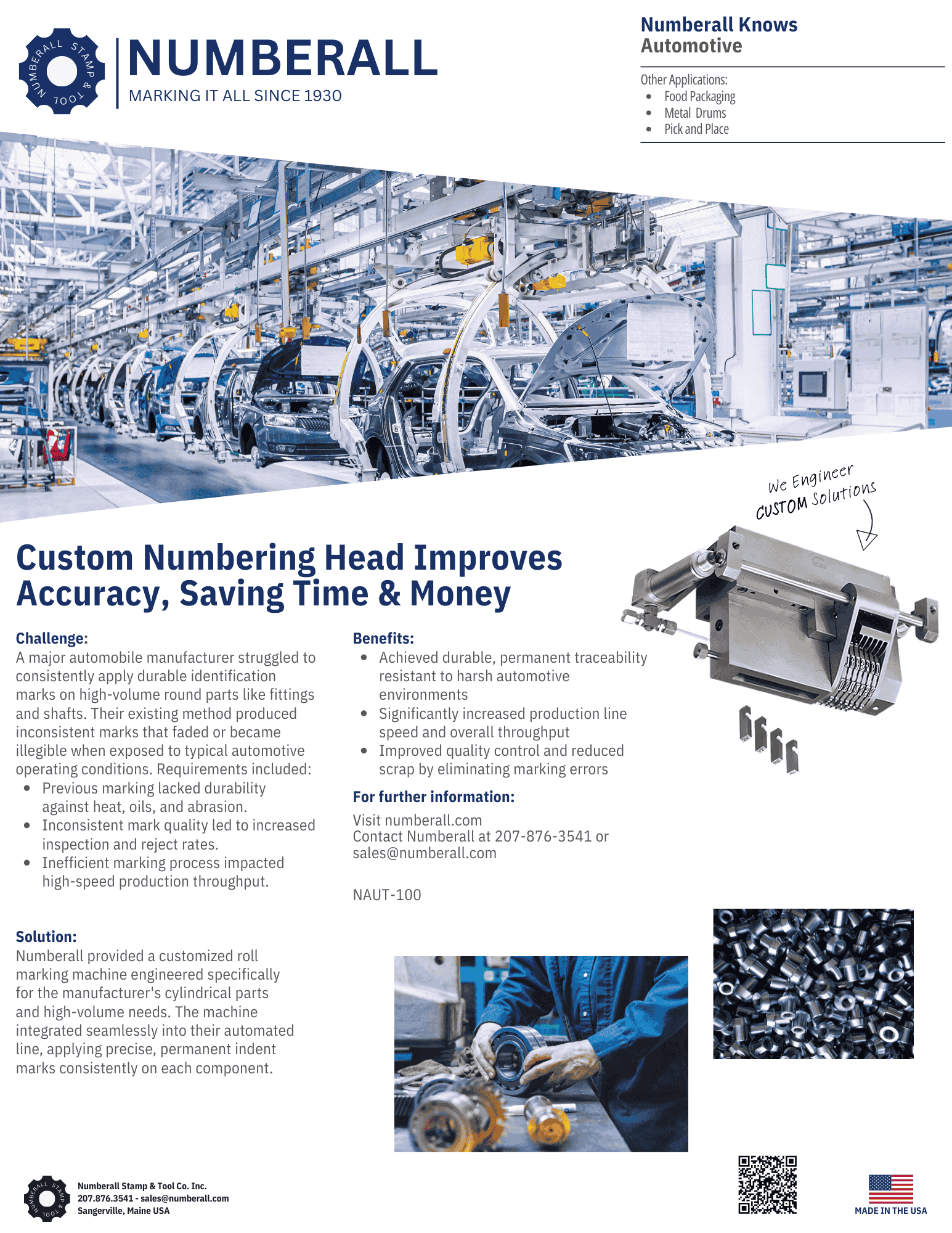

Metal Marking for the Automotive Industry

Trusted since 1930 for American-made metal marking: The leader in marking Automotive & OEM Parts

Durable Markings

Our equipment ensures long-lasting and legible markings that withstand harsh environments.

Customizable Solutions

We offer custom marking solutions to meet the specific needs of your industry.

Efficient Operation

Designed for automatic operation and offering consistent and accurate markings.

Driving Quality and Compliance: Numberall Metal Marking for the Automotive Industry

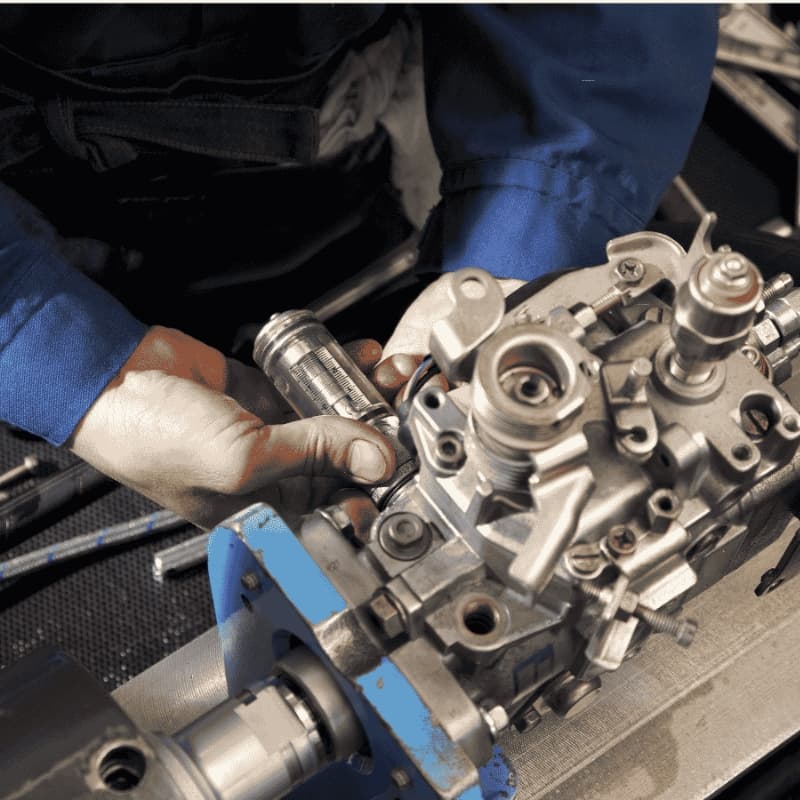

We know traceability in automotive manufacturing industry. The ability to definitively identify and trace every component is not just a best practice – it’s a cornerstone of quality assurance, regulatory adherence, and streamlined supply chain management. Numberall metal marking equipment provides a robust and reliable solution, indelibly marking automotive parts with precise information that endures the entire lifecycle of the vehicle.

Numberall has been a trusted name in the automotive industry for nearly a century. Working with OEMs and automotive manufacturers, developing solutions to their unique applications. Our products are designed to meet the rigorous demands of automotive parts regulations, ensuring that our markings remain clear and legible beyond the life of the part.

Numberall Knows: Marking Automotive Parts

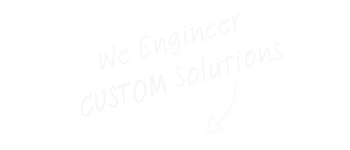

A customer with automotive components needed a solution to longevity of part identification in harsh environments.

The Foundational Importance of Direct Part Marking in Automotive Manufacturing

The automotive industry operates under intense scrutiny, with stringent demands for safety, reliability, and accountability. Permanent part marking, facilitated by Numberall’s advanced equipment, is essential for achieving these critical objectives:

- Regulatory Compliance: Automotive manufacturers must adhere to a complex web of international and local regulations concerning component identification for safety standards, emissions tracking, and recall procedures. Durable, tamper-proof markings ensure compliance and mitigate potential legal and financial risks.

- Quality Control and Assurance: Precise part marking enables granular tracking throughout the manufacturing process, allowing for the identification of defective components early on, preventing their integration into final assemblies and minimizing costly rework.

- Efficient Recall Management: In the event of a recall, clear and permanent markings are crucial for quickly and accurately identifying affected vehicles and components, ensuring swift and effective remediation, and safeguarding consumer trust.

- Supply Chain Visibility: Unique part identification facilitates seamless tracking across the complex automotive supply chain, from raw material sourcing to final assembly and aftermarket service. This enhanced visibility improves inventory management, reduces counterfeiting, and optimizes logistics.

- Combating Counterfeit Parts: Permanent, difficult-to-remove markings act as a deterrent against counterfeit parts, protecting brand integrity and ensuring the safety and reliability of vehicles.

- Lifecycle Management: From production to recycling, permanent markings provide a consistent data carrier, enabling efficient tracking of component history and material composition.

Unlike temporary marking methods that can degrade or be removed during harsh manufacturing processes or vehicle operation, Numberall’s metal indentation technology creates a permanent mark that withstands abrasion, chemicals, high temperatures, and repeated handling.

Mark Your Automotive Parts for Permanent Identification

did you know?

no-cost marking of your sample part with expert recommendations

Numberall: Engineered for Automotive Excellence in Marking Parts

Numberall’s metal marking equipment is specifically engineered to meet the rigorous demands of the automotive industry, offering distinct advantages that contribute to superior part identification:

- Proven Longevity: The indented marks created by Numberall machines exhibit exceptional resistance to wear, corrosion, and other forms of degradation. This ensures that critical identification data remains legible and intact throughout the entire lifespan of the automotive component, regardless of operational stresses.

- Guaranteed Compliance: Recognizing the stringent regulatory landscape of the automotive sector, Numberall’s marking solutions are designed to facilitate adherence to mandatory part identification and traceability standards. The indelible and depth of impression of our markings provides manufacturers with the confidence needed to meet traceability requirements.

- Unrivaled Precision and Accuracy: Numberall equipment excels in delivering highly precise and accurate markings, ensuring that every automotive component is marked with exactness and uniformity. This meticulous attention to detail eliminates the risks associated with misidentification, reducing errors, saving valuable production time, and minimizing potential costs related to rework or incorrect part usage.

- Adaptable Versatility: Understanding the diverse range of materials, shapes, and sizes of automotive parts, Numberall offers a versatile array of marking solutions. This adaptability allows manufacturers to select the optimal marking method for their specific application, ensuring that all marking needs are effectively met, from small fasteners to large engine blocks.

- Seamless Integration into Modern Production: Numberall’s marking systems are designed for effortless integration into contemporary automotive manufacturing processes. Our equipment can be seamlessly incorporated into automated production lines, minimizing disruption to workflow and maximizing overall efficiency, ensuring consistent and accurate marking at high production speeds.

What We Mark: Applications In Your Industry

The versatility of Numberall’s metal marking equipment allows for the permanent identification of a wide spectrum of automotive parts, including:

- Engine and Transmission Components: Marking blocks, heads, gears, shafts, and other critical internal parts for traceability and quality control.

- Chassis and Suspension Parts: Identifying control arms, struts, axles, and other structural components for safety and recall purposes.

- Fasteners and Hardware: Marking bolts, nuts, screws, and other small but critical components for inventory management and quality checks.

- Brake System Components: Identifying calipers, rotors, drums, and other safety-critical parts for traceability and regulatory compliance.

- Exhaust System Components: Marking manifolds, catalytic converters, and mufflers for emissions tracking and part identification.

- Body Panels and Structural Elements: Identifying specific body panels and structural members for manufacturing tracking and recall purposes.

- Electrical and Electronic Components: Marking housings, connectors, and other electronic parts for inventory and quality control.

Looking for a solution to marking your automotive parts?

Discover custom metal marking solutions for your automotive application. With our long history of innovation since 1930, we can meet any requirement. Request a Quote today!

Numberall: Your Partner in Automotive Part Identification

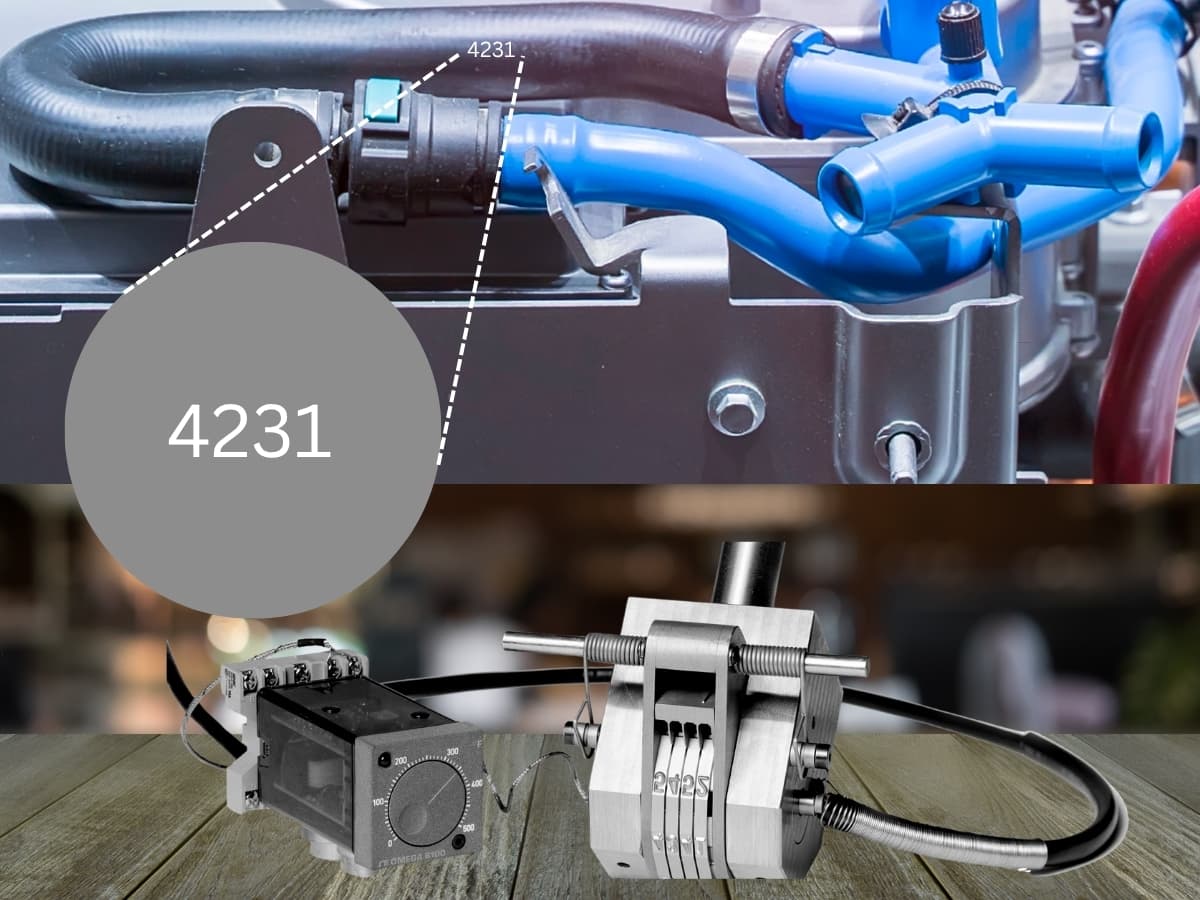

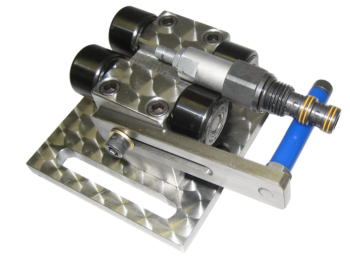

Numberall offers a comprehensive portfolio of metal marking equipment specifically engineered to meet the exacting standards of the automotive industry. Our legacy of durability, precision, and reliability makes us the ideal partner for ensuring permanent and effective part identification. Our solutions include:

- Robust Numbering Heads: Ideal for applying sequential serial numbers, date codes, and other variable data to automotive components on high-speed production lines, as exemplified by our field-proven Model 50P.

- Versatile Marking Presses: Providing consistent and high-force marking for a wide range of part sizes and materials, ensuring clear and lasting impressions. View our Bench Top Presses

- Durable Steel Stamps and Holders: For manual or semi-automated marking of specific codes, logos, or identification marks on various automotive parts.

- Custom Engineered Marking Solutions: Numberall’s engineering team can develop custom marking solutions designed for the unique requirements of specific automotive manufacturing processes and components.

By choosing Numberall, automotive manufacturers gain a partner committed to providing marking solutions that enhance traceability, improve quality control, ensure regulatory compliance, and ultimately contribute to the production of safer and more reliable vehicles.

Unmatched Benefits of Our Stamping Equipment

Customization

We offer tailored solutions to meet the unique marking requirements of your automotive parts.

Durability

Our stamping tools are designed to last, providing consistent performance even in demanding environments.

Precision

Ensure clear and accurate markings with our high-precision equipment.

Compliance

Meet industry standards and regulations with our reliable marking solutions.

Efficiency

Increase productivity with our easy-to-use and efficient stamping tools.

Support

Benefit from our exceptional customer service and technical support, ensuring your operations run smoothly.