Metal Marking for Electronic Components

Trusted since 1930 for American-made metal marking: The leader in electronic component product identification

Durable Markings

Our equipment ensures long-lasting and legible markings that withstand harsh environments.

Customizable Solutions

We offer custom marking solutions to meet the specific needs of your industry.

Efficient Operation

Designed for automatic operation and offering consistent and accurate markings.

Precision Metal Marking Solutions for Electronic Components

In the fast-paced electronics industry, accurate and durable component marking is paramount. It’s not just about identification; it’s about traceability, regulatory compliance, and safeguarding against counterfeiting. Numberall, a trusted US manufacturer with 90 years of expertise, delivers cutting-edge, customized metal marking solutions designed to meet these critical demands. We empower manufacturers to achieve excellence in their production processes by providing systems that ensure every component is marked with precision and permanence.

Numberall has been a trusted name in the electronics components industry for nearly a century. Our products are designed to meet the exacting demands of traceability, ensuring that components remain clear and legible throughout the product lifecycle.

Numberall Knows: Marking Electronic Components

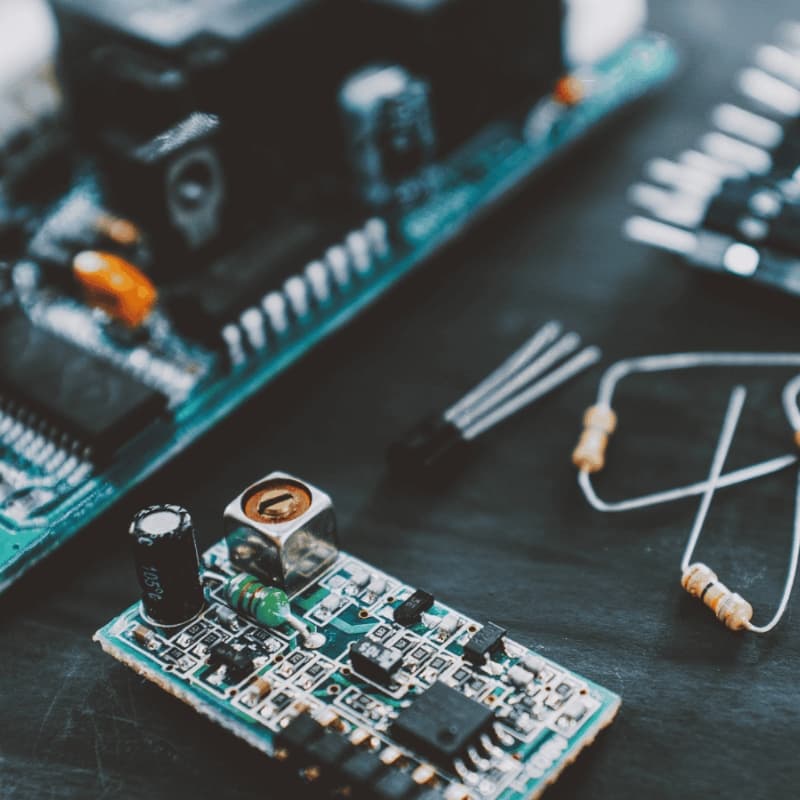

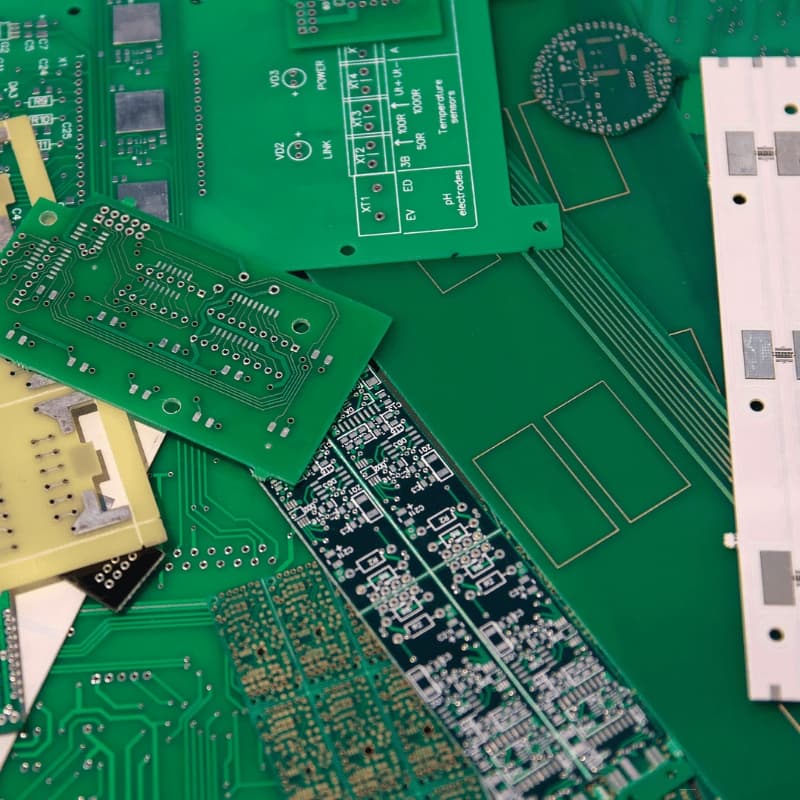

A customer with sensitive PCB’s needed a solution to safely mark their boards without deformation.

The Importance of Marking Electronic Components

Accurate marking is essential for electronic components for several key reasons:

- Traceability: Our solutions enable manufacturers to track components throughout the production lifecycle, ensuring rigorous quality control and facilitating efficient recalls when necessary.

- Compliance: We help you meet stringent industry regulations and standards by providing clear, durable, and compliant markings.

- Anti-Counterfeiting: Numberall’s permanent, tamper-proof markings are a critical defense against counterfeiting, protecting your brand and intellectual property.

- Quality Control: Marking allows for easy identification of components, making quality checks and defect tracking more efficient.

- Inventory Management: Proper marking simplifies inventory management, reducing errors and improving overall efficiency.

Mark Your Electronic Components for Permanent Identification

did you know?

no-cost marking of your sample part with expert recommendations

Numberall's Customized Marking Solutions

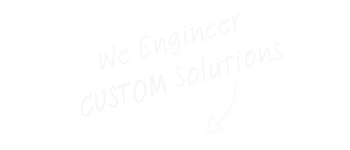

Numberall understands the unique challenges of the electronics industry. We offer a comprehensive range of marking machines, including numbering machines and type holders, that can be tailored to your specific needs. Our systems deliver the high precision, durability, and versatility required for marking a wide variety of electronic components, from delicate microchips to robust circuit boards. We don’t just sell machines; we provide solutions.

Numberall’s metal marking equipment provides distinct advantages:

- Unrivaled Precision and Clarity: Our equipment delivers high-contrast, permanent markings that are both machine and human-readable. This is essential for the intricate and often microscopic components in electronics manufacturing.

- Low-Stress Marking for Component Integrity: We utilize low-stress processes that minimize the risk of damage or alteration to delicate electronic components. Numberall’s low-stress characters ensure the integrity of your valuable products.

- Lasting Durability: Metal marking creates indelible marks by indenting the component’s surface. This method is exceptionally durable and resistant to wear, tear, and harsh environmental conditions.

- Versatility Across Materials: Our equipment handles a wide range of materials, including metals and plastics, making them ideal for marking diverse electronic components.

- Flexible Marking Options: Numberall offers flexibility in applying various markings, including barcodes, serial numbers, logos, and 2D Data Matrix codes, to meet your specific identification and traceability requirements.

- High-Speed Efficiency: Our machines are designed for high-speed marking, ensuring seamless integration into high-volume production environments and boosting your throughput.

Marking Your Electronic Components

Microcontrollers

Marking microcontrollers with unique serial numbers and barcodes ensures seamless traceability, enhancing quality control and simplifying the recall process if necessary.

Circuit Boards

Identifying circuit boards with part numbers and manufacturer information helps in quality control and facilitates repairs and replacements.

Connectors

Marking connectors with unique identifiers prevents counterfeiting and ensures the use of genuine components in assemblies.

Sensors

Marking sensors with calibration data and serial numbers aids in maintenance and ensures accurate performance.

Capacitors & Resistors

Identifying capacitors and resistors with value codes and manufacturer details ensures proper assembly and reduces the risk of errors.

Circuit Breakers

Marking circuit breaker with unique identifiers enhances operational efficiency by enabling quick and accurate identification during inspections and maintenance, thereby reducing downtime and improving overall system reliability.

Looking for a solution to marking your electronic components?

Discover custom metal marking solutions for your electronic component application. With our long history of innovation since 1930, we can meet any requirement. Request a Quote today!

Partner with Numberall for Precision Marking

In the demanding electronics industry, where precision, reliability, and compliance are paramount, Numberall’s customized marking solutions are the ideal choice. With nearly a century of experience, we are committed to providing electronic component manufacturers with high-quality, durable, and versatile marking systems.

Numberall offers a comprehensive range of products designed to address your electronic component identification needs, including:

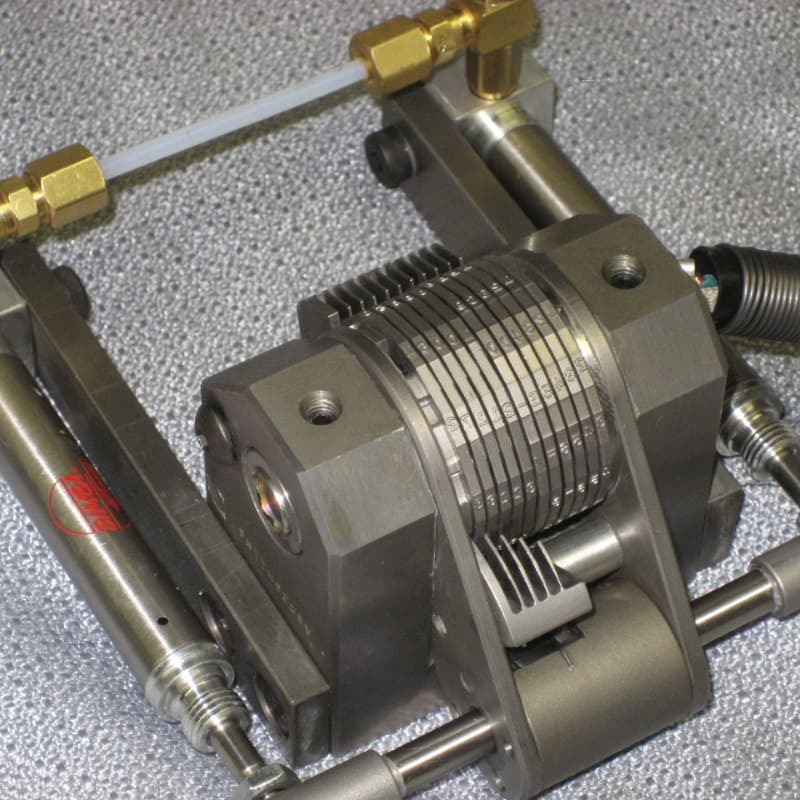

- Numbering Machines: Ideal for applying serial numbers, date codes, and other variable data with precision and speed.

- Type Holders and Insert Type: Provides flexibility for marking with alphanumeric characters, logos, and custom designs.

- Marking Presses: Delivers consistent and reliable marking force for various materials and component sizes.

Contact us today to discuss your specific needs and discover how Numberall can optimize your production processes, ensure traceability, and enhance the quality of your products.

Benefits of Numberall Marking Solutions in Electronics Manufacturing

Enhanced Traceability and Accountability

Our solutions ensure every component is accurately marked, providing a robust foundation for traceability and accountability throughout the production process and supply chain.

Improved Product Quality and Reliability

Permanent markings help maintain product integrity and quality, minimizing the risk of defects, counterfeits, and costly recalls.

Stronger Brand Protection

Tamper-proof markings protect against counterfeiting, safeguarding your brand reputation and ensuring that only genuine components are used.

Guaranteed Regulatory Compliance

Clear, permanent markings facilitate compliance with industry regulations (e.g., RoHS, REACH) and standards, reducing the risk of penalties and market access issues.

Streamlined Production

Error-free marking improves production efficiency.