by Daniel Bayerdorffer | Nov 18, 2021 | Non-Automatic, Numbering Heads

Need a Special Marking Sequence?

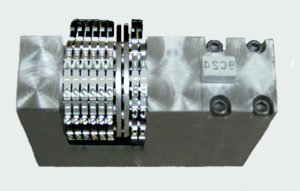

We can modify our marking heads to many different possibilities. The Model 70P pictured is a manually advanced numbering head with an extended frame leg. The extended leg has a pocket for a logo die. The customer needed a special space from the last wheel to the logo die. The logo die is retained by a set screw and can easily be removed for a different sequence. The wheels can be quickly rotated to a new sequence with the supplied spanner wrench.

Multiple Wheel Groups

Numberall can also make the Model 70 with 2 groups of wheels. The space between the groups is up to the customer. This design is also used when a lot of wheels are required. The frame leg allows for extra support for the wheels, to provide a good even impression.

These are just a couple of the many different modifications that can be done. We have extended both frame legs for inserts. We have made units with 3 groups of wheels. It all depends on the application and production requirements.

Similar modifications can be done to our Model 50 automatic marking heads. And to our hot stamping models, both automatic and manual.

As Always MADE IN USA!

Contact us now to discuss your specific project needs and how Numberall can help. 1-800-685-3072

by Daniel Bayerdorffer | Nov 18, 2021 | Automatic, Non-Automatic, Numbering Heads

Here’s a Unique Comparison

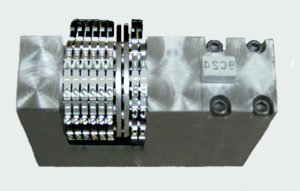

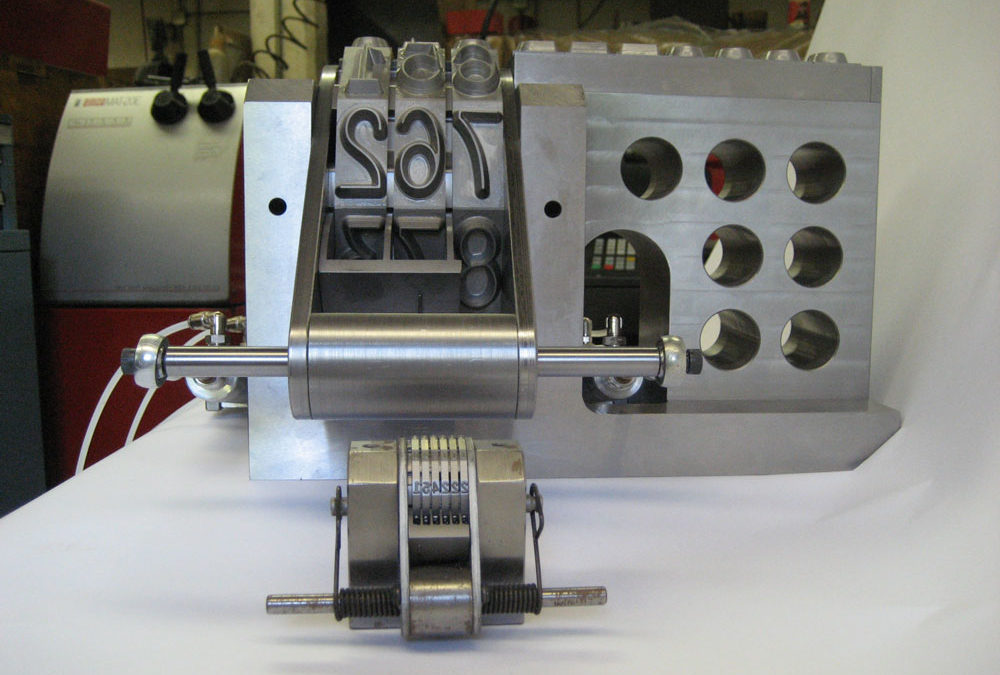

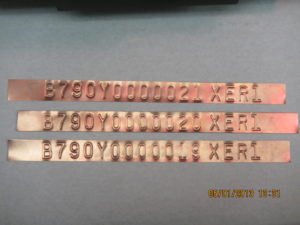

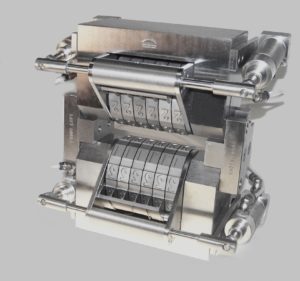

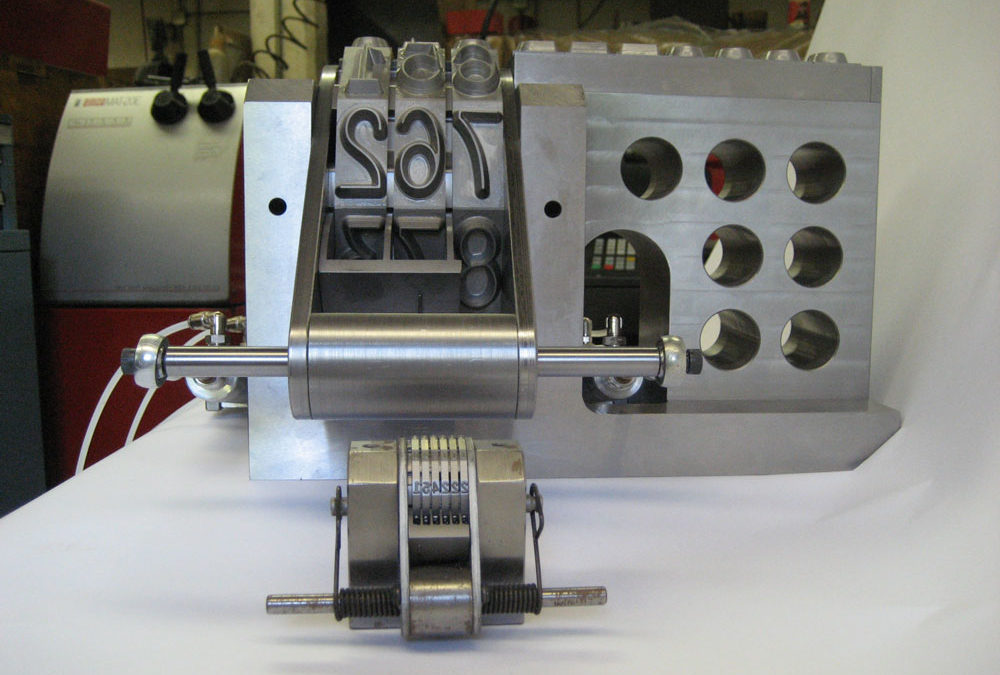

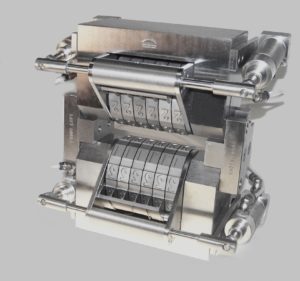

A custom Model 50P with 1-1/2″ characters and an extended frame leg with our standard Model 50P with 1/8″ characters in the foreground.

The custom Model 50P uses 7″ diameter wheels, the standard Model 50P uses 1-1/2″ diameter wheels. We make custom heads with up to 1-3/4″ character sizes. Our standard heads are available from 1/32″ to 3/8″ characters sizes.

The custom Model 50P is a 1 piece frame with an extended frame leg for 7 characters. Holes were drilled to help reduce weight. The air trip also required an unconventional mounting. A clearance hole was made for the air cylinder. Customer stamps up to 999 parts, then resets the wheels and changes the character arrangement on the frame leg. These are custom manufactured to the customers specifications. We can have up to 6 wheels indexed automatically, depending on character size.

Non-automatic heads with up to 1-3/4″ character sizes are also available.

As Always MADE IN USA!

Contact Numberall today for a quote. 1-800-685-3072

by Daniel Bayerdorffer | Sep 23, 2021 | Automatic, Numbering Heads, Uncategorized

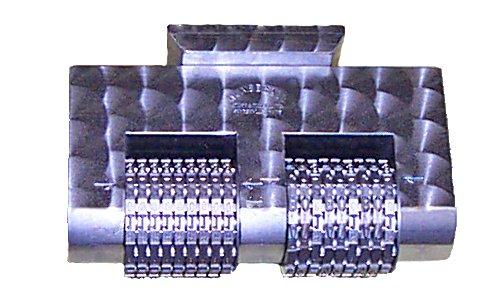

Numberall can produce equipment for Embossing or Debossing. The majority of our equipment is used for “identing”. However, if you need a raised character (like a vehicle license plate or Vin number) or a sunk character (the opposite side of a license plate), we can manufacture a numbering head or arrange one of our bench presses for embossing.

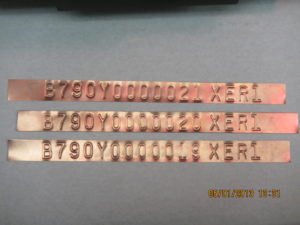

One picture is a set of our Model 50P for serial numbering. It was a large character size for a tag that had to be easily read. it was placed in the customers die set and the tags were automatically feed into the die set.

There is a group of pictures of our Model 50P for serial numbering, but the frame legs are extended for static information stamped with the serial number. This Model 50P set was totally custom. It was used in a die set to quickly produce tags to be used in a molding process. A picture of typical tags is included. Another picture shows a standard Model 50P along with the Embossing set. As you note, the Model 50P Embossing set is much larger that our standard Model 50P.

We can also modify our presses for 2 of the Model 23P type holders and type for embossing. This application was to produce a batch of tags with the same information, to process thru a galvanizing operation. The Type holders are easily removable to replace the male and female pieces of type. Shown is the Model 136 Hand Operated Press, tag fixture and 2 Model 23P Type Holders.

As always MADE IN USA!!

by Daniel Bayerdorffer | Jul 7, 2021 | Accessories, Hand Stamps

Numberall can make special holding fixtures for all their marking tools. For this application, the customer required a mark on the inside diameter (ID) of a piece of pipe. The ID range is 4″ to 8″. That allow us to make a block to insert the stamp. The block was then mounted to a shank of heat treated steel with a handle. Because the ID was large, the block fits into the diameter. The spacing of the block, allows the customer to mark the same distance from edge of the pipe regardless of the diameter. The large shank allow the operator to push against the diameter of the pipe and move the fixture till the stamp locates on the ID. The operator then uses a hammer blow to make the impression. As always MADE IN THE USA!

by Daniel Bayerdorffer | Jul 7, 2021 | Blog, Numbering Heads

Numberall can make non-automatic large character marking heads .Most applications are for our Model 50P or Model 250P for serial numbering. However, some applications require manual wheel advancement. Shown is a Model 270P with 5 wheels 3/4″ characters with a space for 4 inserts. Each wheel has a random sequence, customized just for this application. The space for 4 inserts is also used with a large logo. To rotate the wheels, a tool is inserted into the holes on the edges of the wheels. By moving the tool, you rotate each wheel to the desired sequence.. For this application the Model 270P is mounted into a hot stamp press with foil. The foil allows the impression to be colored. This custom head was designed and built in 7 weeks. As always MADE IN USA!

by Daniel Bayerdorffer | Dec 30, 2020 | Numbering Heads

Numberall can modify our marking tools to suit many applications. In this example the customer was stamping a part that needed to be a curved line. Also, clearance issues required a unique modification. The engraving not only had to be offset to produce a curved line, it had to be adjusted to stamp 30 degrees from normal. (more…)