August 20, 2025Metal Marking, Numbering & Lettering Presses

The Ultimate Benchtop Press for Metal Stamping

Model 40B: Durable Alternative to Geo T Schmidt Model 4 Manual Stamping Press

Need a durable manual metal stamping press for permanent, traceable marks? The Numberall Model 40B delivers reliable performance and ships in 24 hours, unlike the Geo T Schmidt Model 4’s weeks-long lead time. With 95 years of American craftsmanship, our presses are built for machine shops, locksmiths, HVAC contractors, and veterinarians.

Did You Know? Order Model 40B Today, Ships Tomorrow, beating competitor delays.

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Recent Posts

Why Numberall? Durable and Reliable

Since 1930, our family business has built presses that last decades, servicing machines over 40 years old. Key benefits:

- Fast Delivery: In-stock Model 40B ships in 24 hours, same-day by 1 PM EST.

- Lifetime Support: Unmatched reliability and support, even after 40 years, our machines are still operating.

- Cost Savings: No power or consumables, unlike costly laser/inkjet systems.

- Traceable Marks: Deep indents meet AIAG standards, outlasting inkjet in harsh conditions. AIAG Traceability

User Impact: Businesses rely on Model 40B’s durable marks and Next Day shipping for quick project starts.

did you know?

no-cost marking of your sample part with expert recommendations

Why Manual Over Laser or Inkjet?

Unlike laser (costly, complex) or inkjet (fading marks), manual indentation excels for:

- Fast Availability: 24-hour delivery vs. weeks, enabling quick project starts.

- Durability: Marks last 5x longer in moisture or heat, ideal for veterinary tags or HVAC per USDA standards. USDA Traceability

- Affordability: Perfect for small runs of tags or serial numbers.

- Simplicity: No power needed, thriving in remote or rugged settings.

Need deeper marks on harder metals? Our Model 94 delivers heavy-duty precision. Explore Model 94

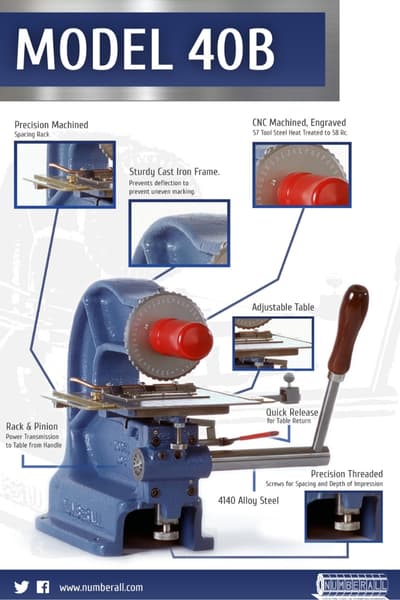

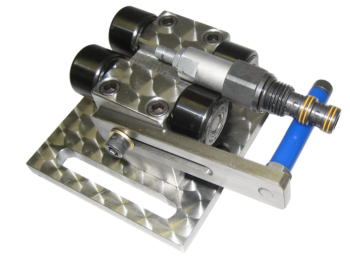

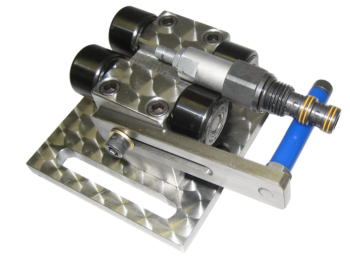

Model 40B: Portable Powerhouse

At 40 lbs, the Model 40B is ideal for dog tags, badges, or labels:

- Materials: Aluminum, brass, mild steel, stainless (up to 1/8” characters).

- Features: Cast iron frame, 42-character dial, simple operation.

- Demo: See it in action in our Model 40B Demo Video

Model 40B vs. Geo T Schmidt Model 4

| Feature | Numberall Model 40B | Geo T Schmidt Model 4 |

| Lead Time | 24 hours | Weeks (varies) |

| Weight | 40 lbs | 28.5 lbs (net) |

| Table Size | 6″ x 8.5″ | 7.75″ x 9.75″ |

| Part Size | 5.75″ wide, unlimited height | 4″ deep, 8″ wide |

| Part Thickness | Up to 3/8″ (without clamp) | 0.012 to 0.093 inch |

| Character Heights | 1/16″ to 3/16″ | 3/32″ to 1/4″ |

| Guarantee | Lifetime Support | Standard |

Source: Geo T Schmidt Model 4 specs.

Note: Model 40B’s thickness range suits diverse needs.

Model 40B Stamping Press

Weight 40 lbs

Best Use: Tags, keys, flat parts

Typical Materials: Aluminum, Brass, Mild Steel

Main Advantage: Portability, ease of use

Model 94 Heavy Duty Stamping Press

Weight 120 lbs

Best Use: Thicker parts, harder materials

Typical Materials: Stainless Steel, Harder Metals

Main Advantage: More force, larger characters

Who Uses Numberall?

- Locksmiths/Veterinarians: Durable dog tags, badges.

- HVAC/Marine: Tags for harsh environments.

- Machine Shops: Serial numbers, custom parts.

Free Guide: Manual vs. Inkjet – Pros & Cons

Compare marking methods. Browse Here

Sources

• AIAG Supply Chain Standards

• USDA Animal Disease Traceability

Ready to get a quote? Our team responds to all inquiries within 24 hours to ensure you get the perfect solution, not just a product.

Download Our Model 40B Infographic

Download our free Model 40B Infographic. It’s a single-page visual guide that highlights key specs, benefits, and applications, so you can easily share it with your team or keep it on hand for quick reference.

Download will be sent to your email asap.

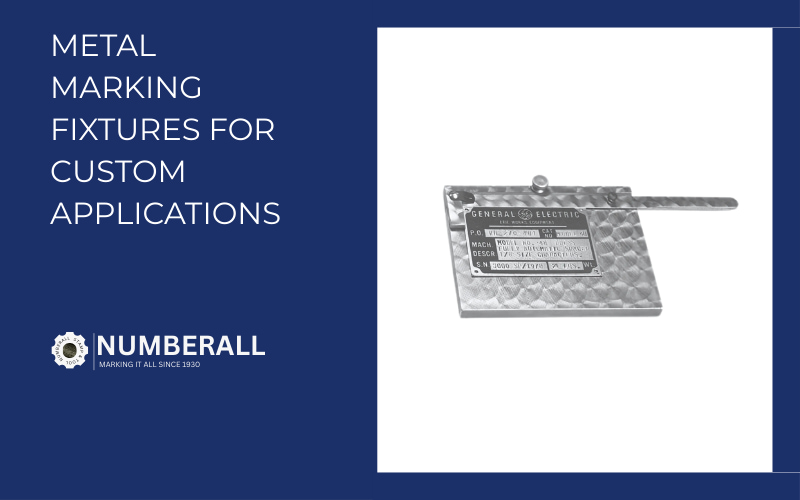

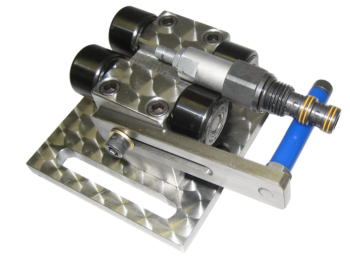

Looking for an economical custom solution to marking your equipment?

Discover custom metal marking solutions for your equipment. With our long history of innovation since 1930, we can meet any requirement. Making it easy to do business with us. Request a Quote today!

Recent Posts

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

August 20, 2025Metal Marking, Numbering & Lettering Presses

The Ultimate Benchtop Press for Metal Stamping

Hot Stamping for Manufacturing: A Guide to Permanent, High-Quality Marking

In the competitive world of manufacturing, clear, durable, and traceable marking is not just an option—it’s a necessity. For businesses that require a marking solution on a variety of materials, from hard plastics to soft leather, traditional stamping methods often fall short. This is where hot stamping comes in.

At Numberall, we understand the complexities of modern manufacturing. As a 4th-generation family business since 1930, we’ve built a reputation for providing robust, custom-engineered metal marking equipment. This expertise extends to hot stamping capabilities, offering a versatile and permanent solution for countless industries.

This comprehensive guide will walk you through the fundamentals of hot stamping, its key applications, and how Numberall’s specialized equipment can be the perfect fit for your business.

What is Hot Stamping? A Manufacturing Perspective

Hot stamping is a dry marking process that uses a heated die and pressure to create a crisp, lasting impression. Unlike cold stamping, which can be difficult to read on some materials, hot stamping provides a clean, highly visible mark.

For manufacturers and other businesses needing a reliable marking solution, hot stamping offers significant advantages:

- Permanent & Durable: The mark is embedded into the material, making it resistant to abrasion, chemicals, and extreme temperatures.

- Versatile Material Compatibility: It’s effective on a wide range of substrates, including plastics, rubber, leather, wood, and even certain coated metals.

- High-Quality Finish: Hot stamping can create a clear, branded impression or, with the use of a foil, add a vibrant color for enhanced visibility.

- Reduced Material Stress: Unlike the aggressive force of cold stamping, hot stamping applies a combination of heat and pressure. This process can be less stressful on the material, making it an excellent choice for marking sensitive or thin-walled parts that might be prone to cracking or distortion from the impact of a standard indenting process.

For businesses currently using ink marking or labels that are prone to wear and tear, hot stamping is the ultimate upgrade for product longevity and brand integrity.

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Recent Posts

Hot Stamping Applications & Key Benefits

Hot stamping provides a solution for a variety of common challenges faced by manufacturers, and is an excellent choice for a wide range of applications, especially where durability, a high-end aesthetic, or security is a priority.

1. Permanent Branding & Traceability

When you need a part code, serial number, or logo that will outlast the product itself, hot stamping is the answer. It creates a deep, color-free mark that is legible and durable, even in harsh industrial environments.

An excellent example of this is hot stamping plastic cattle tags. These tags are exposed to extreme weather, dirt, and constant friction. Hot stamping, combined with specialized foils, creates a visible and permanent impression that is essential for managing farm animals and ensuring traceability for years. This application demonstrates the kind of long-lasting, reliable mark that only a durable process like hot stamping can provide.

- Common uses: Marking part numbers on plastic handles, branding logos on rubber tubing, or serializing electrical connectors for quality control.

- Benefit for your business: Ensures long-term traceability and brand recognition, crucial for industries with strict regulations.

2. Adding Color with Foil Stamping

To make your mark truly stand out, foil stamping is an ideal option. This process transfers a thin layer of colored foil using heat and pressure, creating a vivid, eye-catching mark.

- Common uses: Color-coding parts for easy identification, adding a metallic logo to a product, or marking safety warnings in a highly visible color.

- Benefit for your business: Improves operational efficiency with color-coded parts and enhances product aesthetics and perceived value.

3. Marking Non-Metallic Materials

Hot stamping expands the capabilities of your marking operations, allowing you to mark a diverse portfolio of materials with a single piece of equipment. This eliminates the need for multiple machines and simplifies your production line.

- Common uses: Marking on automotive interior and exterior parts, medical devices, leather goods, and electronic components.

- Benefit for your business: Increases operational flexibility and reduces capital investment by consolidating marking processes.

did you know?

no-cost marking of your sample part with expert recommendations

Numberall's Hot Stamping Equipment: The Custom Solution You Need

At Numberall, we don’t just sell machines; we provide solutions. Our hot stamping product line is engineered to be reliable, adaptable, and integrated seamlessly into your existing operations. We specialize in custom configurations to meet the unique demands of your application.

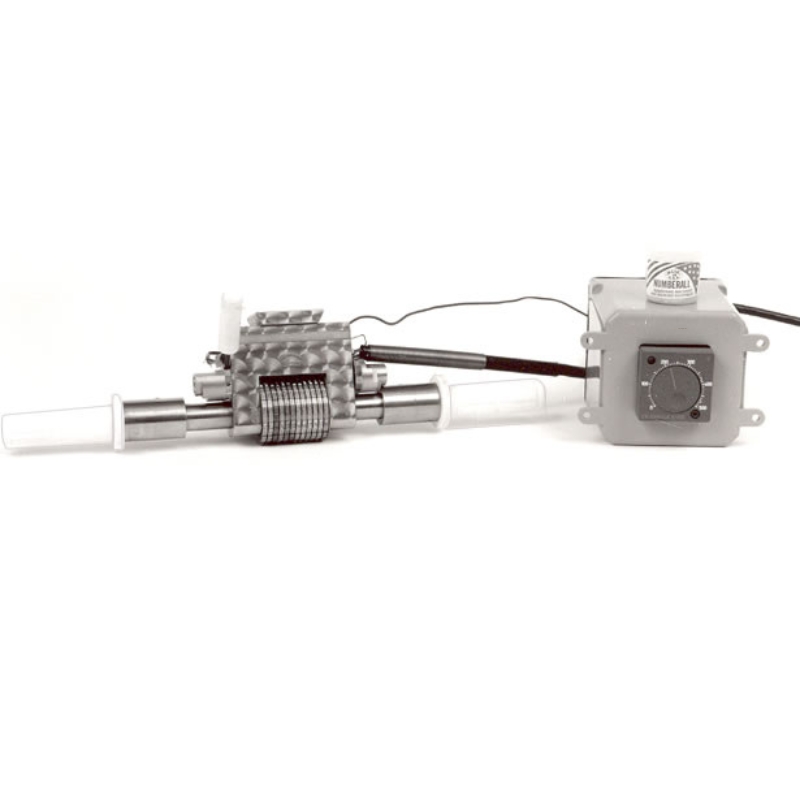

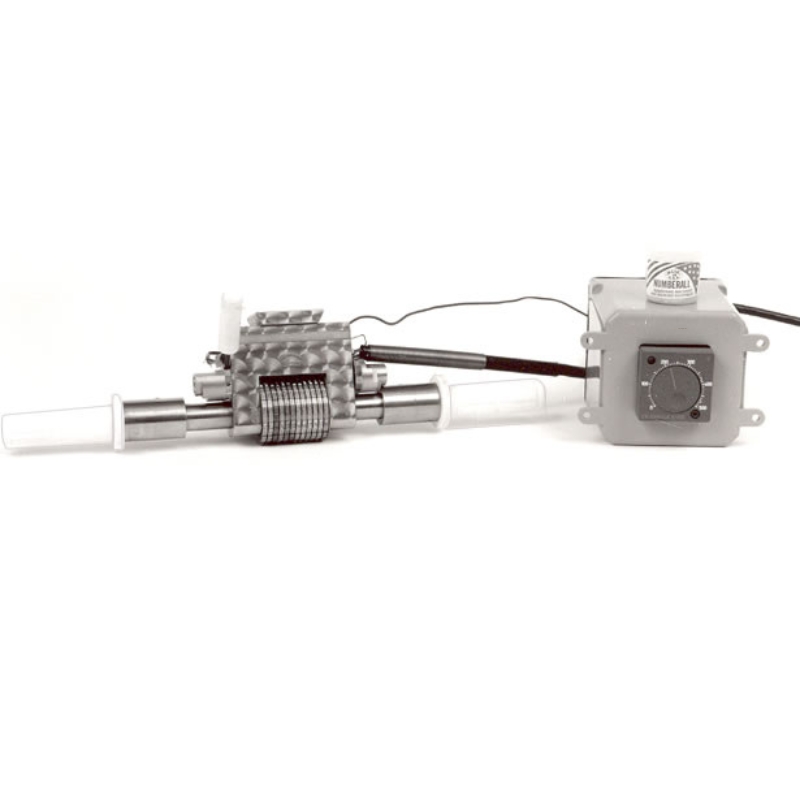

Hot Stamping Numbering Heads & Machines

Our hot stamping numbering heads are the go-to choice for businesses that require sequential or semi-consecutive numbering. These robust, heavy-duty devices can be mounted in a press and are equipped with internal heating elements for consistent, high-quality marks.

- Model 270P Hot Stamping Numbering Head: A benchmark for precision and durability, this numbering head is a versatile tool for a wide range of marking applications.

- Model 280P, 283P, & 285P Hot Stamping Numbering Heads/Machines: These semi-automatic machines offer enhanced speed and efficiency, perfect for high-volume production lines. Features like insulated knobs allow for quick and safe character changes.

- Model 250P Hot Stamping Numbering Head/Machine: The workhorse of our lineup, the Model 250P is built for demanding applications and is often the basis for our fully custom solutions.

Hot Stamping Type Holders

For marking a fixed code, logo, or a non-sequential series of characters, our type holders are the ideal choice. They provide a secure and stable platform for individual steel type characters.

- Model 223P Hot Stamping Type Holder: Specifically designed for hot stamping, this holder comes with a built-in heating element to ensure perfect hot stamp impressions on every part.

Why Choose Numberall? The Brand to Trust Since 1930

For over 90 years, Numberall has been a leading manufacturer of metal marking equipment. Our longevity is a testament to our commitment to quality and our ability to innovate while upholding our core values as a 4th-generation family business. We don’t believe in a one-size-fits-all approach.

Our extensive product configuration process reflects our dedication to understanding your unique needs and delivering a tailored solution that provides a true value exchange.

Ready to improve your marking process with a durable, efficient, and custom hot stamping solution?

Browse our Industry Pages and Case Studies to see how we’ve helped businesses just like yours.

Looking for an economical custom solution to marking your equipment?

Discover custom metal marking solutions for your equipment. With our long history of innovation since 1930, we can meet any requirement. Making it easy to do business with us. Request a Quote today!

Recent Posts

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

August 20, 2025Metal Marking, Numbering & Lettering Presses

The Ultimate Benchtop Press for Metal Stamping

Hot Stamping for Manufacturing: A Guide to Permanent, High-Quality Marking

In the competitive world of manufacturing, clear, durable, and traceable marking is not just an option—it’s a necessity. For businesses that require a marking solution on a variety of materials, from hard plastics to soft leather, traditional stamping methods often fall short. This is where hot stamping comes in.

At Numberall, we understand the complexities of modern manufacturing. As a 4th-generation family business since 1930, we’ve built a reputation for providing robust, custom-engineered metal marking equipment. This expertise extends to hot stamping capabilities, offering a versatile and permanent solution for countless industries.

This comprehensive guide will walk you through the fundamentals of hot stamping, its key applications, and how Numberall’s specialized equipment can be the perfect fit for your business.

What is Hot Stamping? A Manufacturing Perspective

Hot stamping is a dry marking process that uses a heated die and pressure to create a crisp, lasting impression. Unlike cold stamping, which can be difficult to read on some materials, hot stamping provides a clean, highly visible mark.

For manufacturers and other businesses needing a reliable marking solution, hot stamping offers significant advantages:

- Permanent & Durable: The mark is embedded into the material, making it resistant to abrasion, chemicals, and extreme temperatures.

- Versatile Material Compatibility: It’s effective on a wide range of substrates, including plastics, rubber, leather, wood, and even certain coated metals.

- High-Quality Finish: Hot stamping can create a clear, branded impression or, with the use of a foil, add a vibrant color for enhanced visibility.

- Reduced Material Stress: Unlike the aggressive force of cold stamping, hot stamping applies a combination of heat and pressure. This process can be less stressful on the material, making it an excellent choice for marking sensitive or thin-walled parts that might be prone to cracking or distortion from the impact of a standard indenting process.

For businesses currently using ink marking or labels that are prone to wear and tear, hot stamping is the ultimate upgrade for product longevity and brand integrity.

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Recent Posts

Hot Stamping Applications & Key Benefits

Hot stamping provides a solution for a variety of common challenges faced by manufacturers, and is an excellent choice for a wide range of applications, especially where durability, a high-end aesthetic, or security is a priority.

1. Permanent Branding & Traceability

When you need a part code, serial number, or logo that will outlast the product itself, hot stamping is the answer. It creates a deep, color-free mark that is legible and durable, even in harsh industrial environments.

An excellent example of this is hot stamping plastic cattle tags. These tags are exposed to extreme weather, dirt, and constant friction. Hot stamping, combined with specialized foils, creates a visible and permanent impression that is essential for managing farm animals and ensuring traceability for years. This application demonstrates the kind of long-lasting, reliable mark that only a durable process like hot stamping can provide.

- Common uses: Marking part numbers on plastic handles, branding logos on rubber tubing, or serializing electrical connectors for quality control.

- Benefit for your business: Ensures long-term traceability and brand recognition, crucial for industries with strict regulations.

2. Adding Color with Foil Stamping

To make your mark truly stand out, foil stamping is an ideal option. This process transfers a thin layer of colored foil using heat and pressure, creating a vivid, eye-catching mark.

- Common uses: Color-coding parts for easy identification, adding a metallic logo to a product, or marking safety warnings in a highly visible color.

- Benefit for your business: Improves operational efficiency with color-coded parts and enhances product aesthetics and perceived value.

3. Marking Non-Metallic Materials

Hot stamping expands the capabilities of your marking operations, allowing you to mark a diverse portfolio of materials with a single piece of equipment. This eliminates the need for multiple machines and simplifies your production line.

- Common uses: Marking on automotive interior and exterior parts, medical devices, leather goods, and electronic components.

- Benefit for your business: Increases operational flexibility and reduces capital investment by consolidating marking processes.

did you know?

no-cost marking of your sample part with expert recommendations

Numberall's Hot Stamping Equipment: The Custom Solution You Need

At Numberall, we don’t just sell machines; we provide solutions. Our hot stamping product line is engineered to be reliable, adaptable, and integrated seamlessly into your existing operations. We specialize in custom configurations to meet the unique demands of your application.

Hot Stamping Numbering Heads & Machines

Our hot stamping numbering heads are the go-to choice for businesses that require sequential or semi-consecutive numbering. These robust, heavy-duty devices can be mounted in a press and are equipped with internal heating elements for consistent, high-quality marks.

- Model 270P Hot Stamping Numbering Head: A benchmark for precision and durability, this numbering head is a versatile tool for a wide range of marking applications.

- Model 280P, 283P, & 285P Hot Stamping Numbering Heads/Machines: These semi-automatic machines offer enhanced speed and efficiency, perfect for high-volume production lines. Features like insulated knobs allow for quick and safe character changes.

- Model 250P Hot Stamping Numbering Head/Machine: The workhorse of our lineup, the Model 250P is built for demanding applications and is often the basis for our fully custom solutions.

Hot Stamping Type Holders

For marking a fixed code, logo, or a non-sequential series of characters, our type holders are the ideal choice. They provide a secure and stable platform for individual steel type characters.

- Model 223P Hot Stamping Type Holder: Specifically designed for hot stamping, this holder comes with a built-in heating element to ensure perfect hot stamp impressions on every part.

Why Choose Numberall? The Brand to Trust Since 1930

For over 90 years, Numberall has been a leading manufacturer of metal marking equipment. Our longevity is a testament to our commitment to quality and our ability to innovate while upholding our core values as a 4th-generation family business. We don’t believe in a one-size-fits-all approach.

Our extensive product configuration process reflects our dedication to understanding your unique needs and delivering a tailored solution that provides a true value exchange.

Ready to improve your marking process with a durable, efficient, and custom hot stamping solution?

Browse our Industry Pages and Case Studies to see how we’ve helped businesses just like yours.

Looking for an economical custom solution to marking your equipment?

Discover custom metal marking solutions for your equipment. With our long history of innovation since 1930, we can meet any requirement. Making it easy to do business with us. Request a Quote today!

Recent Posts

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.