Model 94 Heavy-Duty Numbering & Lettering Press

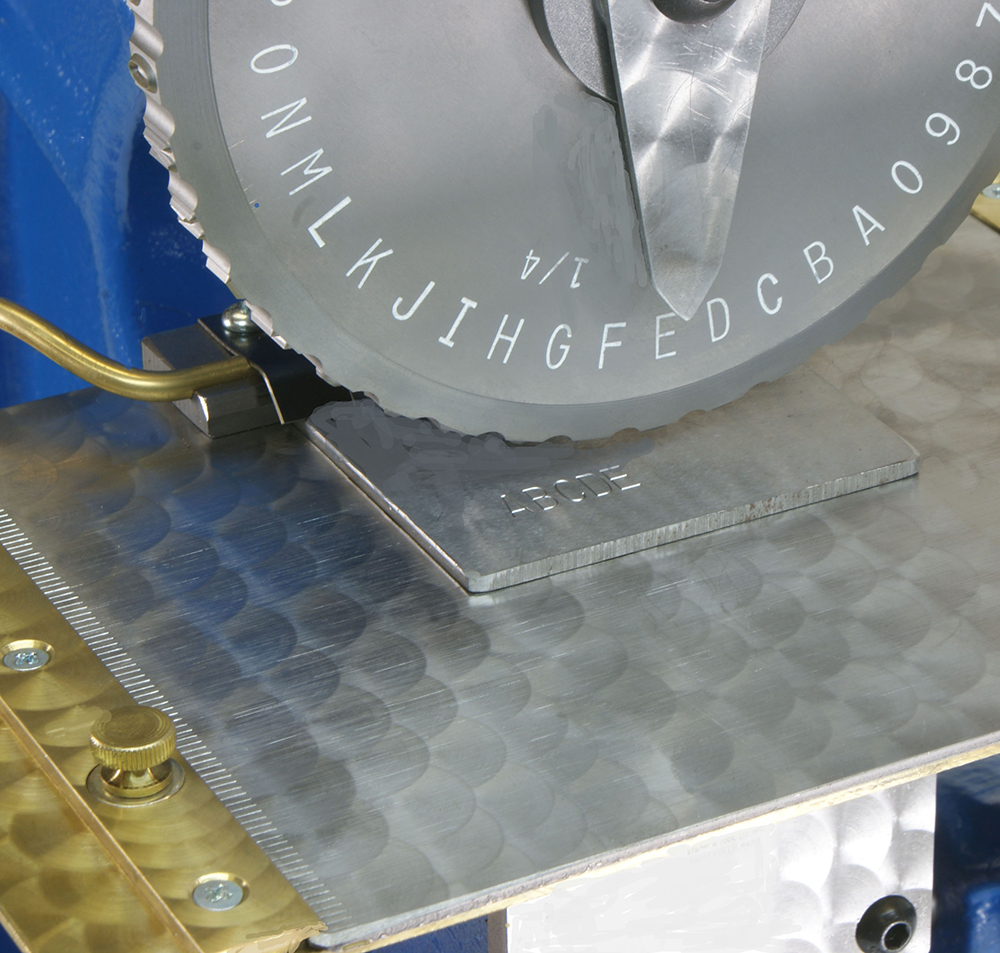

The Numberall Model 94 Heavy Duty Numbering and Lettering Press offers robust performance for precision stamping on nameplates. Its heavy-duty frame and adjustable pressure settings ensure clear, consistent marks on various materials. Perfect for high-volume tasks, the Model 94 delivers durable, legible impressions, enhancing traceability and product identification in industrial applications.

- Durable Construction

- Lifetime Support

- Custom Options Available

| Weight | 120 lbs |

|---|---|

| Dimensions | 28 × 18 × 24 in |

| Character Size | 1/8", 5/32", 3/16", 1/4", 5/16", 3/8" |

| Product Details | Interchangeable Dials |

Price range: $5,299.00 through $5,636.00

Need a custom quote?

Product Resources

Catalog Request

Product Manual (PDF)

Length of Impression Ruler (PDF)

Operation

- The operation of the Model 94 is designed for simplicity. Depth of impression is adjustable by a dial on the bottom of the press.

- The table is adjusted up or down for the proper depth. The operator rotates the dial and pulls the lever to stamp the chosen character.

- Upon releasing the lever, the table spaces one character space. The procedure is repeated until the line is completed. A "half stroke" of the lever produces a blank space.

- The table insert is moveable in or out without disturbing the clamped parts.

- Graduated lines are stamped into the left side of the table insert in 1/16" increments. An arrow is stamped into the guide rail to be used as a reference point.

- There is a stop for setting the left hand margin. At the end of the line, the operator depresses the lever a half stroke.

- The table can then be moved to the right manually, against the margin stop.

Construction & Parts

- The character wheels are engraved for accuracy, strength and alignment. Crafted from high grade tool steel, they are precision heat treated for severe usage and long life. Heavy duty cast iron construction is used throughout the machine. All parts are machined and no die cast parts are used. Various nests, strip holders and slides can be custom manufactured for use with the Model 94. Please contact us for more information.

[youtube https://www.youtube.com/watch?v=7xkhVkfJVSk]

Optional Fixtures

• Model 113 Strip Holder

• Universal Key Nest

• Custom Nest

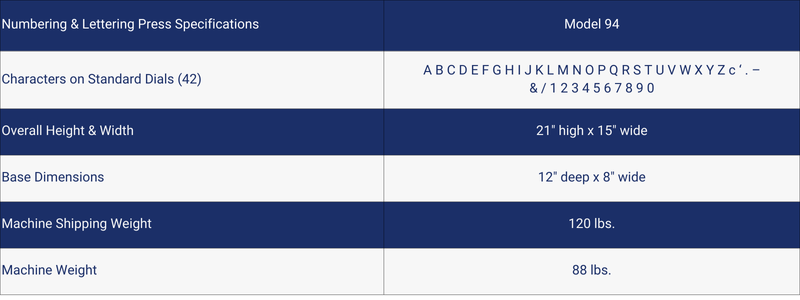

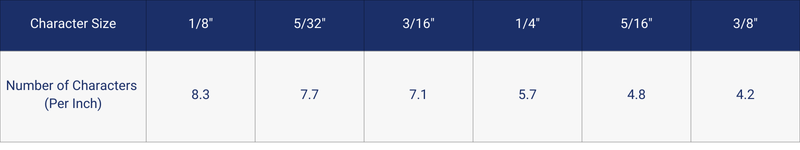

Product Specifications

Available Spacing

Different size dials are interchangeable, but each size character requires a different spacing rack.

Additional information

| Weight | 120 lbs |

|---|---|

| Dimensions | 28 × 18 × 24 in |

| Character Size | 1/8", 5/32", 3/16", 1/4", 5/16", 3/8" |

| Product Details | Interchangeable Dials |