Description

Branding

Branding

Branding is an application that requires a part code or serial number with no color (decorating). It is usually applied in situations where it is not required that the end-user easily see the marking or when it is not feasible to use inking or paper labels. Since it is indented into the product, it will remain visible as long as the product remains intact, whereas inks or paper labels cannot survive harsh environments. The indented code stamped on typical automotive electrical connectors is a common part that is stamped by branding that can withstand such conditions.

Adding Color or Decoration

Adding Color or Decoration

Some applications that require the end-user to readily identify the code may add color or decoration to enhance the indented surface. This particular application requires the use of a Hot Stamping Press with foil. The foil is used as a transfer medium for adding color to the sequence. Typically, Flat Face Gothic characters are used, since a broad face facilitates the transfer of color. Numberall does not manufacture or offer a Hot Stamping Press with foil. Although, in certain situations, Numberall’s Bench Marking Presses can be used with a heated Marking Device to “brand” the product. Any of Numberall’s Marking Devices can be used with other manufacturers’ Hot Stamp Presses.

Necessary Modifications

Necessary Modifications

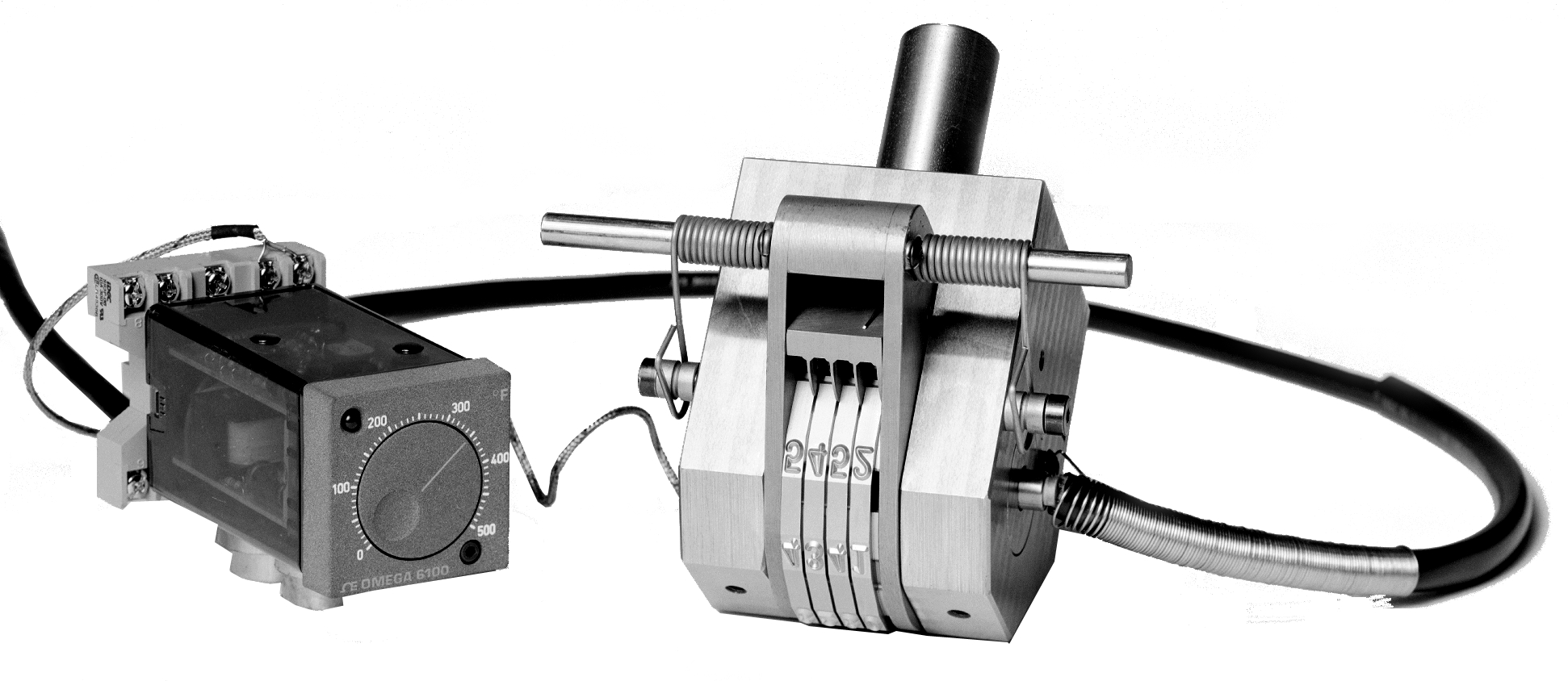

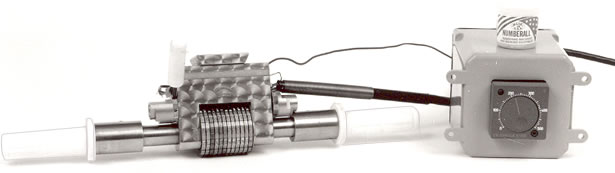

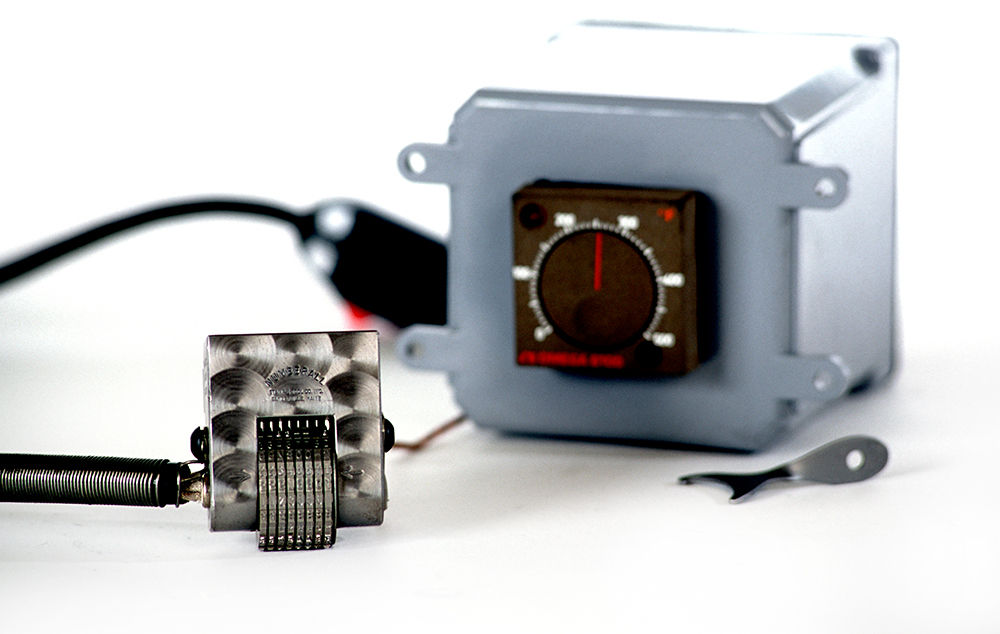

To allow for hot stamping, the marking device must first be modified in several ways. Additional clearance must be allowed for heat growth, and heating elements should be provided. On the Models 250 and 270, the heating element is located in the wheel shaft. On the Models 280, 283, 285 and 223, 2¼” diameter heaters are installed in the frame. When using these marking devices in a Hot Stamp Press, it is recommended that the provided heaters be utilized. Particularly for the Model 250P, the heater will help the marking device to maintain a constant temperature.

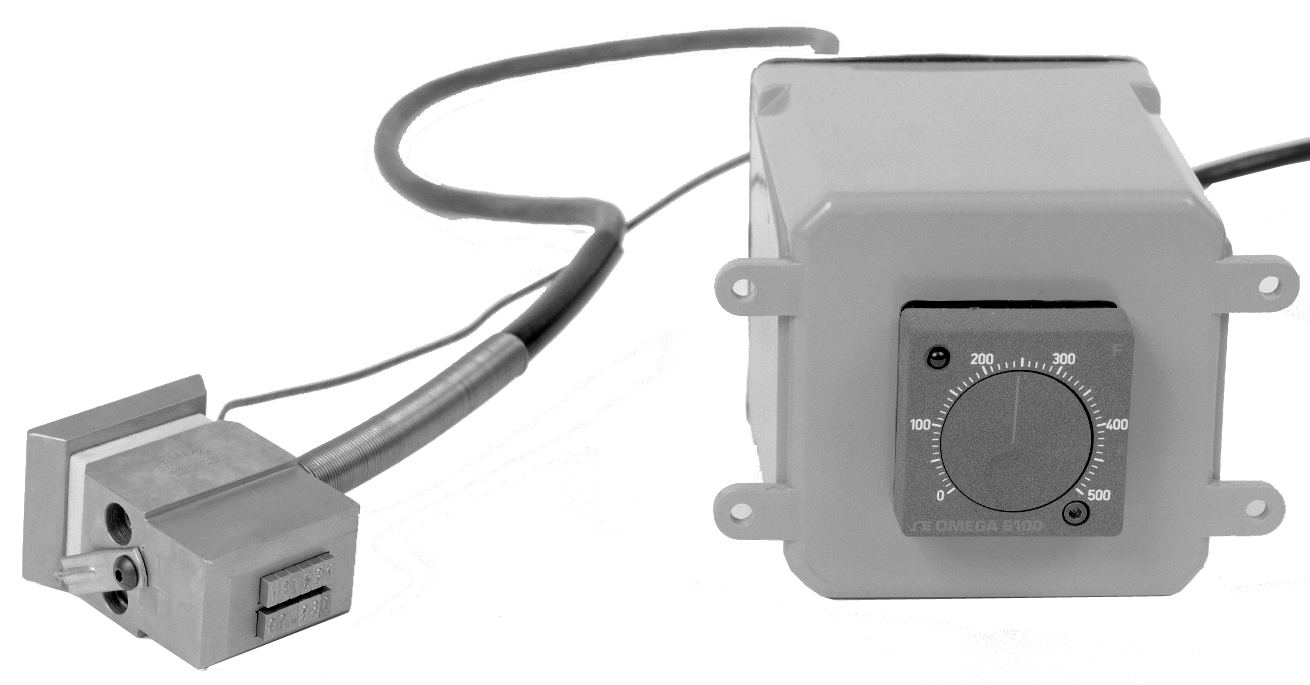

It is strongly recommended that the heater that is provided with the marking device be wired to the temperature controller of the Hot Stamp Press, or the Optional Proportional Temperature Control be purchased. Heating the marking device via the hot plate of the Hot Stamping Press requires the top of the numbering head to be much hotter than the wheels in order to transfer an adequate amount of heat. This method may bind the unit, due to uneven heat growth.

Hot Stamping Equipment Accessories

There are many accessories available for heated marking devices. If the device is used in a regular press, an insulated mounting plate must be used. An insulated mounting plate, between the press ram head and the shank, prevents any transfer of heat. The Models 283, 285, and 280 have insulated knobs, thereby allowing the operator to turn the wheels by hand.

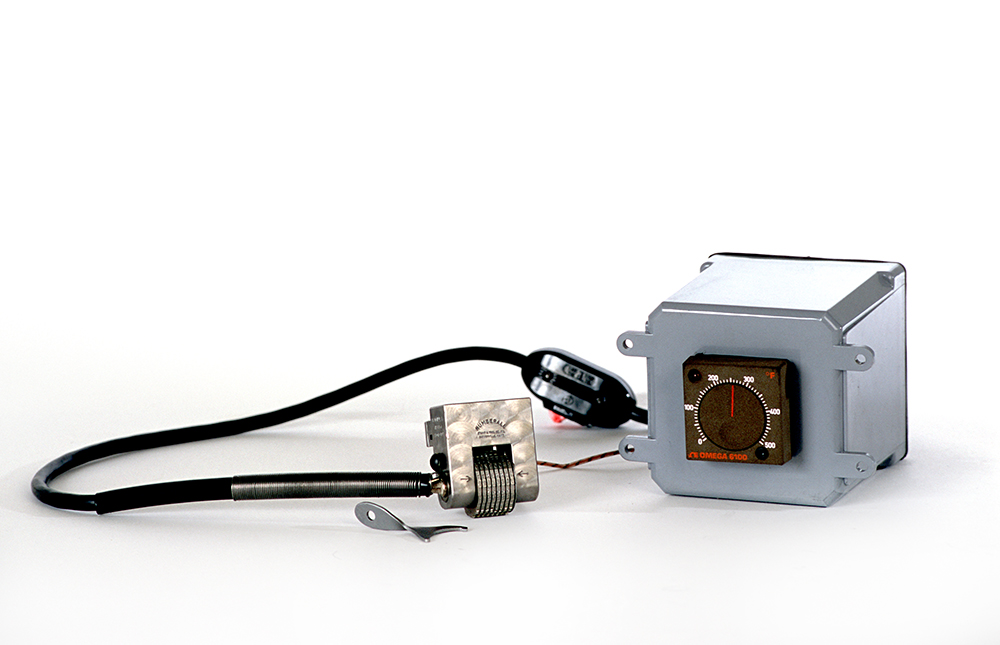

Heating elements, a cord and switch for 110V control are included with the Hot Stamping Option. A temperature control is not included, but is highly recommended. Numberall’s Hot Stamping Marking Devices are designed to operate at 350°F and below. Higher temperatures may be obtained, but it is recommend that you first check with the factory to ensure suitability. A Numbering Head that has been damaged due to overheating is not covered under warranty. There are additional accessories that may be provided, depending on the particular model that is requested.

Maintenance

A maintenance schedule is recommended for all hot stamping devices. The hot stamping of plastics creates a residue on the device, which, when combined with high temperatures, increases the rate of oxidation. Numberall’s Special High-Temperature Grease, which is supplied with all hot stamping equipment, prevents corrosion and provides lubrication. The grease is also available for purchase separately. A clean machine is a must.