Metal Marking for the Aviation Industry

Trusted since 1930 for American-made metal marking: The leader in aviation part identification

Durable Markings

Our equipment ensures long-lasting and legible markings that withstand harsh environments.

Customizable Solutions

We offer custom marking solutions to meet the specific needs of your industry.

Efficient Operation

Designed for automatic operation and offering consistent and accurate markings.

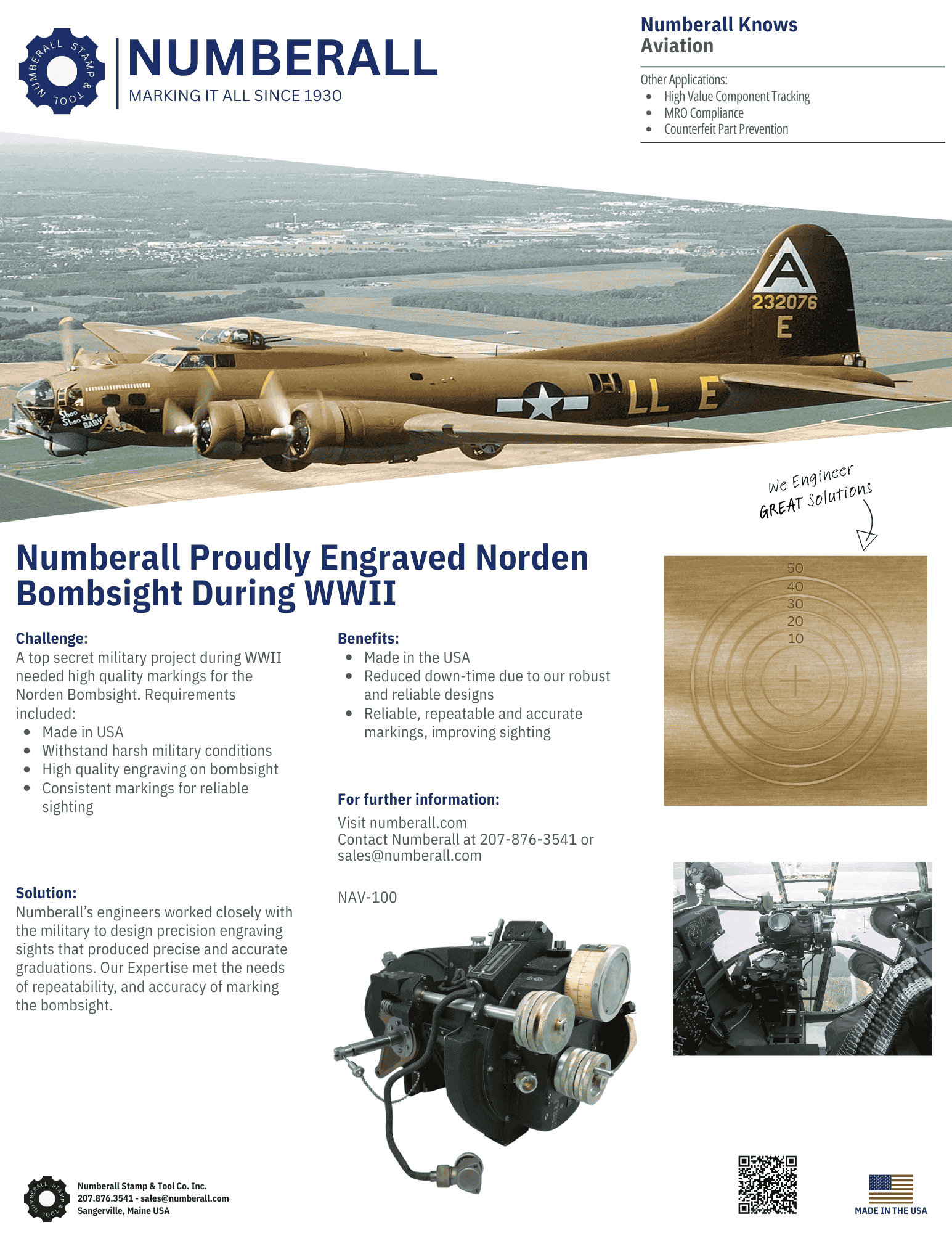

Norden Bombsight installed in a B-25 WWII Bomber. Numberall indented parts for the bombsight with our industry leading numbering heads.

Durable Aviation Part Marking: Essential for Aircraft Component Traceability

Achieving verifiable, permanent identification on aviation parts and components is absolutely crucial for safety, regulatory compliance, maintenance efficiency, and supply chain integrity. In a sector where the failure of a single part can have catastrophic consequences, indelible industrial marking is not just important – it’s mandatory. Metal marking with precision tools, including numbering heads and other robust solutions, provides the indispensable durability needed for permanent identifiers on critical aerospace substrates, ensuring cradle-to-grave traceability for every aircraft component.

Numberall has a long-standing history in providing robust marking solutions for demanding industries. Our products are engineered to meet the rigorous demands of aviation part identification and traceability, ensuring that crucial codes remain clear and legible throughout an aircraft part’s operational life and through demanding MRO (Maintenance, Repair, and Overhaul) processes.

Numberall Knows: Marking Aviation Equipment

A historical study of the Norden Bombsight manufacturer needed a solution to meet exacting specifications of their top secret WWII bombsight.

Why Durable Metal Marking is Critical for Aviation Parts

Implementing robust marking techniques like those using Numberall solutions provides foundational benefits that protect safety, ensure compliance, and streamline operations across the aerospace sector:

- Permanent and Durable Marks: Unlike temporary labels or inks that can be removed, fade, or become illegible due to extreme temperatures, chemicals, vibration, abrasion, or cleaning agents common in aviation environments, indent marking creates permanent indentations. This durability guarantees aircraft component traceability throughout the entire lifecycle of an aircraft, from manufacturing and assembly through countless flight hours and MRO cycles. This is critical for safety, quality control, and stringent regulatory compliance (e.g., FAA, EASA, AS9100, MIL-STD-130).

- Enhanced Part Security & Anti-Counterfeiting: Applying unique, permanent identifiers such as serial numbers, part numbers, batch codes, and manufacturer IDs directly onto components significantly enhances security. This is a powerful deterrent against the introduction of counterfeit or unapproved parts into the supply chain – a major safety risk in aviation. Precise, indelible coding makes it easier to identify genuine, certified parts, protecting passenger safety and the integrity of aircraft. In the event of a safety bulletin or potential part issue, precise coding allows for targeted, efficient identification and replacement of affected components, minimizing risk and ensuring fleet airworthiness.

- Optimized Inventory and Asset Management: Clear, consistent, and easily readable permanent marks facilitate accurate inventory tracking and management of high-value aviation assets and spare parts. This reduces errors in shipping, receiving, and stocking, minimizes discrepancies, helps manage the lifecycle of life-limited parts, and streamlines the entire supply chain process from manufacturer to operator to MRO.

- Increased Manufacturing and MRO Efficiency: Modern metal marking equipment, including precision numbering heads, are engineered for reliable operation, seamlessly integrating into manufacturing production lines and MRO workflows. Their durability and consistent performance minimize downtime associated with marking issues, boosting overall throughput and contributing to efficient part processing.

- Fortified Safety and Compliance Record: Professionally and permanently marked parts demonstrate a commitment to quality, reliability, and safety. Durable, clear codes provide verifiable proof of a part’s origin and history, essential for regulatory audits and accident investigations. This commitment enhances trust among regulators, operators, and the flying public.

Mark Your Aviation Parts for Permanent Identification

did you know?

no-cost marking of your sample part with expert recommendations

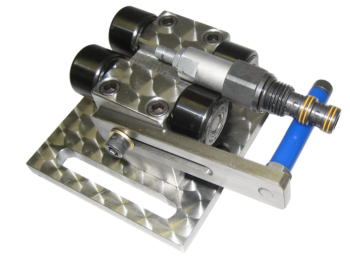

Numberall Custom Embossing Numbering Head. Permanent Marking of Metal Identification Tags.

Numberall: Your Partner for Precision Aviation Marking Solutions

For nearly a century, Numberall has specialized in developing robust, reliable marking solutions. We understand that the materials and operational environments in the aviation industry present unique and demanding challenges. That’s why we don’t just offer equipment; we provide customized marking solutions engineered to meet stringent aerospace specifications and your specific needs for durable, permanent aviation part identification.

Numberall marking solutions are designed to create clear, precise indentations on a variety of materials commonly found in aircraft parts requiring metal marking, including:

- Aluminum and Aluminum Alloys

- Titanium and Titanium Alloys

- Stainless Steel and other high-strength steels

- Inconel and other Nickel Alloys

- Durable Plastics and Composites (for surface marking where material integrity is maintained)

We pride ourselves on providing high-quality equipment that delivers precise, consistent, and durable marks, ensuring optimal performance and longevity in demanding aerospace environments. Our machines reliably stamp essential information, including part numbers, serial numbers, date of manufacture, batch codes, and other critical traceability data required by industry standards like UID/IUID.

Where Numberall Marks: Specific Aviation Applications

Numberall marking solutions are applicable to a wide range of aviation parts and components requiring durable identification for traceability:

- Engine Components: Marking on turbine blades, discs, vanes, shafts, and casings for critical lifecycle tracking and maintenance history.

- Structural Airframe Parts: Applying identification to ribs, spars, skins, bulkheads, and other structural elements.

- Landing Gear Components: Marking on struts, wheels, brakes, and actuators that experience high stress and environmental exposure.

- Fasteners: Indelible marking on critical bolts, nuts, rivets, and other fasteners where traceability to batch is essential.

- System Components: Identification on hydraulic components, actuators, valves, pumps, and electronic equipment housings.

- Data Plates: Manufacturing durable aircraft data plates containing essential information like model, serial number, and certification.

- Tools and Ground Support Equipment: Marking tools used in MRO for inventory control and calibration tracking.

These applications leverage the core strengths of Numberall marking solutions: creating permanent, durable indentations essential for traceability and compliance in an industry where parts must withstand extreme operational and environmental conditions.

Numberall Model 85P Numbering Head & Standard Type Holder, Stamp Aircraft ID Tags.

Looking for a solution to marking your aviation parts?

Discover custom metal marking solutions for your pet & livestock application. With our long history of innovation since 1930, we can meet any requirement. Request a Quote today!

Why Partner with Numberall for Aviation Marking?

Choosing the right marking partner is crucial for ensuring reliable, compliant traceability in the aviation industry. Here’s why businesses trust Numberall:

- Unmatched Experience: With over 90 years dedicated to marking technology, Numberall brings a depth of knowledge and expertise that is invaluable in meeting the unique demands of aerospace marking.

- Robust, Reliable Solutions: We specialize in durable metal marking solutions built to withstand the rigors of industrial environments and the lifespan of aircraft components, ensuring marks remain legible for decades.

- Customer-Centric Approach: Your specific aviation marking challenge is our priority. We provide personalized service and customized solutions designed to directly address your unique requirements for materials, mark content, and integration into your workflows.

- Proven Durability: Our core expertise lies in creating marks that last – a fundamental requirement universally critical in aviation.

By partnering with Numberall, businesses across the aviation sector – from manufacturers to MROs – can leverage the power of permanent metal marking to enhance safety, ensure regulatory compliance, streamline their processes, strengthen part security, and maintain the highest standards of aircraft part traceability.

Unmatched Benefits of Our Stamping Equipment

Customization

We offer tailored solutions to meet the unique marking requirements of your automotive parts.

Durability

Our stamping tools are designed to last, providing consistent performance even in demanding environments.

Precision

Ensure clear and accurate markings with our high-precision equipment.

Compliance

Meet industry standards and regulations with our reliable marking solutions.

Efficiency

Increase productivity with our easy-to-use and efficient stamping tools.

Support

Benefit from our exceptional customer service and technical support, ensuring your operations run smoothly.