July 21, 2025Marking Devices, Numbering & Lettering Presses

The Perfect Stamping Equipment – Numberall Model 40B

The Enduring Legacy of the Model 40B: Reliable Indent Marking for Modern Manufacturing

In an era dominated by high-tech solutions like laser marking, dot peen, and inkjet systems, Numberall Stamp & Tool Co. stands firm as a fourth-generation family business specializing in precision indent stamping equipment. Since 1930, we’ve delivered economical, reliable metal marking presses that prioritize simplicity, durability, and flexibility—without the need for software, extensive training, or frequent downtime. Our Model 40B Numbering and Lettering Press exemplifies this commitment, offering B2B customers across industries a cost-effective alternative for permanent traceability on parts, tags, and tools.

If you’re searching for “metal stamping press” or “indent marking equipment” to ensure compliance and product integrity without breaking the bank, read on to discover why the Model 40B has remained a bestseller for over 85 years—and how it can streamline your operations today.

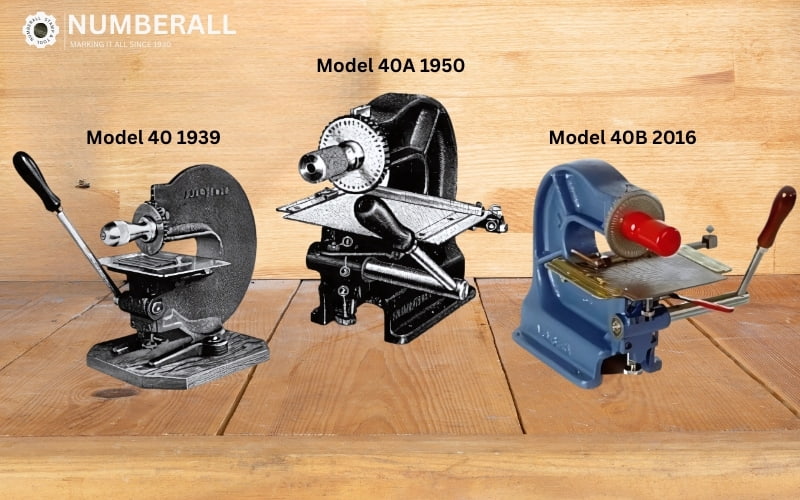

A Brief History of Innovation: From 1939 to Today

Invented in 1939, the original Model 40 set the standard for portable, hand-operated stamping presses. Its slender body design made it ideal for quick, on-the-go marking of flat items like nameplates and keys. Over the decades, we’ve refined it into the Model 40B, incorporating user-focused enhancements while preserving its core reliability.

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Recent Posts

Model 40B Key evolutions include:

- 1950s Redesign (Model 40A): A more robust body for improved stability during high-volume use.

- Modern Upgrades: Features like an adjustable table insert clamp, table stop clamp, table release lever, and dial tension block assembly for effortless operation and precise alignment.

These changes haven’t altered the fundamental mechanics— a simple dial and lever system powered by hand. Watch our video demonstration below to see the Model 40B in action, stamping clear, permanent marks with minimal effort.

As a family-owned business with over 90 years of experience, we’ve seen trends come and go. While competitors like Geo T. Schmidt, Pryor, Matthews Marking, and Mecco push advanced technologies, our niche in indent stamping delivers unmatched value: lower upfront costs, faster setup, and proven longevity. Many Model 40B units are still operational after 40+ years, thanks to their all-metal construction with no plastic or electronic components to fail.

did you know?

no-cost marking of your sample part with expert recommendations

Why Choose Indent Stamping Over Modern Alternatives?

In industries where traceability is non-negotiable—such as aerospace, automotive, manufacturing, agriculture, and mining—permanent marking is essential. But why opt for indent stamping when lasers and dot peen dominate searches?

- Economical Investment: Our presses start at a fraction of the cost of laser or dot peen systems, with no ongoing expenses for consumables, software licenses, or specialized training.

- Reliability and Low Downtime: Built from hardened steel, the Model 40B withstands harsh environments without electrical failures or calibration issues. Users report minimal maintenance, often handling it in-house with our readily available spare parts.

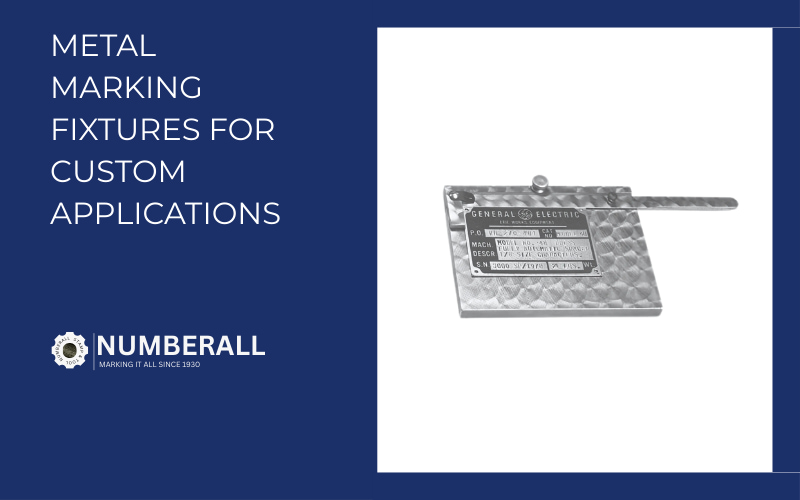

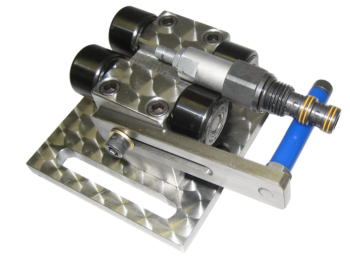

- Flexibility for Custom Needs: No software means instant adaptability. Customize with various nest sizes, strip holders, slides, tables, racks, or character dials to fit your specific application—whether marking serial numbers on machine parts, identification codes on tools, or batch info on brass tags.

- Precision Without Complexity: Achieve deep, legible indents on metals like steel, aluminum, and brass, ensuring marks survive extreme conditions for superior traceability.

- Eco-Friendly and User-Friendly: Hand-operated design reduces energy use and eliminates the need for ventilation systems required by lasers.

Unlike high-tech options from competitors, our equipment excels in scenarios where simplicity reigns—small production runs, on-site marking, or budget-conscious operations. We’ve engineered custom solutions for diverse industries, from veterinary tools to gun manufacturing, proving our presses’ versatility.

Ready to Experience the Model 40B Difference?

Many customers start with our no-cost sample marking service: Send us a part, and we’ll mark it with expert recommendations tailored to your needs. This touchpoint often leads to a seamless quoting process, where our sales engineers—with decades of combined experience—respond within 24 hours to craft a solution that exceeds expectations.

We also offer preventative maintenance guides, instructional videos, and lifetime support. Need modifications? We’ll engineer changes to accommodate shifts in your facility, ensuring your investment evolves with your business. Plus, with in-stock products and fast turnaround times, you get your equipment quicker than industry averages.

At Numberall, we’re not just selling presses—we’re partnering for your long-term success. If you’re tired of overcomplicated marking systems and want a reliable, economical alternative, request a quote today or contact our team for personalized advice.

Start With A Free Sample Marking

Send us your parts and we will provide a no obligation indenting of your part with a summary of recommendations.

Request A Quote

Our Sales Engineers have decades of expertise and are ready to respond, typically in 24 Hours.

Request A Catalog

Our product offering covers any industry related application needing a metal marking solution.

Looking for an economical custom solution to marking your equipment?

Discover custom metal marking solutions for your equipment. With our long history of innovation since 1930, we can meet any requirement. Making it easy to do business with us. Request a Quote today!

Recent Posts

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.