Struggling with durable marking? Numberall’s hot stamping, crafted in the USA since 1930, ensures permanent, vibrant marks on plastics and leather. Boost traceability and efficiency for manufacturers. Discover how!

The Difference Between Serializing and Simply Marking a Product

Recent Posts

The Ultimate Benchtop Press for Metal Stamping

Need reliable metal tag stamping? Numberall’s Model 40B, USA-made since 1930, delivers durable, traceable indent marks for makers, veterinarians, and locksmiths. Fast 24-hour shipping, simple operation. Discover now!

The Perfect Stamping Equipment – Numberall Model 40B

Need reliable indent marking? Numberall’s Model 40B, crafted in the USA since 1939, offers cost-effective, durable precision for tags and tools. Ensure traceability for makers and manufacturers. Explore now!

Elevate Your Products: Why Numberall Delivers Superior Metal Marking Solutions

Need durable metal marking? Numberall’s USA-made solutions since 1930 offer unmatched durability and custom options like numbering heads for precise traceability. Boost efficiency in manufacturing. Discover how!

The Difference Between Serializing and Simply Marking a Product

Enhance Your Product Tracking with Numberall's Quality Numbering Heads

What is Serialization?

In manufacturing, a serial number is a unique identification code assigned to each individual unit. Unique serial numbers are essential for inventory management, giving each product an identity that can be tracked from the factory to the consumer. As a process, serializing consists of consecutive character marking from unit to unit, such as P001, P002, P003, etc. If you need to mark a sequential code on each part, then serializing is likely the right marking method for you. On the other hand, if each part you are marking requires a completely new sequence, you likely do not need serializing equipment.

Which Product Works Best for Serializing?

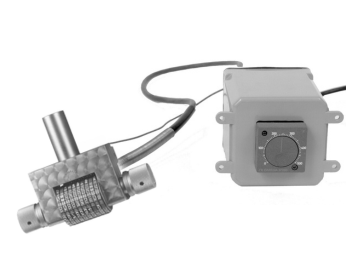

The Model 50P Automatic Numbering Head is ideal for serializing products with rapidly changing sequences, such as serial numbers, which change with each new part.

The Model 50P Automatic Numbering Head is ideal for serializing products with rapidly changing sequences, such as serial numbers, which change with each new part.

- During the marking sequence, the actuating arms are extended and retracted to advance the head to the next consecutive number with each new product, making it the best option for automatically serializing products in high volume.

- Additionally, the Model 50P is compatible with various optional equipment, including hot stamping equipment for marking plastics.

You can learn more about this specific model in our recent blog post, The History of Numberall’s Model 50P.

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Recent Posts

Other Options for Consecutive Marking

An elegant solution like the Model 70 can be used to mark series that change less frequently than after every mark, such as date codes that need to be swapped once a day.

- The Model 70 uniformly stamps repetitive sequences with consistent character alignment and depth of impression.

- This model stamps the same character sequence after each impression is made unless changed by the operator using a spanner wrench (included with product).

- The Model 70 is ideal for marking product codes, part numbers, or date codes.

- Its adaptability and versatility have made it popular with many industries. There is virtually no limit to the range of products that can be marked with the Model 70.

When the marked information changes more frequently, another convenient option is the Model 80P, which differs from the 70 in that it has a quick-change feature on the last wheel in the sequence.

When the marked information changes more frequently, another convenient option is the Model 80P, which differs from the 70 in that it has a quick-change feature on the last wheel in the sequence.

- Other wheels can also be changed using the spanner wrench.

- Depending on your product or date code, you may desire two or more wheels with the quick-change feature.

- We offer various models to accommodate this and can also create a custom numbering head based on the number of characters needed.

- For a more detailed breakdown of the differences in these numbering heads and their capabilities, view our non-automatic numbering head video.

did you know?

no-cost marking of your sample part with expert recommendations

Why Choose Numberall?

At Numberall, we pride ourselves on offering a wide range of high-quality marking equipment to meet your business’s needs. Here’s why you should choose Numberall for your serializing marking equipment:

- Experience and Expertise: With decades of industry experience, we have the knowledge to guide you to the best products for your specific needs.

- Quality and Durability: Our products are built to last, ensuring reliable performance for all your marking requirements.

- Customization Options: We offer a variety of models and can create custom numbering heads tailored to your exact specifications.

- Comprehensive Support: From initial consultation to after-sales support, we’re here to assist you every step of the way.

- Industry Recognition: Trusted by numerous industries for our consistent delivery of top-notch marking solutions.

When it comes to finding the best marking equipment to serialize your product, trust Numberall to provide the expertise and quality you need.

If you have any questions about our serializing marking equipment, or if you would like to request a quote, contact us at Numberall Stamp and Tool today.

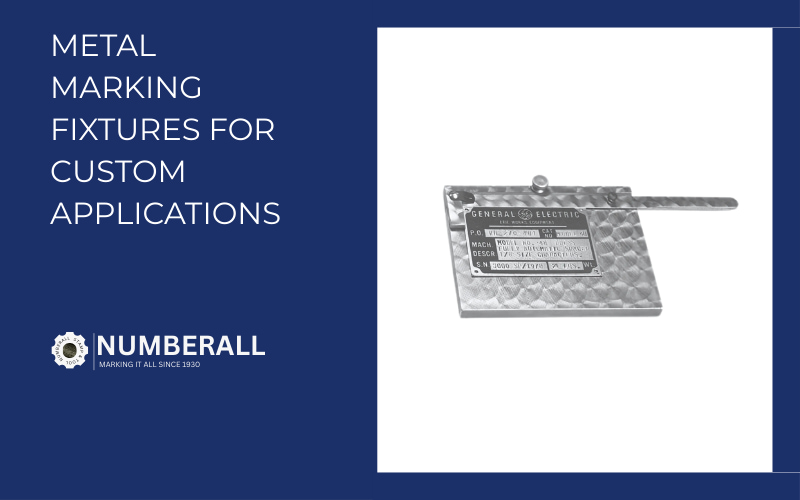

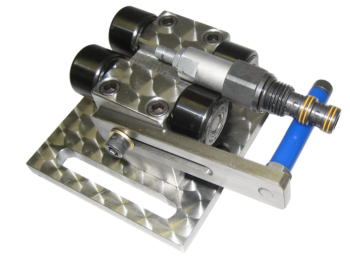

Looking for an economical custom solution to marking your equipment?

Discover custom metal marking solutions for your equipment. With our long history of innovation since 1930, we can meet any requirement. Making it easy to do business with us. Request a Quote today!

Recent Posts

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Join Numberall News

Get engineering expertise, new product spotlights, and helpful tips for durable parts marking.

Marking Solution?

Get a technical review and quote to meet your specifications.

- Standard or Custom Solutions

- Engineered for Durability

- 95+ Years of Expertise

Recent Posts

Hot Stamping: 3 Practical Applications For Industry

Struggling with durable marking? Numberall’s hot stamping, crafted in the USA since 1930, ensures permanent, vibrant marks on plastics and leather. Boost traceability and efficiency for manufacturers. Discover how!

The Ultimate Benchtop Press for Metal Stamping

Need reliable metal tag stamping? Numberall’s Model 40B, USA-made since 1930, delivers durable, traceable indent marks for makers, veterinarians, and locksmiths. Fast 24-hour shipping, simple operation. Discover now!

The Perfect Stamping Equipment – Numberall Model 40B

Need reliable indent marking? Numberall’s Model 40B, crafted in the USA since 1939, offers cost-effective, durable precision for tags and tools. Ensure traceability for makers and manufacturers. Explore now!

Elevate Your Products: Why Numberall Delivers Superior Metal Marking Solutions

Need durable metal marking? Numberall’s USA-made solutions since 1930 offer unmatched durability and custom options like numbering heads for precise traceability. Boost efficiency in manufacturing. Discover how!

Looking for an economical custom solution to marking your equipment?

Discover custom metal marking solutions for your equipment. With our long history of innovation since 1930, we can meet any requirement. Making it easy to do business with us. Request a Quote today!