March 4, 2025Benefits of Indent Marking, Marking Devices, Metal Marking

How to Determine Which Metal Marking Method You Should Use for Your Product

Choosing the Right Permanent Marking Method for Your Parts

Are you tasked with permanently marking products or components but unsure which method is right for your application? With a variety of marking technologies available, selecting the best one can feel overwhelming. The choice affects not only the quality of the mark but also your budget, production time, and long-term compliance.

As a leader in marking solutions since 1930, we understand these challenges. This guide will walk you through the most common permanent marking methods, exploring the pros and cons of each, to help you make an informed decision for your business.

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Recent Posts

1. Indent Marking (Mechanical Marking)

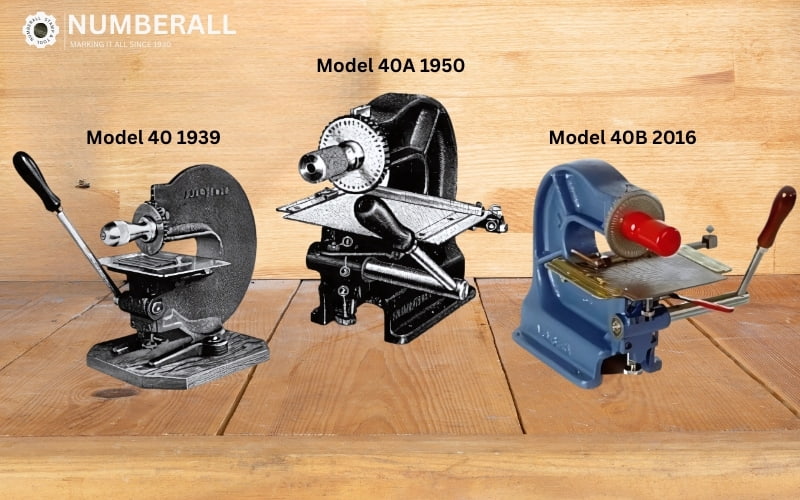

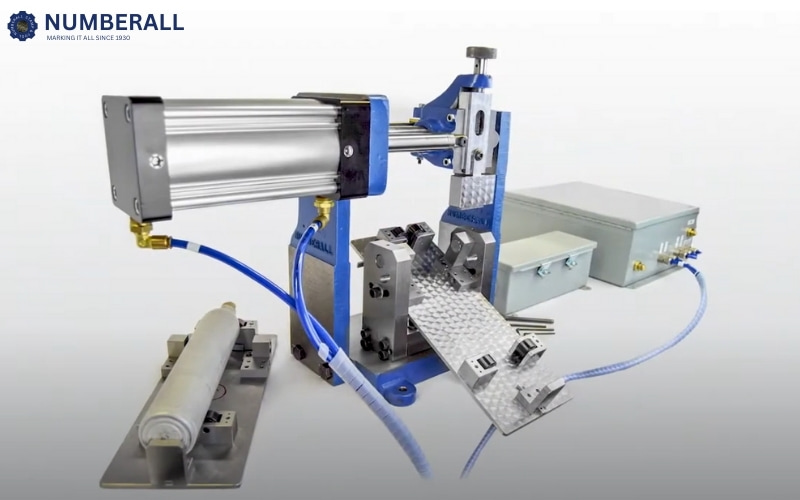

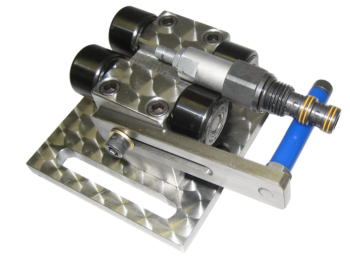

Indent marking is the process of physically displacing material to create a permanent impression. This can be done by a manual hammer, a machine press, or a roll marking machine.

Pros:

- True Permanence: The mark is physically embedded in the part and cannot be removed without destroying the material. This is crucial for industries with strict traceability or legal compliance requirements.

- Cost-Effective: Indent marking equipment often has a lower initial investment and minimal maintenance costs compared to laser or inkjet systems.

- Durability: The mark is resistant to harsh environments, solvents, paints, and sandblasting. It will not wear off over time.

- Ease of Use: Indent marking is straightforward to operate, requiring little specialized training.

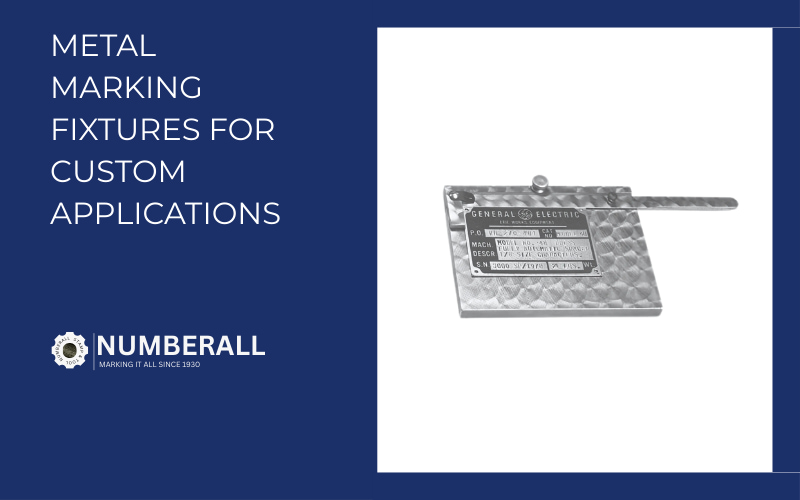

- Custom Solutions: Numberall offers standard and custom designs to fit unique part shapes and material requirements.

Cons:

- Destructive Marking: The force required to make the mark can put a strain on the part. For delicate components, this may cause deformation or damage if not handled correctly.

- Depth Limitations: The mark’s depth is limited by the material and the force of the machine.

2. Laser Marking

Laser marking uses a focused beam of light to alter the surface of a material, creating a permanent mark. It can be used for engraving, etching, or annealing (changing the color of the material).

Pros:

- High Precision and Speed: Laser marking is extremely fast and can create very detailed, high-resolution marks like logos or barcodes.

- Non-Contact: It is a non-destructive method that does not physically touch the part, making it ideal for delicate components.

Cons:

- High Cost: Laser systems have a significant upfront investment and often require expensive maintenance and specialized training for operators.

- Permanence Issues: The permanence of a laser mark can vary. A shallow laser etching may be removed by sandblasting or wear, making it insufficient for certain compliance needs.

- Downtime: Complex software and intricate components can lead to more frequent maintenance and potential downtime.

did you know?

no-cost marking of your sample part with expert recommendations

3. Chemical Etching

Chemical etching uses a stencil and a corrosive acid to “burn away” a shallow mark on a part.

Pros:

- Detailed Marks: It can create clear, precise marks on metals without high pressure.

- Non-Destructive: The process is non-mechanical and does not deform the part.

Cons:

- Safety Concerns: The use of caustic acids requires extreme caution, specialized handling, and proper ventilation, increasing operational and safety costs.

- Consumable Costs: The stencils and screens used will wear out over time and require frequent, costly replacement.

- Lack of Permanence: Like some laser markings, chemical etching creates a shallow mark that can be removed with solvents, sandblasting, or coating.

4. Ink Marking

Inkjet marking utilizes a printer to spray a stream of ink onto a product.

Pros:

- High Speed: This is a very fast method for marking a product, often used on a moving conveyor belt.

- Variety of Surfaces: It can be used on a wide range of materials.

Cons:

- Not Permanent: Ink can be easily removed by solvents, abrasion, or even just wear over time. It is not suitable for applications requiring true permanence.

- Messy and Inconsistent: The process can be messy, and the mark may be inconsistent depending on the surface and environment.

- Downtime: Inkjet printers require regular maintenance and consumable ink cartridges, leading to higher operating costs and potential production halts.

Real-World Custom Solutions for Your Industry

Our expertise goes beyond our primary product line. We specialize in engineering innovative solutions for a wide range of industries that require permanent marking. These examples highlight our ability to solve unique challenges with custom equipment and trusted, standard solutions.

Food & Beverage

- The Problem: A major beverage company needed to permanently mark their SodaStream CO2 aluminum gas cylinders without deforming the hollow parts.

- The Solution: We designed and built a custom roll marking press that could apply a precise, permanent mark with minimal force, ensuring compliance and product integrity.

- The Result: The company was able to efficiently mark their products with a custom solution that met their quality standards and production volume.

Aviation

- The Problem: During World War II, the military needed a partner they could trust to engrave the sight plates for the top-secret Norden bombsight, a task that demanded unmatched precision and reliability.

- The Solution: Numberall was entrusted with this critical project, utilizing our expertise to engrave the sight plates with the highest level of accuracy and craftsmanship.

- The Result: We successfully delivered mission-critical components, establishing a legacy of trust and precision that has defined our work for generations.

Security Seals

- The Problem: TydenBrooks, a leader in the security industry, required a highly permanent, tamper-resistant marking solution for various products like lobster trap tags and cable seals.

- The Solution: They chose to use Numberall’s standard equipment with our precise numbering heads, which are engineered to deliver deep, durable marks.

- The Result: Our standard products not only met but exceeded the industry’s strict permanence requirements, proving that Numberall’s inherent quality provides reliable, tamper-resistant solutions.

Why Numberall Is Your Best Choice for Permanent Marking

While other methods may be suitable for certain applications, Numberall’s indent marking solutions offer a distinct advantage for businesses seeking reliability, permanence, and a strong return on investment.

- Unrivaled Permanence: For critical applications, nothing beats the permanent, physical mark of our indenting machines.

- Economical and Reliable: Our equipment is built for durability, minimizing the high costs of consumables, maintenance, and training associated with laser and inkjet systems.

- Innovative Engineering: With a legacy dating back to 1930, our engineering team drives innovative solutions. We offer standard and custom designs with quick lead times, ensuring you get the perfect machine for your needs.

- Industry Expertise: We don’t just sell machines; we partner with you to find the right solution. Our expertise is backed by a portfolio of successful projects.

If you’re new to permanent marking and need guidance to find the best method for your product, our team of experts is ready to help. Our machines are designed to meet your needs and our reputation is built on trust and reliability.

Looking for an economical custom solution to marking your equipment?

Discover custom metal marking solutions for your equipment. With our long history of innovation since 1930, we can meet any requirement. Making it easy to do business with us. Request a Quote today!

Recent Posts

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.