April 22, 2025Custom Applications, Metal Marking, Numbering Heads

Old Numbering Machines? Our 11 Division Wheel Can Fix Those, Too

Modify Metal Marking Equipment: Numberall’s 11 Division Wheel Solutions

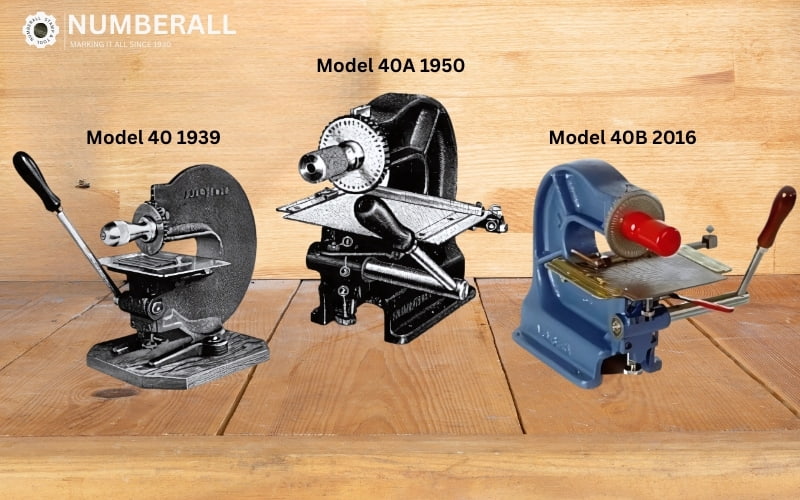

Retooling outdated metal marking equipment can cost thousands and delay production. Numberall Stamp and Tool Co., a 4th-generation family business since 1930, solved this for a manufacturer with a custom solution. We specialize in custom indenting stamping, collaborating with customers to modify most marking equipment for their needs. Unlike others chasing laser or inkjet trends, our expertise delivers precise, permanent traceability for industries like beverage, automotive, and manufacturing, with machines lasting over 40 years.

Solving Legacy Equipment Challenges

Older numbering machines with unique features like zero suppression are costly to replace due to retooling. Our 95-year engineering expertise lets us work closely with you, tailoring modifications for most equipment to save time, reduce costs, and keep your production running smoothly.

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Recent Posts

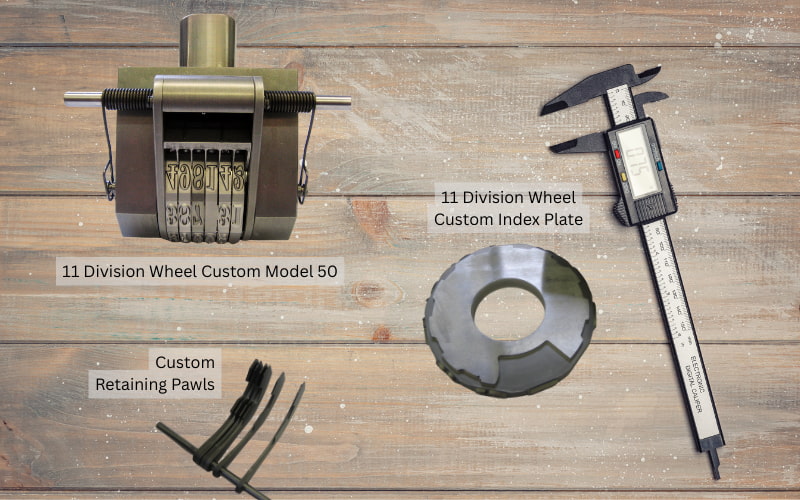

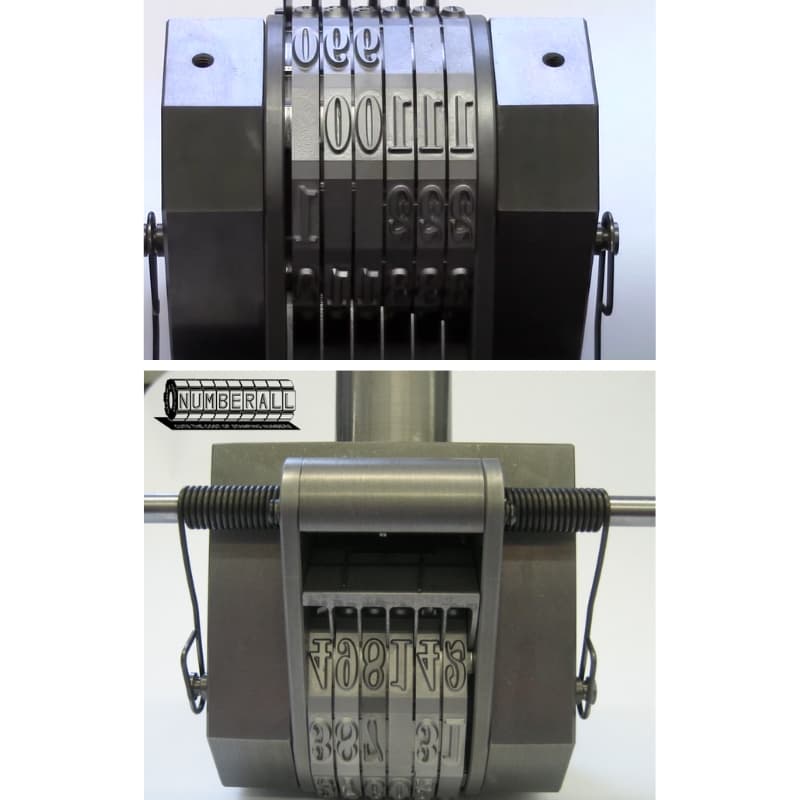

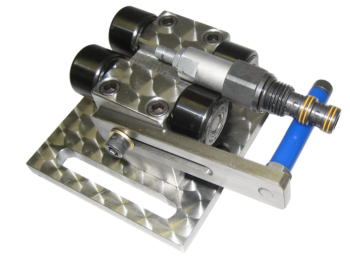

Engineering the 11 Division Wheel

When a customer needed to modernize legacy numbering machines, Numberall’s engineers re-designed the 11 Division Wheel. This custom solution delivers large characters on smaller wheel diameters with zero suppression, tailored to your setup. A re-engineered pawl ensures precise alignment. Requiring no software or training, our economical, flexible design minimizes downtime.

Key Benefits of Our Approach:

- Modify most marking equipment to meet your specific needs.

- Save thousands by avoiding retooling with tailored solutions.

- Deliver precise, durable impressions with zero suppression.

Request More Information: Let our experts customize a solution for your equipment. Contact Us to learn about the 11 Division Wheel!

Real-World Success

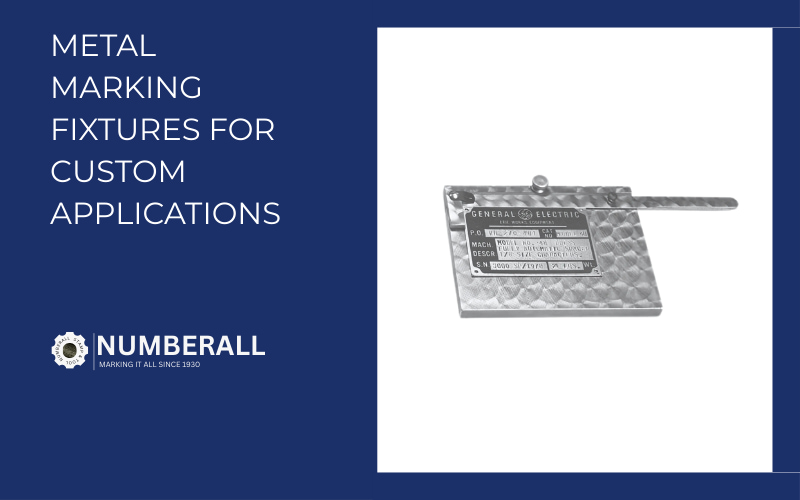

SodaStream® needed durable impressions for CO2 gas bottle traceability. Numberall’s custom roll marking solution reduced gray market issues and ensured compliance with OSHA 29 CFR 1910.101. [Explore more case studies by industry]

did you know?

no-cost marking of your sample part with expert recommendations

Why Numberall Excels

- Customer-First Expertise: Custom indenting solutions since 1930, tailored to your needs.

- Fast Turnaround: Quotes in 24 hours, outpacing industry standards.

- Cost & Reliability: Economical machines with less downtime, no software/training needed.

- Flexible Precision: Modifications for most applications, delivering precise marks.

- Lasting Durability: Machines built to last decades, with maintenance guides and videos.

Don’t let outdated equipment slow you down. Trust Numberall to simplify your marking needs with custom solutions.

Request a free quote or sample markings today. Visit numberall.com for case studies, videos, or in-stock products.

Looking for an economical custom solution to marking your equipment?

Discover custom metal marking solutions for your equipment. With our long history of innovation since 1930, we can meet any requirement. Making it easy to do business with us. Request a Quote today!

Recent Posts

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.