The History of Numberall’s Model 50P

Numberall produced the first Model 50P in the fall of 1935, after many months of planning and engineering. The goal was to provide customers with a machine that could precisely and efficiently mark a number of materials consecutively with minimal effort from the operator.

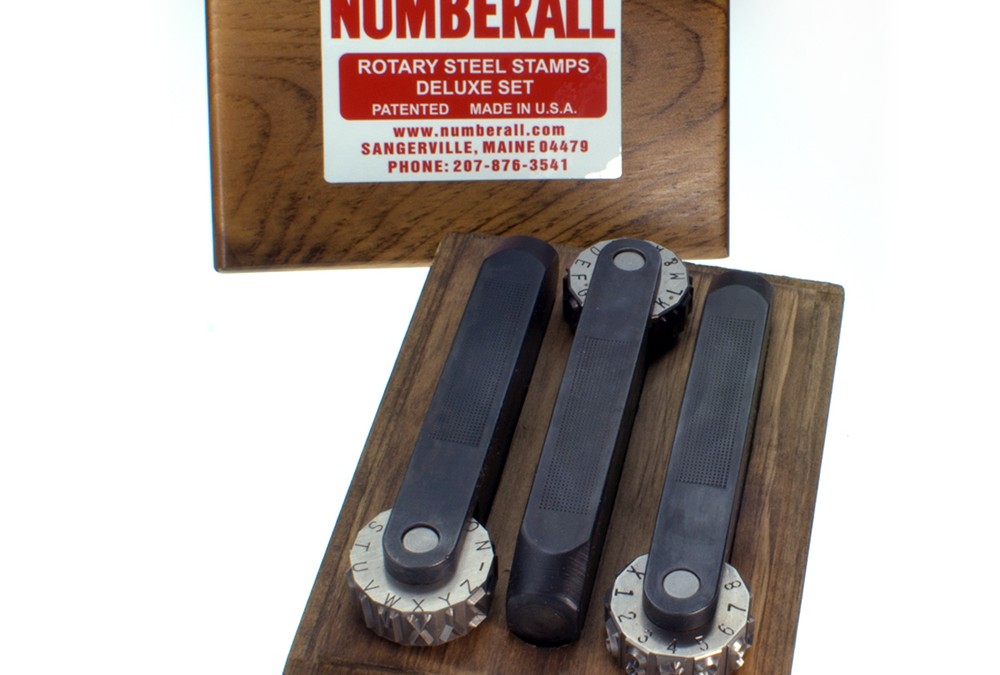

Product Spotlight: Rotary Stamps

Product Spotlight: Rotary Stamps Why Numberall’s Rotary Stamps Are the Smart Choice for Durable Metal Marking Since 1930, Numberall Stamp & Tool Co., a fourth-generation family business, has led the metal indent stamping industry, offering cost-effective, reliable...

Extra Large Characters

Extra Large Characters Numberall's Expertise in Custom Non-Automatic Large Character Marking Heads At Numberall, we specialize in crafting non-automatic large character marking heads tailored to meet the specific needs of various applications. Our experience and...

Custom Product Spotlight: Numberall’s Concrete Stamp

At Numberall Stamp and Tool, we take pride in our ability to offer high-quality stamping equipment. These stamping tools can be used to mark a variety of materials across several different industries. While we have a wide range of products that we offer, we also can create high-quality custom marking tools at our customer’s request.

Numberall Staff Spotlight: John French

For nearly 90 years, Numberall has provided custom stamping tools for clients around the globe. We attribute this longevity to our high-quality marking products and also to the hard work and commitment of our employees — some of whom have been working at Numberall for over three decades. Topping the list is John French, who is going on almost five full decades of employment with Numberall.