May 28, 2025Automatic, Custom Applications, Numbering Heads

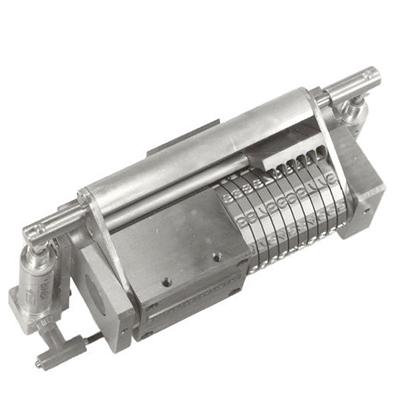

Custom Model 50P Automatic Numbering Machine

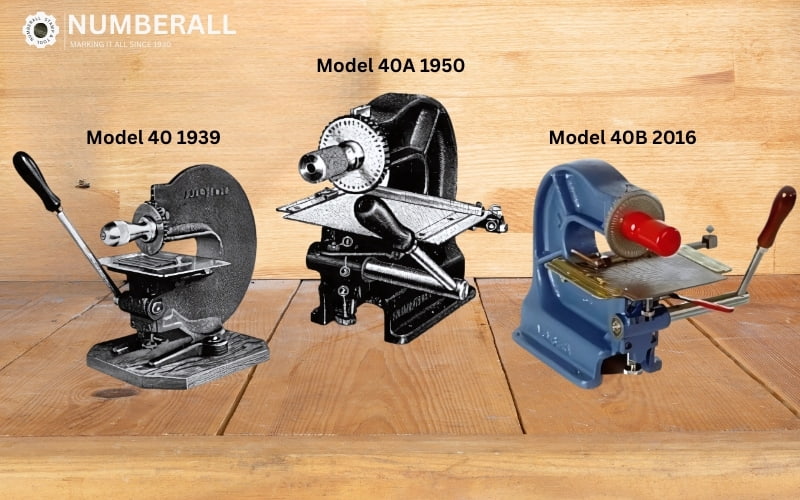

When Space is Tight: Numberall's Custom Model 50 Solves a Big Challenge with Thin Wheels At Numberall

We thrive on a challenge. While our standard marking equipment is renowned for its durability and precision, sometimes a customer’s unique application demands a solution that’s anything but standard. We recently tackled one such intricate project, demonstrating our nearly century of expertise in custom design.

The Challenge: Big Characters in a Small Space

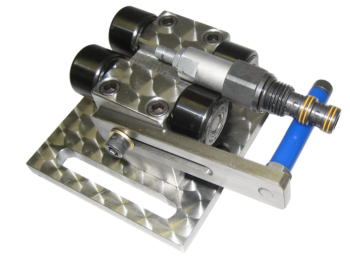

A customer approached us with a critical need for a Model 50 automatic numbering head. Their product’s stamping area presented a significant limitation: incredibly tight clearance. They needed to mark their product with a character size larger than what standard wheels could offer, yet the overall dimensions of the marking head had to be drastically reduced to fit within their confined stamping space. This seemed like a contradiction, but it was exactly the kind of puzzle Numberall loves to solve.

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Recent Posts

did you know?

no-cost marking of your sample part with expert recommendations

The Numberall Solution: Precision Engineering in Record Time

Our engineering team immediately went to work, leveraging Numberall’s 95 years of experience in metal marking innovation. Here’s how we achieved the impossible:

- Modified Frame with Milled Clearance: The core of the solution involved a significant modification to the Model 50’s robust frame. We precisely milled away material to create crucial clearance, ensuring the head would fit perfectly into the customer’s limited product stamping area.

- Custom Thinner Springs: To further accommodate the reduced space, we engineered and integrated custom springs that provided the necessary tension while maintaining the required clearance within the redesigned frame.

- Custom Engraved Thinner Wheels with Large Characters: This was arguably the most innovative part. We designed and manufactured custom engraved wheels that were significantly thinner than our standard wheels. Despite their reduced thickness, we maintained the customer’s desired larger character size, ensuring clear and legible impressions. This required meticulous precision in the engraving process to ensure durability and readability.

The result? A truly unique Model 50 that perfectly fit the customer’s specifications. What’s more, our dedicated team completed this complex custom build in less than two weeks, delivering it on time and exceeding our customer’s expectations. This rapid turnaround highlights our commitment to efficiency and customer satisfaction, even on the most demanding projects.

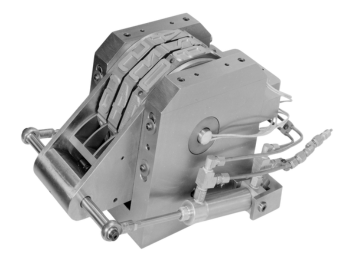

Other Custom Designs and Applications We’ve Developed

The custom Model 50 described above is just one example of Numberall’s ability to create specialized marking solutions. Our portfolio of unique designs includes:

- King Size Model 50 with Hot Stamping Capabilities: This robust machine was specifically engineered to hot stamp cattle tags in the pet and livestock industry, providing durable, high-visibility markings.

- Custom Model 50P with an Extended Leg Type Holder: Designed for the packaging industry, this model allows for accurately stamping complex product codes on various packaging materials, reaching difficult-to-access areas.

- Custom Model 50 with Concave Engraved Wheels and Type Holder: For the automotive OEM industry, we developed this specialized Model 50 to precisely stamp curved automotive parts, ensuring consistent marking on irregular surfaces.

- Model 70P with Extended Frame Leg & Logo Die Pocket: Allowing for custom spacing between numbering and a distinct logo, perfect for specific product branding requirements.

- Model 70 with Multiple Wheel Groups: Creating custom spacing and extra support for marking sequences requiring numerous wheels or specific character clusters.

No matter how intricate your marking challenge, Numberall has the experience, the engineering prowess, and the commitment to deliver a solution that not only meets but exceeds your expectations.

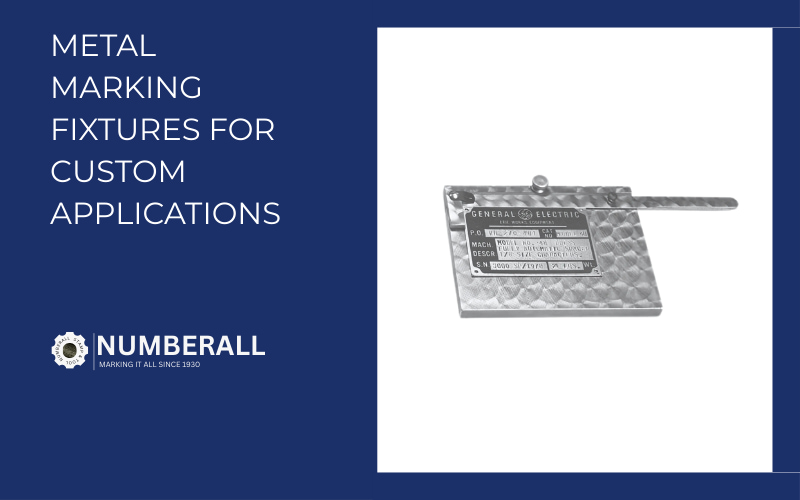

Looking for an economical custom solution to marking your equipment?

Discover custom metal marking solutions for your equipment. With our long history of innovation since 1930, we can meet any requirement. Making it easy to do business with us. Request a Quote today!

The Benefits of Partnering with Numberall for Custom Designs

Choosing Numberall for your custom marking solutions offers distinct advantages:

- 95 Years of Expertise: Our rich history and deep knowledge in metal marking mean we’ve likely encountered (and solved) challenges similar to yours, giving us an unparalleled foundation for innovation.

- True Customization: We don’t just offer minor tweaks; we re-engineer and build from the ground up to meet your exact specifications, no matter how unique.

- Rapid Prototyping & Delivery: Our in-house design and manufacturing capabilities allow for quick turnarounds, getting your custom solution into production faster.

- Quality & Durability: Every custom machine benefits from the same robust construction and precision engineering that goes into our standard, Made-in-the-USA equipment, ensuring long-lasting performance.

- Problem-Solving Focus: We view complex requirements not as obstacles, but as opportunities to apply our ingenuity and deliver superior results.

Recent Posts

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.