June 6, 2025Custom Applications, Custom Steel Stamps

Ordering Custom Steel Stamps from Numberall

Precision Manufacturing: Your Definitive Guide to Ordering Custom Steel Stamps from Numberall

In manufacturing and product identification, the ability to leave an indelible, high-quality mark is fundamental. At Numberall Stamp & Tool Co., we’ve been the trusted manufacturer of custom steel stamps for generations, delivering the tools that create lasting impressions on critical components and finished products.

What distinguishes a Numberall custom steel stamp? It’s our customer first pursuit of excellence in material and craftsmanship.

- We begin with a proprietary selection of premium tool steel, chosen for its inherent strength and wear resistance.

- Each stamp then undergoes a meticulously controlled, multi-stage heat treatment process, transforming it into a high-impact instrument that defies chipping and degradation even under relentless industrial use.

- The crisp characters are expertly engraved, ensuring every impression is crisp, clean, and perfectly defined.

- Our commitment to durability and precision means your Numberall stamp is an investment designed for exceptional longevity and consistent performance.

Whether your application demands a simple date code, intricate logo, or complex serial number, a custom steel stamp offers unmatched permanence and clarity. This guide is designed to empower you with the knowledge to specify your ideal custom steel stamp, ensuring it meets your exact requirements and delivers flawless results.

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Recent Posts

The Numberall Promise: Craftsmanship, Durability, Innovation

Our legacy in the marking industry is built on core principles that distinguish Numberall:

- Expert Engineering: We don’t offer off-the-shelf solutions for custom needs. Every stamp is a bespoke creation, meticulously engineered to align with your unique design, material, and operational parameters.

- Superior Material Science: Our deep understanding of metallurgy allows us to select and treat steels that deliver maximum hardness, impact resistance, and tool life, ensuring your investment truly endures.

- Unwavering Quality: From the initial design consultation to the final precision engraving, every step in our process is governed by stringent quality controls, guaranteeing a flawless marking tool.

- Comprehensive Application Expertise: Leverage our decades of experience. We provide insightful guidance to ensure the right stamp type, character style, and dimensions are chosen for your specific product and production environment.

did you know?

no-cost marking of your sample part with expert recommendations

Essential Specifications for Your Custom Steel Stamp Order

To engrave your custom steel stamps, we require a detailed understanding of your marking needs. Please consider the following key areas:

1. Method of Application: Hand-Strike, Press-Driven, or Integrated Insert?

The intended use of your stamp dictates its fundamental design and physical structure.

- Custom Hand Stamps: Engineered for direct, manual striking with a hammer. These stamps feature optimized shank dimensions and a robust build designed to absorb and distribute percussive force effectively, ensuring maximum durability under repeated blows.

- Custom Press Stamps: Fabricated for consistent, high-force application within mechanical presses. These are specifically designed for compatibility with industrial marking presses, including Numberall’s own Models 136,137, 131, and 133, ensuring seamless integration and reliable performance in automated or semi-automated systems.

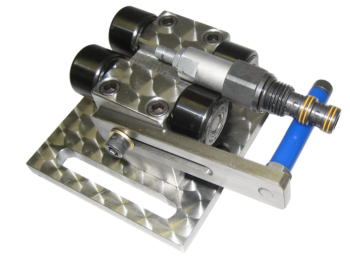

- Custom Insert Stamps: Designed to integrate into specialized holders, jigs, or fixtures. This category includes our custom logo insert stamps, precisely manufactured to fit Numberall’s Model 23P or Model 23H holders, or to exact customer-supplied holder specifications, providing flexibility for diverse setups.

2. Design Visuals: Artwork for Logos, Trademarks, or Special Graphics

For any custom logo stamps, trademark stamps, or intricate designs, high-fidelity artwork is critical. This ensures the accurate reproduction of your visual identity onto the stamp face.

- Preferred File Formats: We highly recommend vector-based files such as .eps, .pdf, .ai, .dxf, or .dwg. These formats allow for infinite scalability without any loss of detail or resolution, ensuring a sharp, clean engraving.

- Alternative Formats: High-resolution raster images may be acceptable, but please consult our design team to discuss specific file types and potential artwork preparation requirements.

3. Mark Dimensions: Overall Design Size and Individual Character Height

- Provide the precise desired dimensions for your finished mark. This includes the overall height and width of your design, as well as the specific height of any individual characters or numbers.

- Accurate sizing is paramount for ensuring the mark fits optimally on your product and remains legible.

4. Impression Style: Selecting the Character Face and Profile

The profile of the engraved character directly influences the visual quality and suitability of the mark for various materials.

- Sharp Face: These characters feature a finely angled, pointed apex, designed to penetrate materials cleanly. They produce a deep, crisp, and well-defined impression, ideal for harder metals where a pronounced mark is desired.

- Flat Face: With a broad, flat contact surface, these characters create a wider, shallower impression. They are typically favored for marking softer materials like aluminum, brass, or plastics, and are also ideal for applications involving hot stamping with foil.

- Specialized Profiles: Depending on your unique material characteristics or desired marking effect (e.g., low-stress, aesthetic preference), we can discuss other custom character profiles tailored to your needs.

5. Product Surface Dimensions: Available Marking Area

- To ensure a perfect impression every time, it’s essential to understand the exact space available on your product for the mark.

- Provide the precise length and width of the clear, unobstructed area where the stamp will be applied. This allows us to optimize the stamp design for fit and alignment.

6. Surface Geometry: Contour of the Material Being Stamped

The shape of the surface receiving the impression significantly affects the stamp’s design requirements.

- Flat Surfaces: For planar components, a standard flat stamp face is appropriate.

- Curved Surfaces: For cylindrical, spherical, or other curved parts, the stamp’s engraving may need to be custom-contoured (e.g., radiused or angled) to ensure uniform contact and a consistent, undistorted impression across the entire mark.

- Complex Geometries: For highly irregular or multi-faceted surfaces, our engineering team can collaborate with you to develop specialized stamp solutions.

7. Stamp Body Specifications: Blank Style and Physical Dimensions

- The “blank” refers to the un-engraved steel body of the stamp. Specifying its style and exact dimensions is critical for ensuring mechanical compatibility with your existing press, fixture, or holder.

- Our comprehensive drawings for configurations are available to guide you in providing precise measurements for an accurate quote and a perfectly integrated tool.

Begin Your Custom Marking Project with Numberall

At Numberall, we don’t just manufacture steel stamps; we deliver precision marking solutions backed by generations of expertise. Our dedicated team is ready to assist you in designing and producing the ultimate custom steel stamp for your operations.

Ready to elevate your product marking? We invite you to contact our expert customer service team today or submit a detailed request for a personalized quote. Let’s forge a lasting mark together.

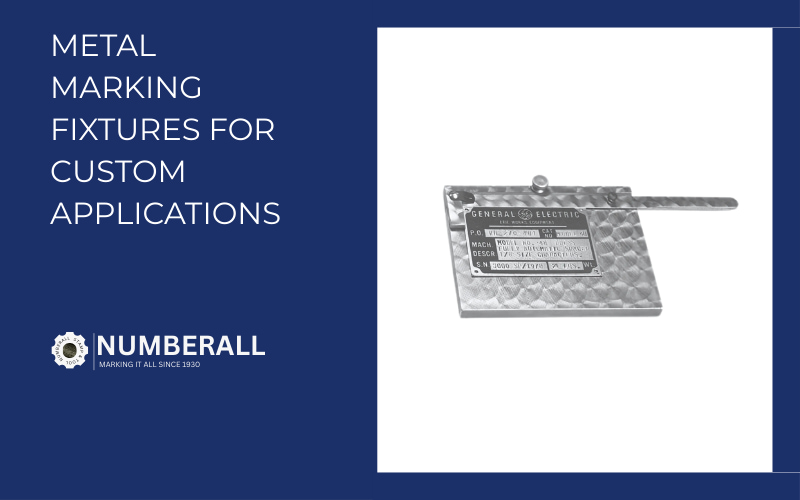

Looking for an economical custom solution to marking your equipment?

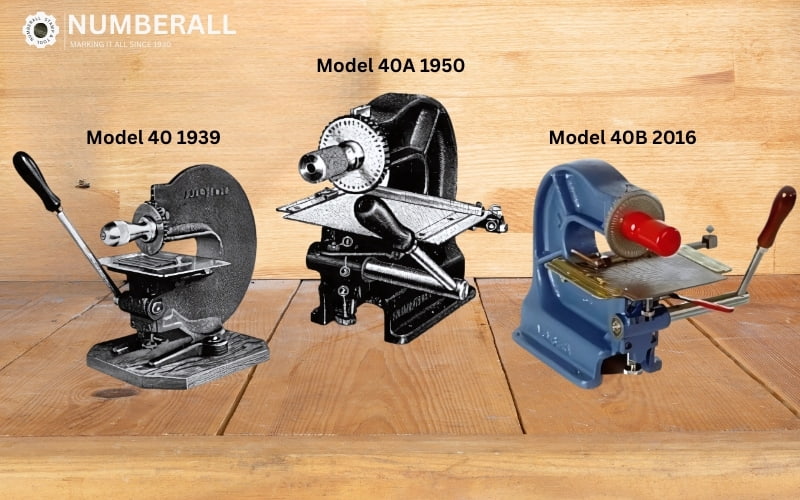

Discover custom metal marking solutions for your equipment. With our long history of innovation since 1930, we can meet any requirement. Making it easy to do business with us. Request a Quote today!

Recent Posts

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.