March 3, 2025Benefits of Indent Marking, Metal Marking, Stamping Force Calculation

Find the Right Marking Device with Numberall’s Comprehensive FAQ Guide

How Much Force Do You Need for Metal Stamping? Try Our Calculator

Since 1930, Numberall has been a trusted name in industrial marking, delivering reliable, mechanical indenting solutions as a fourth-generation family-owned business. Our new Stamping Force & Equipment Selector simplifies choosing the right tool for your marking needs—whether you’re stamping dog tags, serial numbers, or heavy-duty industrial parts. This free, interactive tool estimates the force required and recommends the best press and marking solution from our time-tested lineup.

Why Choose Numberall for Metal Stamping?

Unlike modern alternatives like dot peen, inkjet, or laser marking, Numberall specializes in traditional indenting stamping equipment. Our mechanical solutions are:

- Economical: Lower upfront and maintenance costs compared to high-tech systems.

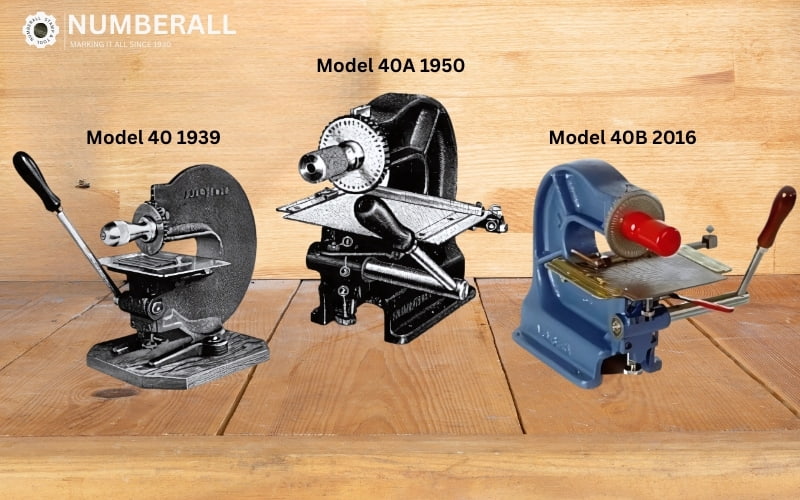

- Durable: Machines built to last 40+ years with minimal downtime.

- Flexible: Custom solutions for diverse materials (metal, plastic, wood, leather) and industries (aerospace, automotive, manufacturing, medical).

- User-Friendly: No software or extensive training required.

- Precision-Engineered: Consistent, high-quality marks for traceability and part identification.

Our sales engineers, with decades of experience, provide tailored solutions, preventative maintenance, and modifications to adapt to your facility’s needs. While our custom solutions may require longer lead times due to their specialized nature, we strive to deliver quotes in 24 hours, lifetime support, and in-stock products for faster delivery when available.

Request a Free Quote Today to start your project.

Found this helpful? Share it with your network!

Share on LinkedIn | Share on Twitter/X | Share on Facebook

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Recent Posts

Introducing Our Stamping Force & Equipment Selector

Our new Stamping Force & Equipment Selector is a free interactive tool designed to help you estimate the stamping force needed for your application and recommend compatible presses and marking tools. Built on industry-standard engineering formulas, it considers factors like material type, character size, depth, number of characters, thickness, and safety margins.

Try the Calculator Now to get started (requires email for detailed results and recommendations).

This tool serves as a valuable starting point, enabling you to explore options and initiate discussions with our team for custom configurations.

Why Stamping Force Matters

The force required for metal stamping depends on:

• Material: Aluminum, brass, steel, plastic, wood, or leather.

• Character Size and Depth: Larger or deeper marks need more force.

• Number of Characters: Multi-character setups increase force requirements.

• Material Thickness: Thicker parts demand higher force.

• Safety Factor: Ensures consistent, legible marks without tool damage.

Too little force risks faint marks; too much can damage tools or presses. Use our selector to take the guesswork out of equipment selection.

Choosing the Right Numberall Solution

Our calculator is a starting point to guide your equipment selection. Here’s how to choose the best tool for your needs:

Which Press Should I Use?

Force Range Recommended Press Best For

< 4,000 lbf Model 136 / 136A Bench Press Lightweight tags, keys, nameplates

4,000–8,000 lbf Model 137 Motorized Bench Press Medium-duty marking, mild steel

8,000–15,000 lbf Model 131 / 131A Air-Operated High-volume, precision parts

> 15,000 lbf Model 133 Heavy-Duty Motorized Deep marks, heavy industrial parts

Numberall Stamping Force Calculator

Instantly discover the exact Numberall press and tooling you need – Made in USA since 1930

Professional Engineering Estimate

These results are calculated from 95 years of Numberall’s proprietary stamping data and provide an accurate starting point for your application.

Final system specifications may be refined based on material samples, part geometry, and production requirements.

Contact our engineers for a free, no-obligation application review and firm quotation.

Numberall Stamp & Tool Co., Inc. • Proudly Made in USA since 1930

Sangerville, Maine • 800-685-3072 • sales@numberall.com

did you know?

no-cost marking of your sample part with expert recommendations

Real-World Applications

Numberall’s equipment powers traceability across industries:

• Food and Beverage: Serial marking on round parts with Model 301 Roll Marking Press for SodaStream.

• Electronics: Precision part marking with Model 131A + Model 23.

• Agriculture: Hot stamping cattle tags on plastic with Model 250P + Model 223P.

• Custom Branding: Marking leather or wood with Model 270P or 285P.

• Identification Tags: Efficient stamping of dog tags, keys, mailbox labels, and security badges with Model 40B numbering and lettering press.

Download Our Industry Case Studies to see how we solve marking challenges.

Choosing the Right Numberall Solution

While many marking technologies exist, our indent marking solutions offer a distinct advantage in terms of permanence, durability, and long-term value.

- The Mark of Permanence: A Lifetime You Can Trust An indent mark is a physical deformation of the material itself. Unlike laser, ink, or chemical etching that alters the surface, our marks are a part of the part. They cannot be worn off, scraped away, or faded by UV light, making them the ultimate solution for traceability and branding that lasts as long as your product.

- The Power of Simplicity: Built for a Lifetime of Use Our robust, mechanical marking systems are engineered for industrial environments. They are simple, reliable, and don’t rely on complex electronics, software, or expensive consumables. We are so confident in the quality of our equipment that we offer a lifetime warranty, a testament to its durability and a peace of mind that newer, more complicated technologies often can’t provide.

- The Economic Advantage: Long-Term Value, Not Short-Term Cost An investment in a Numberall machine is a one-time investment in a permanent solution. Without the need for expensive consumables like ink or gases, and minimal maintenance, our products offer a superior total cost of ownership. Your marking solution will be up and running for years, providing consistent, reliable results without unexpected recurring expenses.

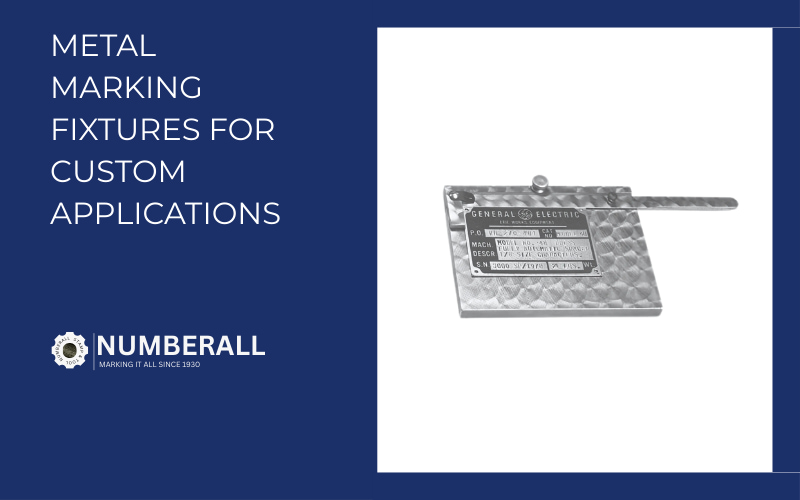

Real-World Solutions: Case Studies by Industry

To give you a better idea of how our solutions work in practice, here are a few examples of how we’ve helped businesses in different industries create permanent marks.

Agriculture

- Problem: A manufacturer of farming equipment needed to mark serial numbers and part codes on steel components that would be exposed to harsh outdoor conditions, dirt, and daily abrasion. The marks had to be deep and permanent for traceability and warranty purposes.

- Solution: We provided a custom air-operated bench press with a heavy-duty numbering head. This system delivered the consistent, high force needed to create a clear, permanent indent into the thick steel parts, even on a high-volume production line.

- Result: The customer achieved a reliable, permanent marking process that ensured every part was traceable for its entire lifespan, regardless of environmental conditions.

Livestock & Pets

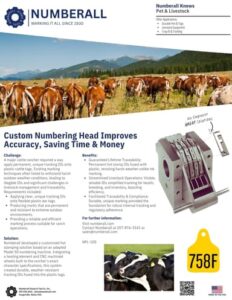

- Problem: A cattle rancher needed a reliable and permanent way to mark plastic ear tags for animal identification. The marks had to be highly visible and durable enough to withstand a harsh, outdoor environment.

- Solution: We developed a custom, king-size Model 50 automatic numbering head with hot stamping capabilities. We machined and engraved the oversized wheels to create a perfect, permanent mark on the plastic tags. Our in-house team completed the project and delivered the custom solution in just two weeks.

- Result: The cattle rancher’s livestock operations were improved with a reliable and permanently visible tag ID, ensuring every animal could be tracked easily and accurately for its entire life.

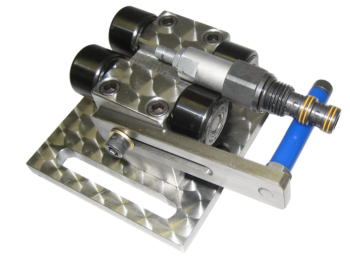

Electronic Component Industry

- Problem: A manufacturer of delicate PCB boards needed to permanently mark serial numbers and date codes without stressing the components and causing damage.

- Solution: We engineered a custom solution using our Model 50 automatic numbering head with specially designed round face characters. This allowed us to create a precise indent mark with minimal stress on the delicate part, even with our indenting process.

- Result: The customer achieved faster throughput and enhanced product security. The permanent, low-stress marking solution helped to reduce gray market counterfeiting and improve product traceability.

Looking for an economical custom solution to marking your equipment?

Discover custom metal marking solutions for your equipment. With our long history of innovation since 1930, we can meet any requirement. Making it easy to do business with us. Request a Quote today!

Recent Posts

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.