May 25, 2025Benefits of Indent Marking, Ink Marking, Marking Devices

The Pros and Cons of Ink Marking Your Products

Why Numberall Stamp & Tool Co. Prioritizes Permanent Marking A Guide to Choosing the Right Metal Marking Equipment

When you’re looking for a way to mark your products, you’ll find a variety of methods available, from hot stamping and ink marking to micro-percussion and dot marking. While each has its place, some are more effective for achieving long-term, reliable results. As a company with a strong commitment to innovation, we believe in providing solutions that meet both today’s needs and tomorrow’s.

We often discuss these marking methods with customers at industry events like EASTEC and other manufacturing trade shows, where we showcase our latest metal marking equipment. A common topic of conversation is the difference between temporary and permanent marking.

The Problem with Ink Marking

During a recent EASTEC event, we received many questions about ink marking. It’s a very fast and versatile method, but it comes with two major drawbacks: it can be messy, and more importantly, it’s not permanent.

While ink marking has its uses in certain industrial applications, it’s a poor choice for permanent identification. If you need a mark to last through years of use and wear, a non-permanent solution like ink is likely to fade, smudge, or be removed entirely.

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Recent Posts

The Value of Indent Marking for Permanent Identification

When you need a truly indelible mark, indent marking is a far superior option. This method physically indents the material of your product, creating a permanent mark that will remain legible and secure in almost any condition. This is especially important for compliance with government and industry standards.

For example, if you’re marking items like gun receivers, vehicle identification numbers (VINs), safety devices, or medical devices, indent marking ensures the mark adheres to legal and industry requirements.

Beyond legal compliance, indent marking is crucial for long-term part traceability. Imagine a customer trying to read a part number from a dirty, rusty car part 20 years from now. An ink stamp would likely be gone, but an indented number would still be perfectly legible.

did you know?

no-cost marking of your sample part with expert recommendations

The Benefits of Indent Marking

- Durability: Indent marking is permanent and resists fading, abrasion, and harsh environments.

- Compliance: It helps you meet strict government and industry standards for product identification.

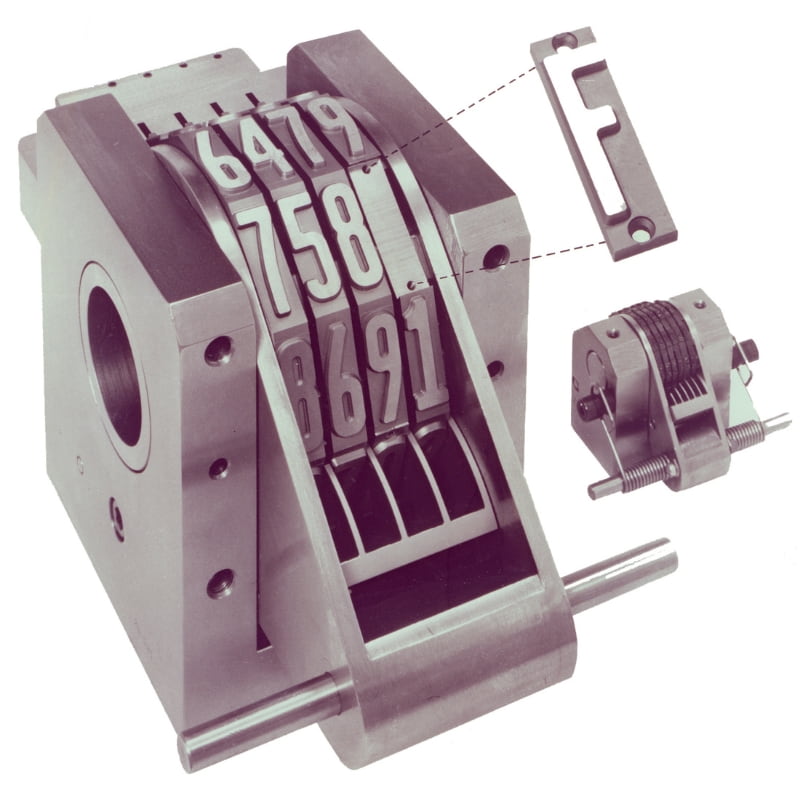

- Efficiency: On parts where the information doesn’t change, you can mark as fast as your press can run. For serialized parts, our Model 50 automatic head can operate at very high cycle rates.

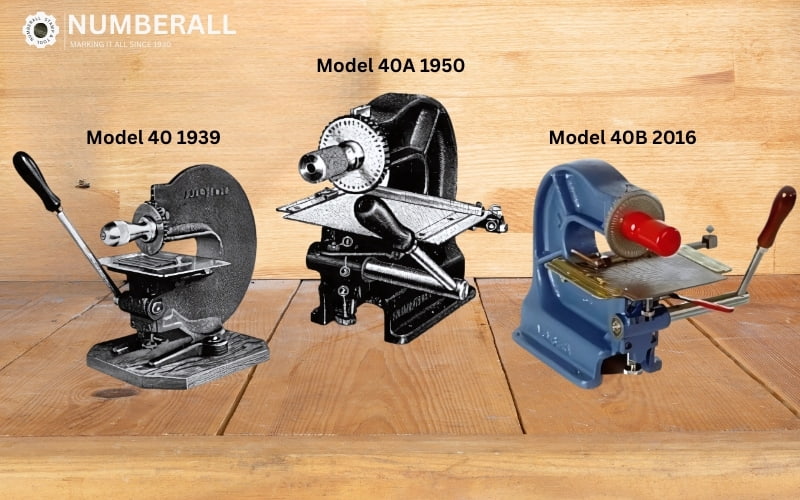

We are proud of our commitment to innovation and our role in developing the best metal marking equipment on the market. If you have more questions about how indent marking or other methods can benefit your business, please don’t hesitate to contact us!

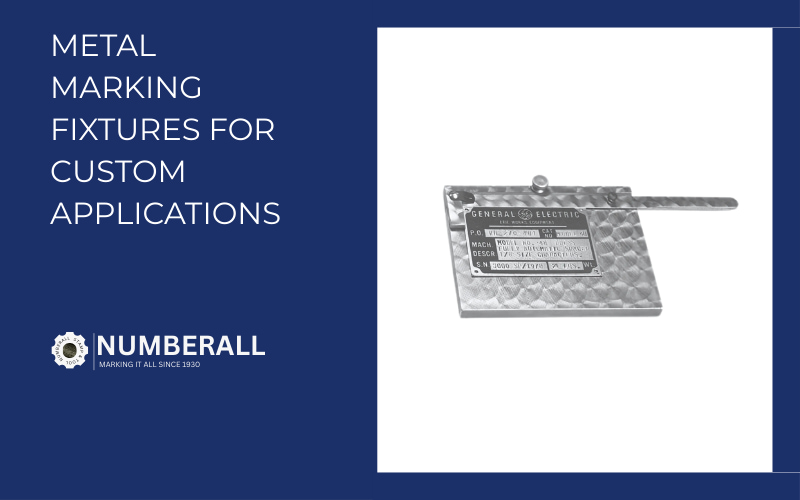

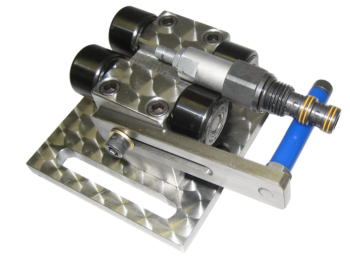

Need a custom marking solution? Have questions about character sizes or specific applications? Our team is here to help.

Looking for an economical custom solution to marking your equipment?

Discover custom metal marking solutions for your equipment. With our long history of innovation since 1930, we can meet any requirement. Making it easy to do business with us. Request a Quote today!

Recent Posts

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.