May 4, 2025Coin Marking Process, Roll Marking Presses

Marking Coin Edges with Numberall Machines

Achieve Superior Bullion Marking with Reliable, Cost-Effective Equipment

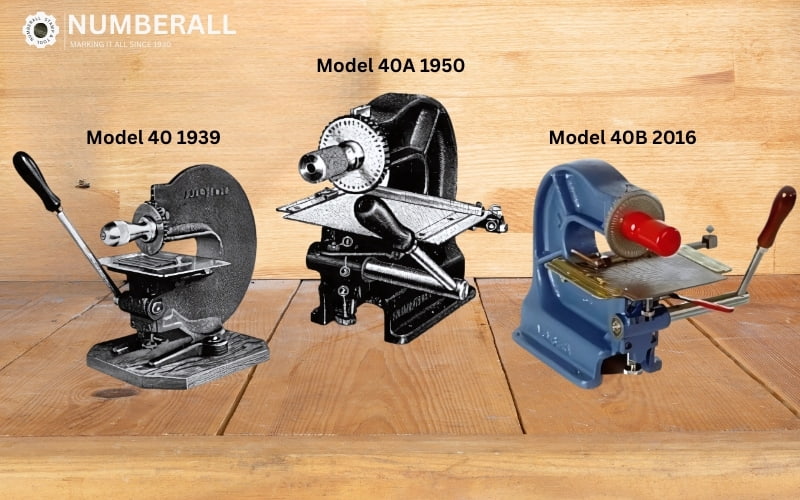

When your manufacturing operation requires precise coin edge marking for bullion, medallions, or specialty minting, quality and reliability are paramount. Numberall Stamp & Tool Co., a 4th-generation family-owned business since 1930, specializes in traditional indenting stamping equipment designed for part traceability and identification. Unlike laser, dot peen, or inkjet systems, our mechanical solutions deliver lower costs, exceptional durability, and straightforward operation—engineered for industries like manufacturing, aerospace, automotive, and medical.

Learn how Numberall’s custom fixtures and roll marking presses ensure flawless coin edge marking, empowering your production with proven, industry-trusted technology.

Why Numberall Leads in Coin Edge Marking

For over 90 years, Numberall has crafted marking machines that prioritize cost-efficiency, reliability, and precision for manufacturing applications. Our indenting equipment meets the rigorous demands of businesses needing dependable part identification without complex software. Here’s what sets us apart:

- Cost-Effective and Long-Lasting: Our machines offer lower acquisition and maintenance costs than high-tech alternatives, with lifespans exceeding 40 years.

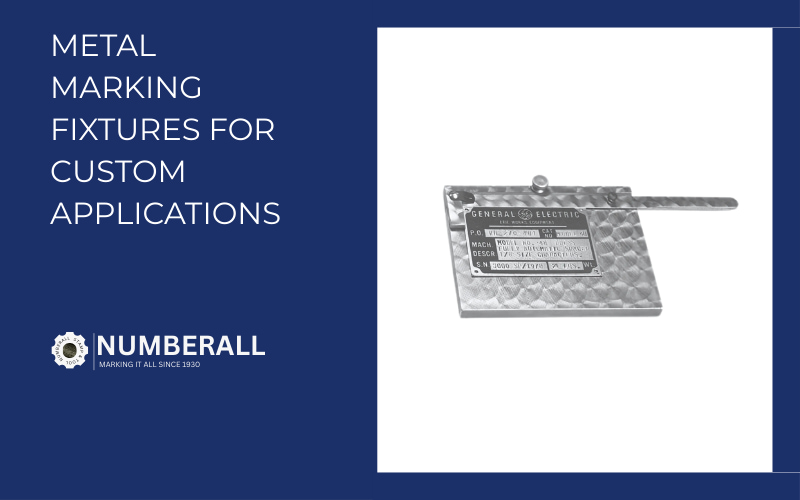

- Custom-Engineered Fixtures: We design tailored fixtures to stamp coin edges accurately, preserving surface quality across parts with varying diameters or stepped designs.

- Rapid Turnaround: Receive quotes within 24 hours and access in-stock products for swift delivery, minimizing production downtime.

- Expert Support: Our sales engineers, with decades of experience, provide lifetime support, preventative maintenance, and modifications to adapt to your facility’s evolving requirements.

- Proven Reliability: From aerospace components to submarine identification tags, our machines deliver consistent marks in demanding manufacturing environments.

Unlike competitors’ software-driven systems, Numberall’s mechanical equipment requires minimal training, eliminates software-related issues, and ensures precision with reduced downtime—ideal for manufacturers valuing efficiency and cost savings.

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Recent Posts

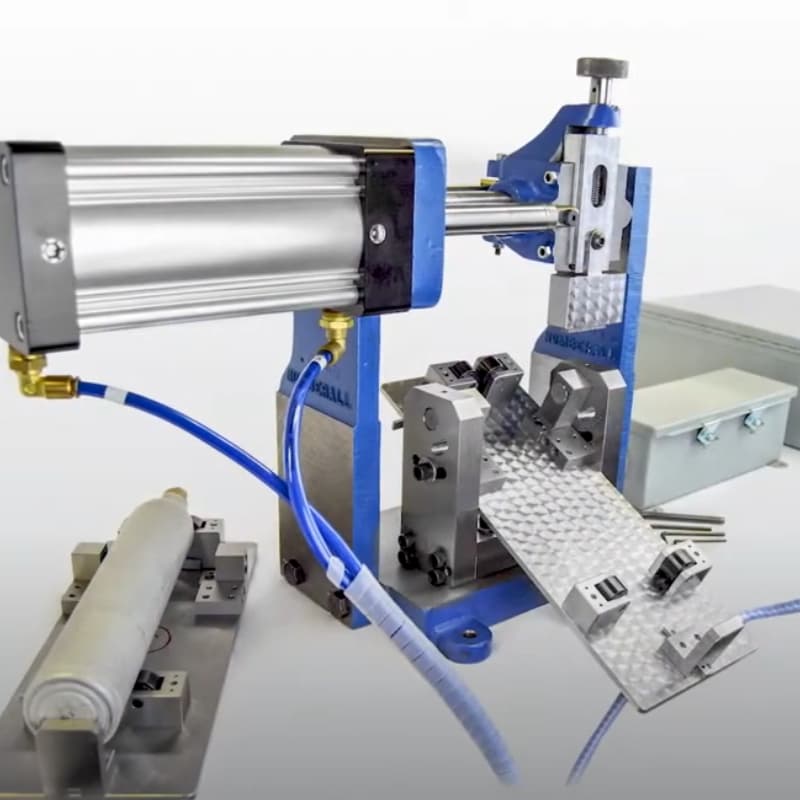

Model 301 Roll Marking Press: Engineered for Precision

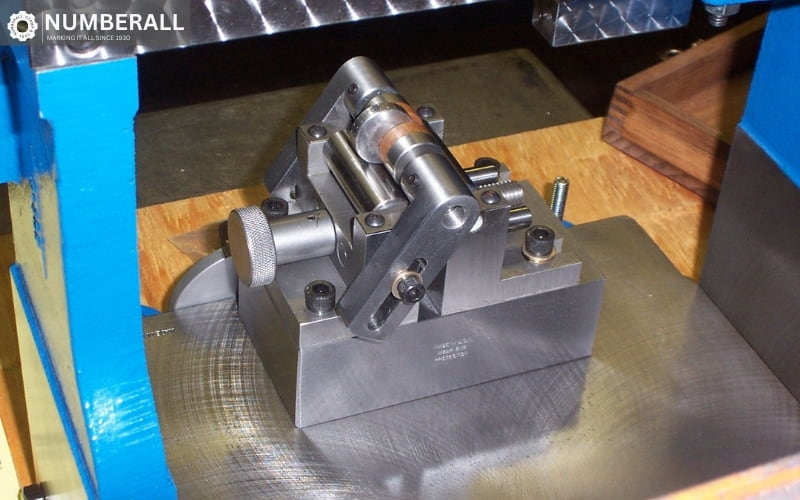

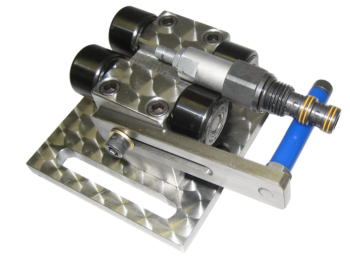

For coin edge stamping and secondary marking applications, Numberall’s Model 301 Roll Marking Press (available in hand-operated or air-powered models) is a trusted solution. Key features include:

- Versatile Capacity: Marks round parts up to 1-5/8” in diameter (larger with optional accessories), supporting character sizes up to 1/4” in aluminum or 5/32” in mild steel.

- Tailored Fixtures: Specialized fixtures secure parts, preserving the finish of coins and medallions. Interchangeable arbors support hollow parts or rings, while adjustable rollers accommodate parts with varying diameters.

- Industrial-Grade Durability: Built in the USA for rugged manufacturing use, ensuring consistent depth of impression for professional results.

did you know?

no-cost marking of your sample part with expert recommendations

Applications Across Manufacturing Sectors

Numberall’s indenting solutions support traceability across multiple manufacturing sectors:

• General Manufacturing: Durable marks for tools and components, meeting stringent traceability standards.

• Aerospace: Reliable identification for parts operating in extreme conditions.

• Automotive: Cost-effective marking for high-volume production lines.

• Medical: Precision stamping for surgical instruments and implants.

Our equipment marks components ranging from livestock identification tags to electronic parts, demonstrating its adaptability and reliability in manufacturing applications.

Why Mechanical Indenting Outperforms Modern Systems

High-tech marking systems like laser or dot peen often involve significant costs, frequent maintenance, and software complexity. Numberall’s mechanical indenting solutions provide clear advantages for manufacturers:

Feature Numberall Indenting Laser/Dot Peen

Cost Lower acquisition and maintenance costs High initial and ongoing expenses

Durability Machines last 40+ years Frequent repairs, shorter lifespan

Training Minimal, no software skills required Requires specialized training

Downtime Low, robust mechanical design Software or hardware issues cause delays

Flexibility Custom fixtures for varied applications Limited to specific configurations

For manufacturers operating in challenging environments or with budget constraints, Numberall’s solutions deliver superior value and performance.

Case Study: Custom CO2 Cylinder Marking for SodaStream

SodaStream needed a reliable solution for permanent, compliant marking on varied-size CO2 cylinders. Numberall Stamp & Tool Co., a 4th-generation family-owned business since 1930, delivered a custom Model 301 Air-Driven Roll Marking Press in just two weeks. With a custom actuation system for safe operation and a precision fixture for multiple cylinder sizes, our indenting solution ensured legible marks meeting CGA, DOT, and EN 1089-3 traceability standards, outperforming high-maintenance laser systems.

How Numberall Supports Your Decision Process

Selecting marking equipment involves thorough research, solution evaluation, and investment decisions. Numberall supports you at every stage:

- Research: Access our resources, including videos, infographics, and technical guides on marking methods.

- Evaluation: Request a sample marking to assess our quality or download our Product Matrix (link to gated content) to compare equipment options.

- Decision: Receive a custom quote within 24 hours or consult with our sales engineers to design a solution customized to your production needs.

Our family-owned legacy, partnerships with leading global manufacturers, and commitment to exceeding expectations make Numberall a trusted partner.

Why Choose Numberall?

Since 1930, Numberall has been a leader in metal marking, delivering precision indenting solutions that outperform modern alternatives. Our equipment offers durability, cost savings, and flexibility, backed by expert support and rapid response. Ready to enhance your coin edge marking or traceability processes?

- Request a Free Quote: Receive a custom quote in 24 hours.

- Schedule a Consultation: Discuss your needs with our experienced sales engineers.

- Contact Us Today: Our sales engineers are ready to help with your marking needs.

Looking for an economical custom solution to marking your equipment?

Discover custom metal marking solutions for your equipment. With our long history of innovation since 1930, we can meet any requirement. Making it easy to do business with us. Request a Quote today!

Recent Posts

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.