by Numberall | Apr 19, 2016 | Blog

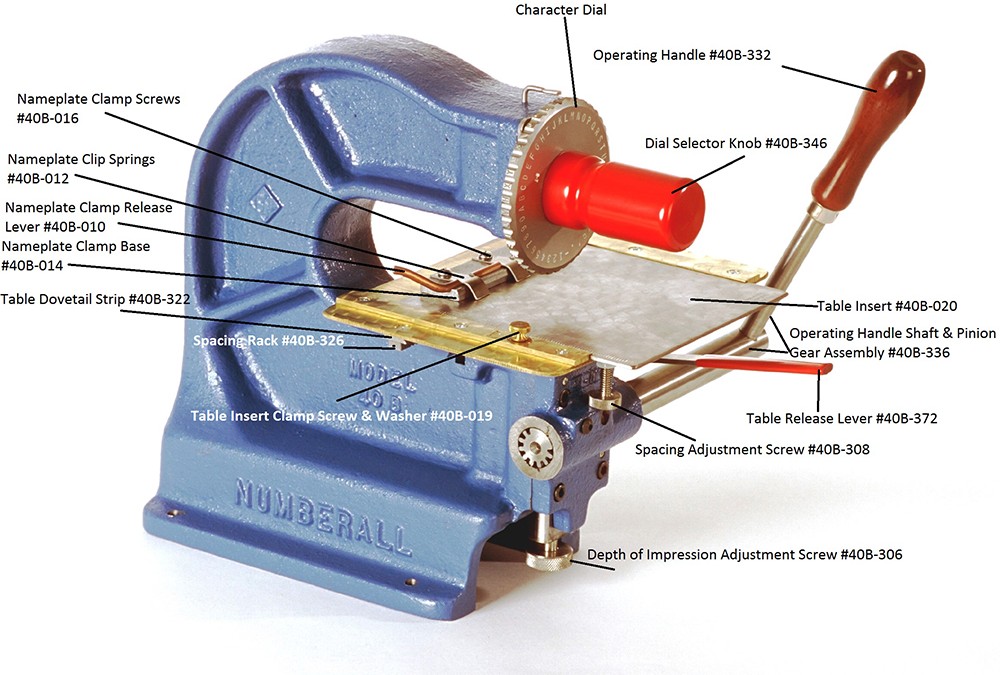

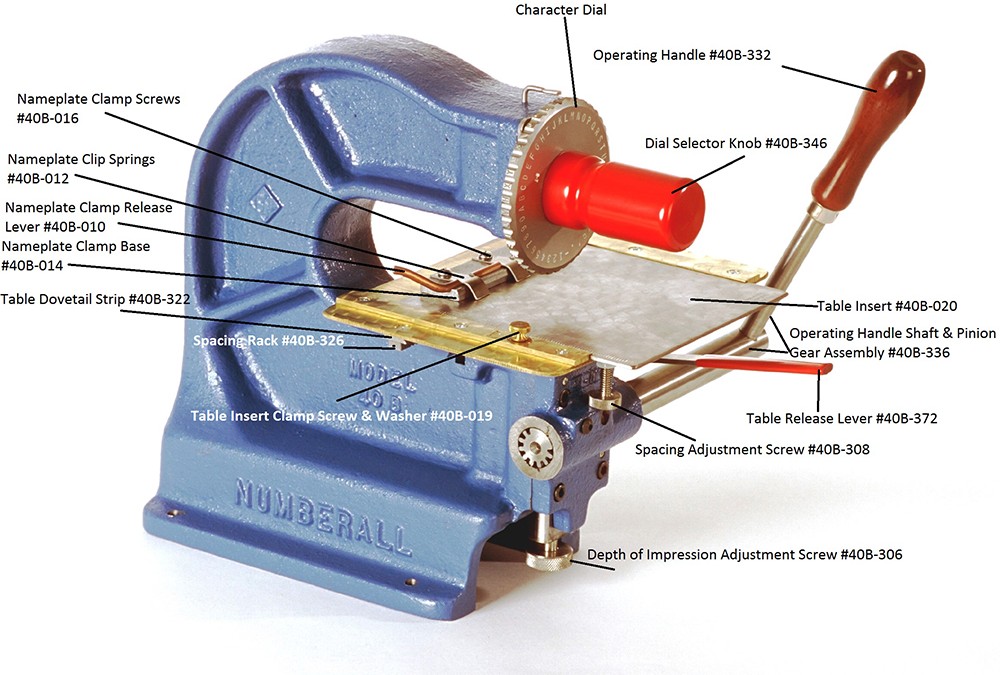

To keep your Numberall product in good working order, regular maintenance must be done. For wear items and consumables, it is almost always more cost effective to buy the parts and do the repairs. The Model 40B is an excellent, cost-effective machine to do this with as it has no plastic or electric parts that break or need to be replaced annually.

This list of recommended spare parts and maintenance, along with your owner’s manual, will help you to maintain your Model 40B for years to come:

- Table Inserts are common replacement items because they slowly warp over time from the repeated pounding. The table insert can be moved fore and aft for line spacing.

- Character Dials are meticulously engraved with 42 characters and heat-treated to last. You can choose from 1/16”, 3/32”, 1/8”, 5/32”, and 3/16” character sizes.

- Spacing Racks. Character dials are interchangeable with the addition of different spacing racks. Extra-long tables and spacing racks are available for larger parts.

- Nests and Strip Holders. We also manufacture different sized nests and strip holders to make operation even simpler. All you have to do is drop or slide the tag into the nest or strip holder and start marking.

- Light Oil. An oil hole is provided on the front of the press just below the spacing adjustment screw. A few drops of light oil should be applied here if bearing surfaces appear dry. Lubricate once a day if used continuously.

- Dry Lubricant. Use dry lubricant to grease the character dial surface that is against dial plate, the table insert guides, and the table dovetail strip. Do not use oil.

If you need help maintaining your Model 40B or would like to order parts, please contact us. We have all parts in stock for immediate delivery including parts for custom made and discontinued machines. In addition, you can request a product manual by contacting us directly.

by Numberall | Apr 5, 2016 | Blog

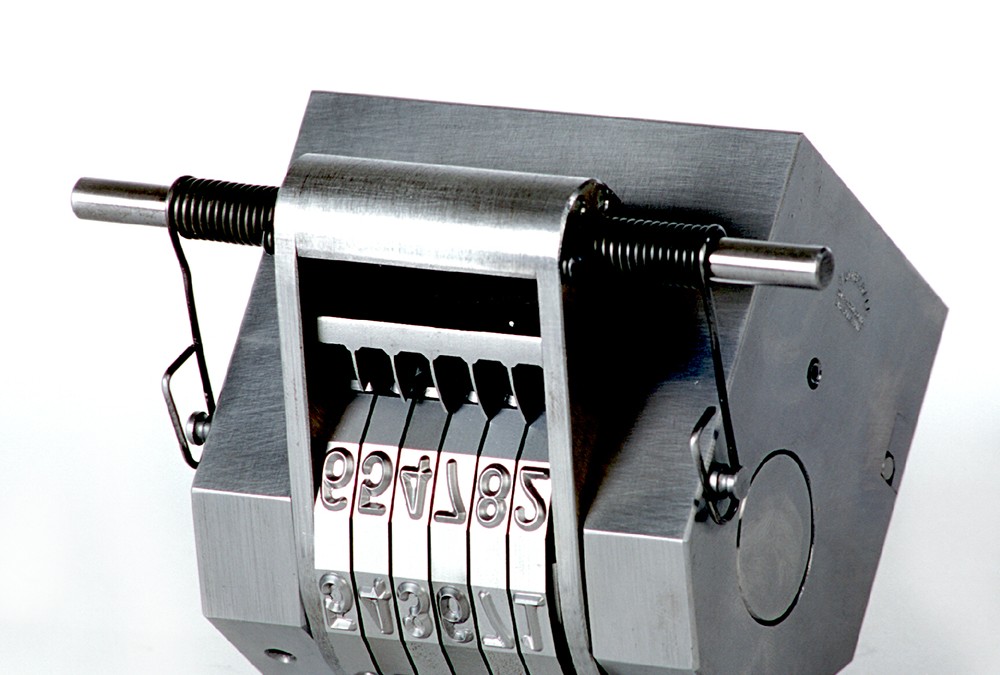

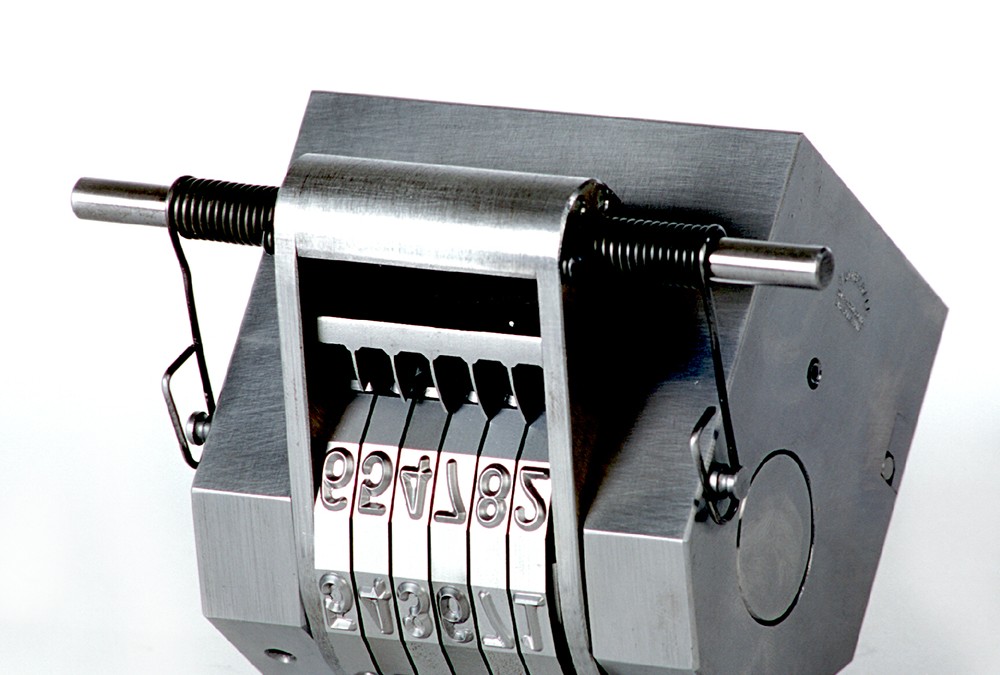

Numberall is known for products that last for decades. To make sure your machine lasts a long time, regular maintenance must be done. It is almost always more cost effective to perform regular maintenance than repair a damaged machine. The Model 50P is a machine that is a fine example of this. In fact, we are still servicing Model 50P numbering heads that are over 40 years old, a true testimonial to Numberall’s quality and design.

This list, along with your Model 50P owner’s manual, will help you to maintain your machine:

- Coil Return Springs. The coil return springs are part of the head of the Model 50P. These springs are under considerable tension and should be handled carefully. They are not required with the air trip feature, however, they will experience the most wear due to their location on the machine.

- Actuating Pawl. When removing the actuating pawl shaft, be careful not to drop the actuating pawl as it is easily broken.

- Actuating Pawl Spring. When maintaining your machine, always wear eye protection as the actuating pawl spring is under tension and could fly out. It can break prematurely due to wear, so it is recommended to keep one in stock.

- Retaining Pawls (Regular). Be careful not to bend the retaining pawls when using or maintaining your machine. If the retaining pawls are to be removed, maintain the original order for reassembly.

- Retaining Pawl (Unit). Care should be taken not to bend the retaining pawl shaft when using or maintaining your machine.

- Retaining Pawl Spring. Retaining pawl springs on numbering heads can break prematurely, so it is recommended to keep them in stock.

- Spare Wheels. Depending on use and the material being stamped, it is recommended to keep spare wheels in stock.

- Medium India Stone. If there are any burrs on the wheels or actuating arms, make sure to remove them using a medium India stone.

- Light Machine Oil. Lubricate the Model 50P. Care must be taken to ensure that dirt and grit are not in the machine before lubricating it. The tolerances are very tight, so any dirt and grit in the machine may bind or damage it. Do not lubricate a head that is to be heated as the oil will leave residue, which will bind the machine.

The location of these parts will vary on your machine based on options you’ve selected. However, the owner’s manual provides detailed images to help you identify them. If you need help maintaining your Model 50P or would like to order parts, please contact us. We have all parts in stock for immediate delivery including parts for custom made and discontinued machines. In addition, you can request a product manual by contacting us directly.