Numberall and the Future of Metal Marking

Preserving Your Production Line: Numberall's Expertise in Re-engineering Legacy Marking Equipment

In an era of rapid technological advancement, many organizations face a critical challenge: adapting modern production standards without a costly overhaul of their existing infrastructure. While newer marking methods like dot peen, laser etching, and chemical etching have their place, they often require a complete replacement of legacy tooling and fixtures.

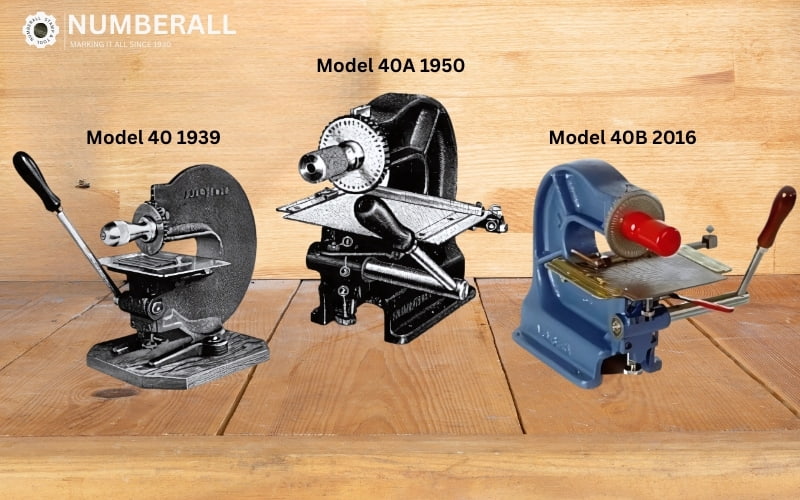

For nearly a century, Numberall Stamp & Tool Co. has specialized in industrial marking equipment that stands the test of time. Our core expertise lies not just in manufacturing durable metal stamping and serial numbering machines, but in the strategic re-engineering of our equipment to integrate seamlessly with your existing production lines. This technical proficiency allows our clients to leverage their current investments, reduce downtime, and achieve a faster return on investment (ROI). With a commitment to exceptional service, we offer quick quoting and fast lead times, ensuring your production lines remain operational and efficient.

Maintaining Production with Re-engineered Solutions

Our commitment to re-engineering is driven by a deep understanding of manufacturing processes and the need for reliable, cost-effective solutions. We work within the unique constraints of your operation to deliver custom modifications that preserve your established methods. This approach is a testament to our engineering capabilities and our dedication to solving real-world production challenges.

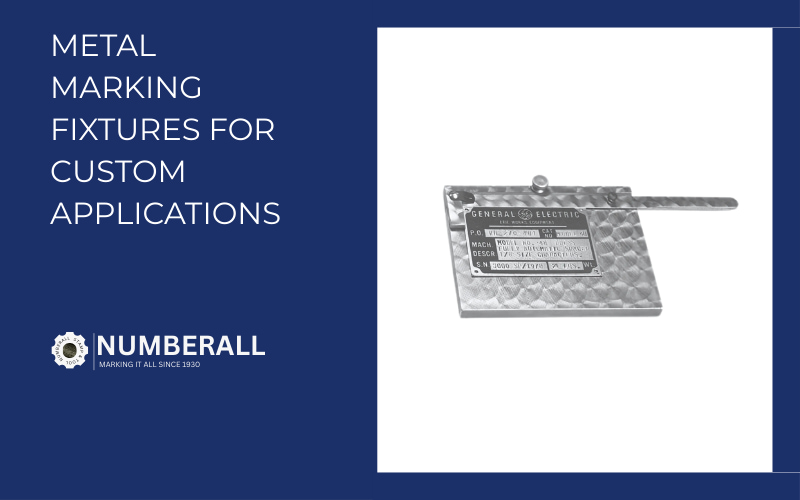

Below are several examples demonstrating how Numberall’s re-engineering expertise has provided customers with custom solutions for their specific needs.

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Recent Posts

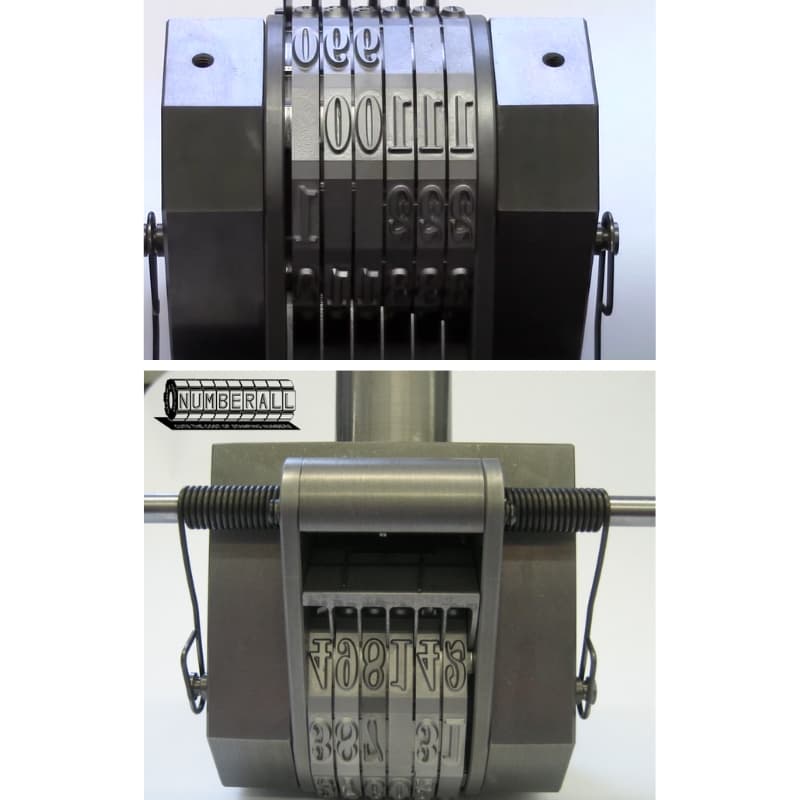

Case Study 1: Integrating New Numbering Heads with Existing Fixtures

- The Challenge: A customer required new Numberall Model 50P serial numbering heads but was constrained by their original, custom-designed marking tools and fixtures. A full replacement of their tooling would have resulted in significant expense and production downtime.

- The Numberall Solution: Our engineering team re-engineered the Model 50P numbering heads to precisely fit within the customer’s existing tooling. This required meticulous design work to ensure the heads would function flawlessly without any modification to the client’s press or fixtures. We also made the length of the impression concave to perfectly fit the specific diameter of their parts.

- The Result: The customer avoided the substantial cost and disruption of a tooling overhaul, saving both time and money. Our solution provided a modern, reliable numbering head that integrated directly into their established workflow, all with a fast turnaround.

did you know?

no-cost marking of your sample part with expert recommendations

Case Study 2: Optimized Design for Space Constraints

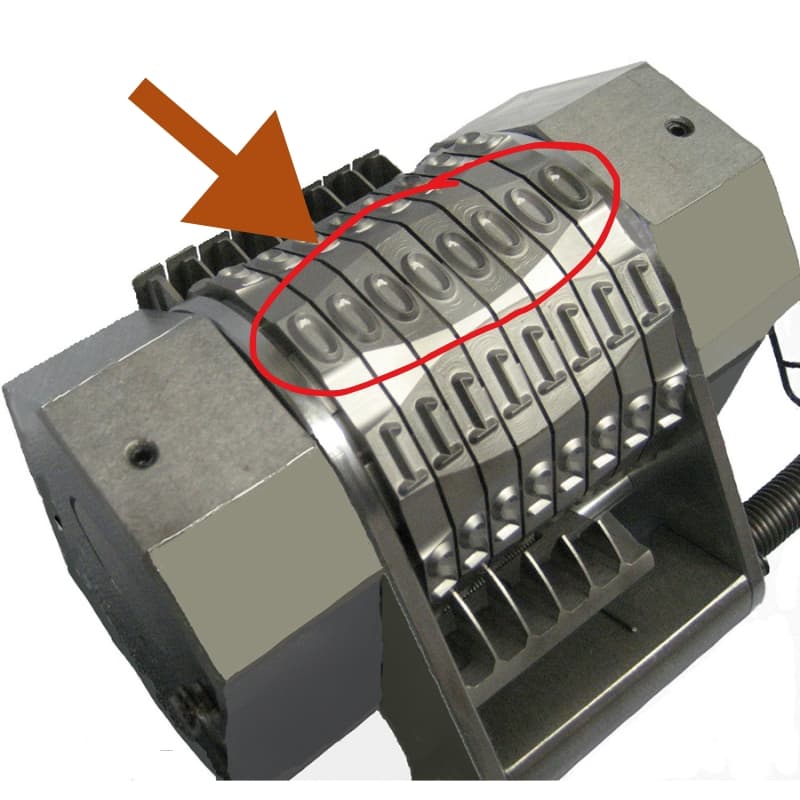

- The Challenge: A manufacturer needed a solution for a cramped production line that had no room for a standard-sized serial numbering head.

- The Numberall Solution: We resurrected an older, smaller design of the Model 50P with an 11-division wheel. This required re-engineering the legacy design to meet modern specifications while retaining its compact footprint. The smaller form factor allowed the new numbering head to be installed in the customer’s limited space without requiring any costly modifications to the surrounding press or fixtures.

- The Result: The client’s operational efficiency was improved with a custom-fit solution that eliminated the need for a costly fixture redesign and prevented a significant pause in production.

Looking for an economical custom solution to marking your equipment?

Discover custom metal marking solutions for your equipment. With our long history of innovation since 1930, we can meet any requirement. Making it easy to do business with us. Request a Quote today!

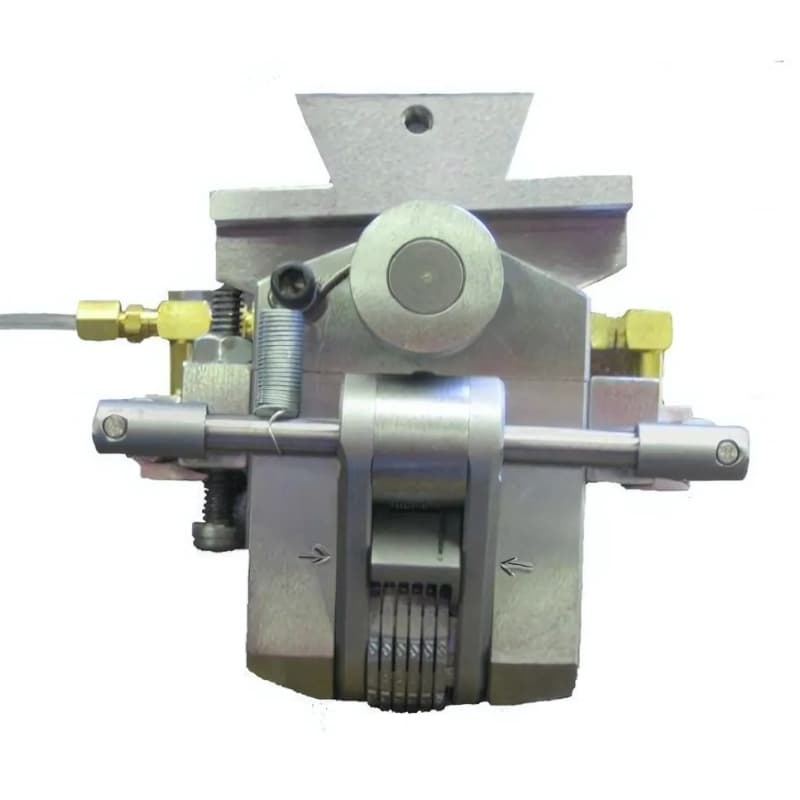

Case Study 3: Enhanced Efficiency and Maintenance

- The Challenge: A production line required a method for quickly and efficiently changing the type on a Model 50P in a space-constrained environment.

- The Numberall Solution: We modified a Model 50P to include a rotatable type retainer. This re-engineered design allows for rapid and efficient removal and replacement of type, significantly reducing the time spent on tooling changes.

- The Result: This modification led to a substantial improvement in changeover efficiency, reduced downtime, and provided a more streamlined process for the customer’s operators.

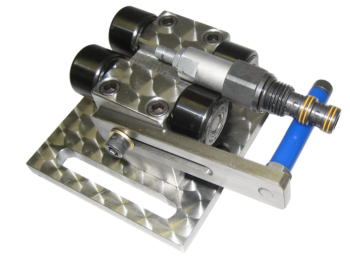

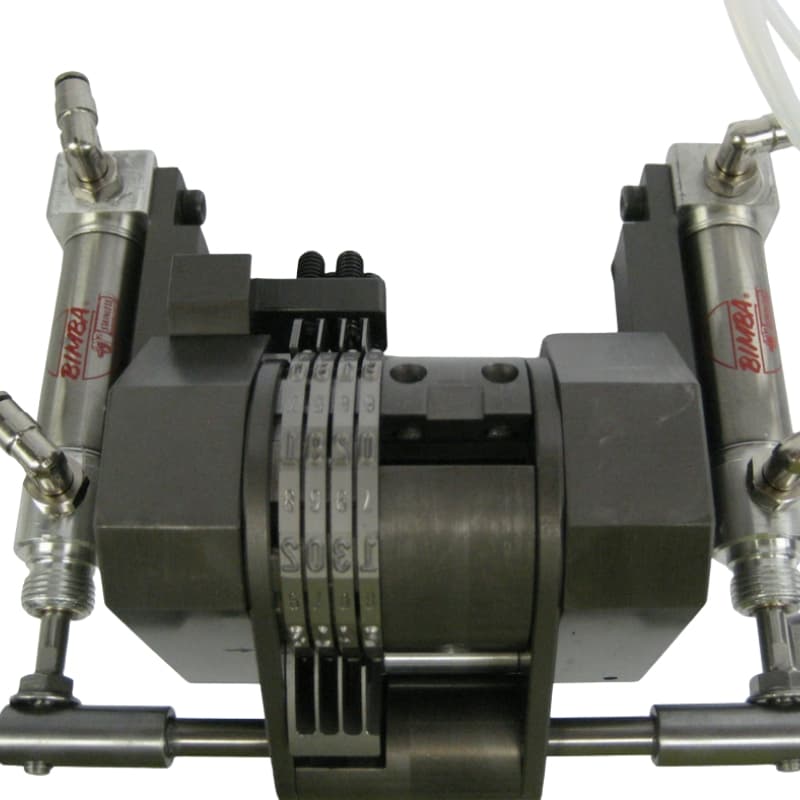

Case Study 4: Reduced Part Stress in Roll Marking

- The Challenge: A customer needed to mark a flat part on a roll marking press but was concerned that a traditional, full-force stamp would cause excessive stress or deformation to the material.

- The Numberall Solution: Our engineers modified a Model 50P by giving it a “barrel” style wheel. This specialized design allows the characters to “rock” across the part during the roll marking process, distributing the force over a smaller area. We also engineered a special adapter for the top of the Model 50P to facilitate this unique motion.

- The Result: The modified equipment achieved the required mark while significantly reducing part stress, ensuring the integrity of the finished product and improving overall part quality.

The Numberall Advantage: Decades of Experience in Metal Marking

While some marking equipment suppliers focus on newer, and often more complex, technologies, our strength lies in our deep understanding of the fundamentals of metal marking.

- Numberall’s expertise ensures that our equipment not only performs reliably but is also highly adaptable. Our re-engineering capabilities offer a powerful, cost-effective alternative to complete system overhauls, allowing you to maintain and improve your production lines with minimal disruption.

- By modifying our equipment to fit your production line—rather than forcing you to spend time and money modifying your existing fixtures—we provide superior value.

- This approach, combined with our quick quoting and fast lead times, minimizes costly production downtime and gets you back to full operation quickly.

Are you looking for a reliable, durable solution that respects your existing investment? Do you need a stamping or numbering machine re-engineered to meet the unique demands of your production line?

Contact our engineering team today to discuss how we can adapt a Numberall solution to your specific requirements.

Recent Posts

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.