by Numberall | May 22, 2025 | Hand Held Numbering Heads, Metal Marking

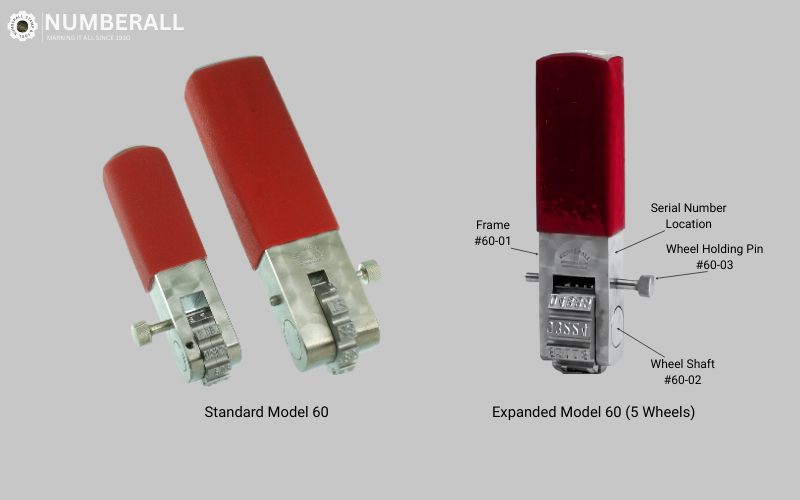

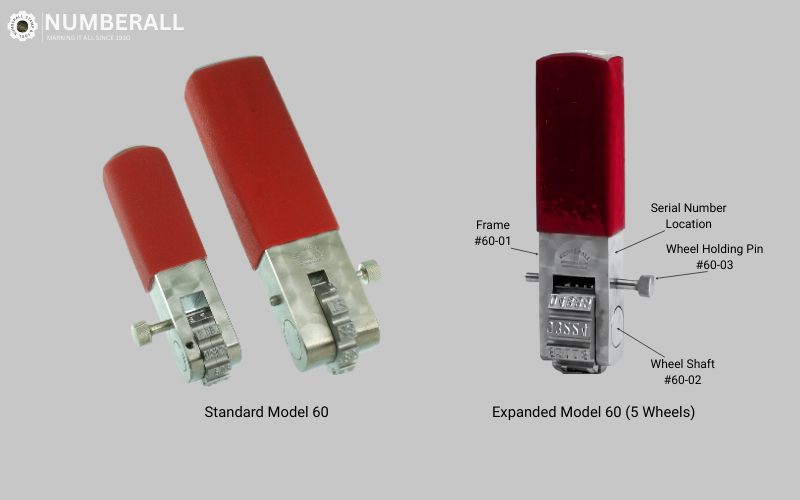

Learn about Numberall’s enhanced Model 60 Handheld Numbering Machine, now with larger 5/32” and 3/16” character sizes. Enjoy economical, durable, and versatile marking for parts, keys, tags, and more.

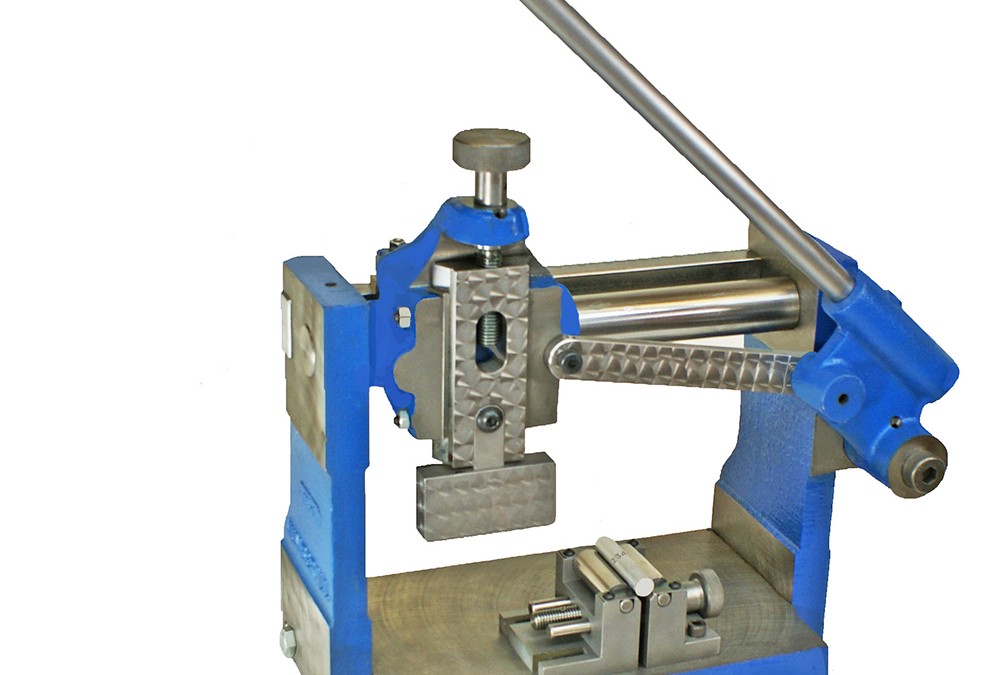

by Numberall | Mar 25, 2025 | Benefits of Indent Marking, Custom Applications, Roll Marking Presses

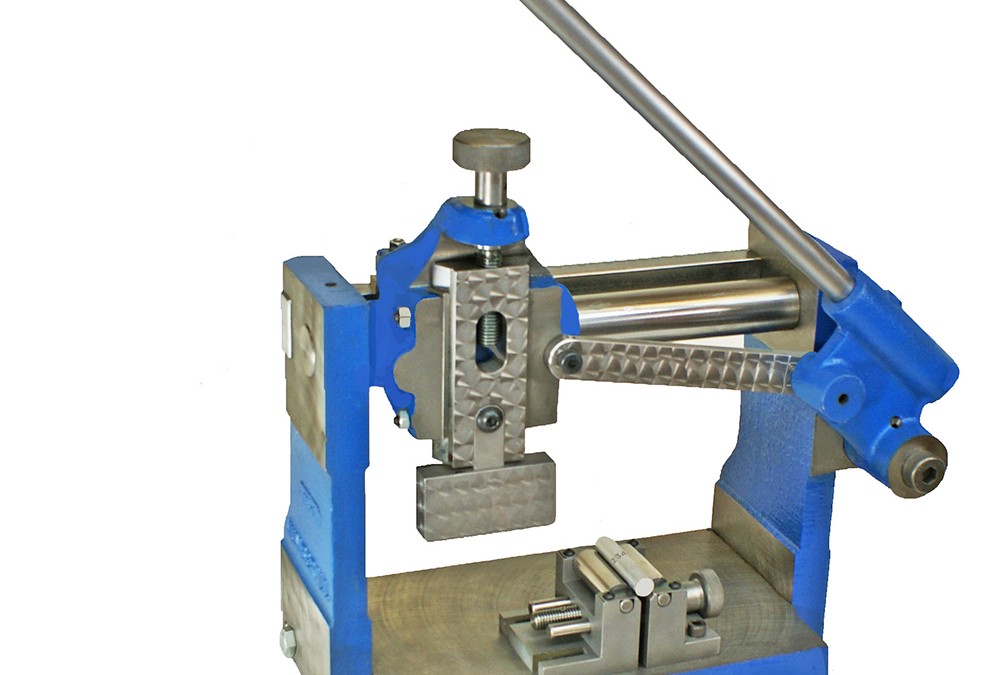

Discover Numberall’s 301A Oversize Arm Roll Marking Press for precise, durable marking of cylindrical parts. With expanded capacity and custom solutions, it’s ideal for automotive, aerospace, and more. Learn how it boosts efficiency!

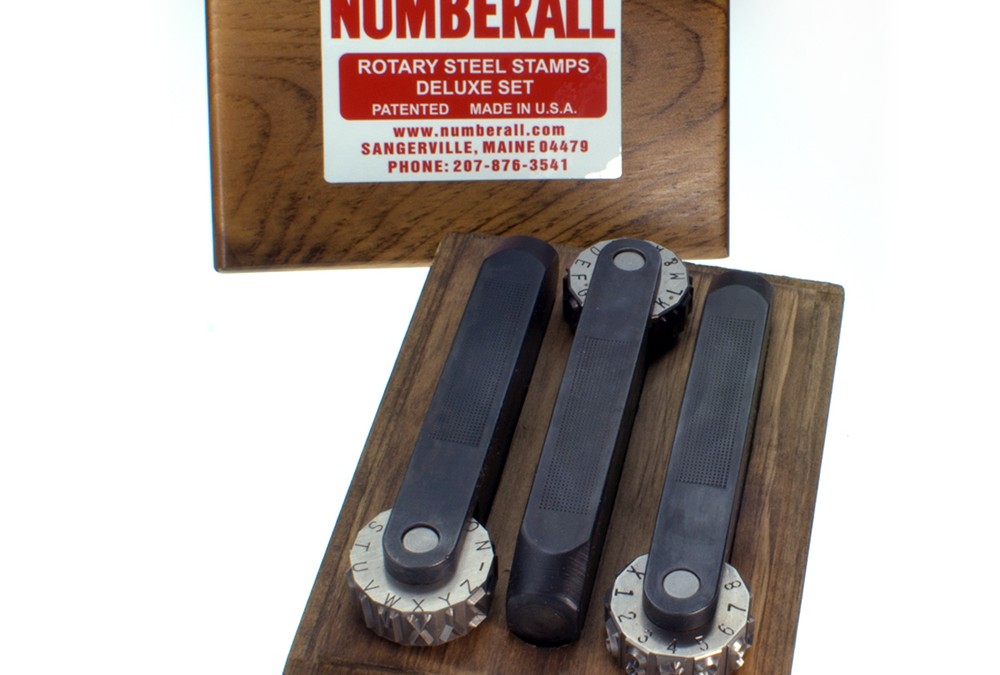

by Daniel Bayerdorffer | Jul 13, 2024 | Blog

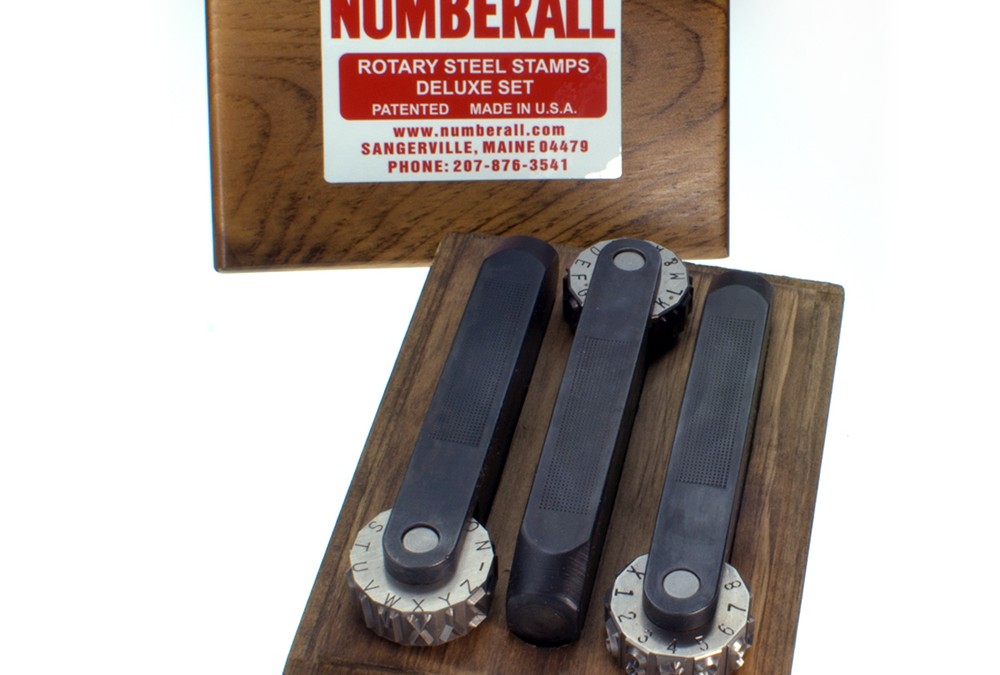

Product Spotlight: Rotary Stamps Why Numberall’s Rotary Stamps Are the Smart Choice for Durable Metal Marking Since 1930, Numberall Stamp & Tool Co., a fourth-generation family business, has led the metal indent stamping industry, offering cost-effective, reliable...

by Editor | Jun 30, 2016 | Blog

How to Space Text Using Model 40B Tutorial: How to Adjust the Model 40B’s Spacing Rack for Precision Stamping Since 1930, Numberall Stamp & Tool Co., a fourth-generation family business, has led the metal indent stamping industry, providing cost-effective,...

by Editor | Jun 15, 2016 | Blog

No matter what shape or size the item you want to mark is, Numberall Stamp and Tool Company has a machine for you. Flat pieces are the most common items that are stamped but we also have equipment to stamp round parts. Our Model 301 is the most economical solution for...