Posts: Numberall

by Numberall | Apr 19, 2016 | Blog

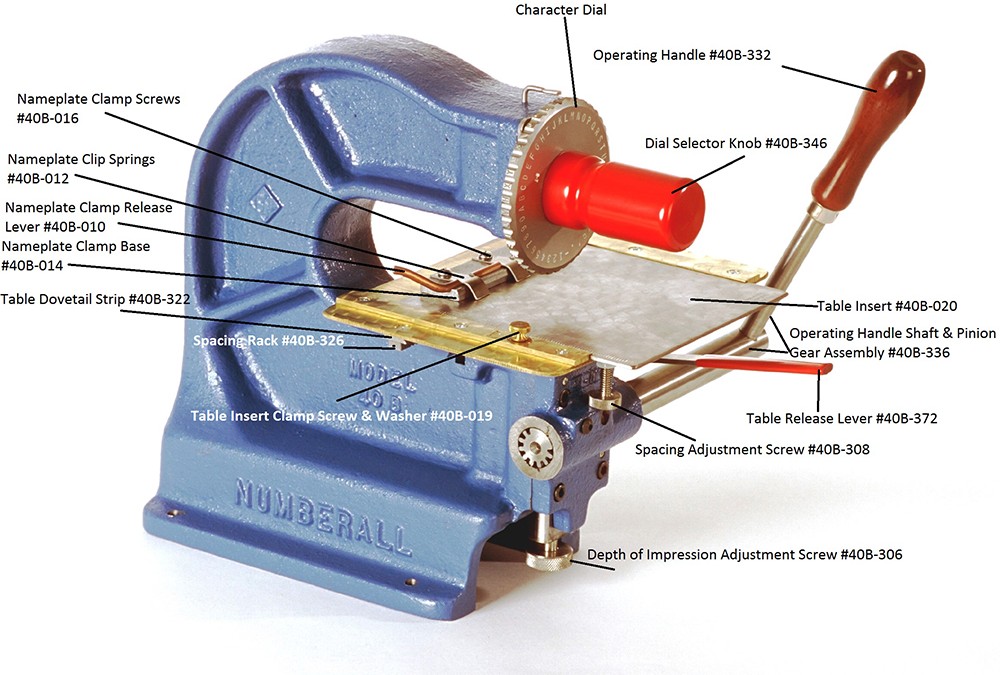

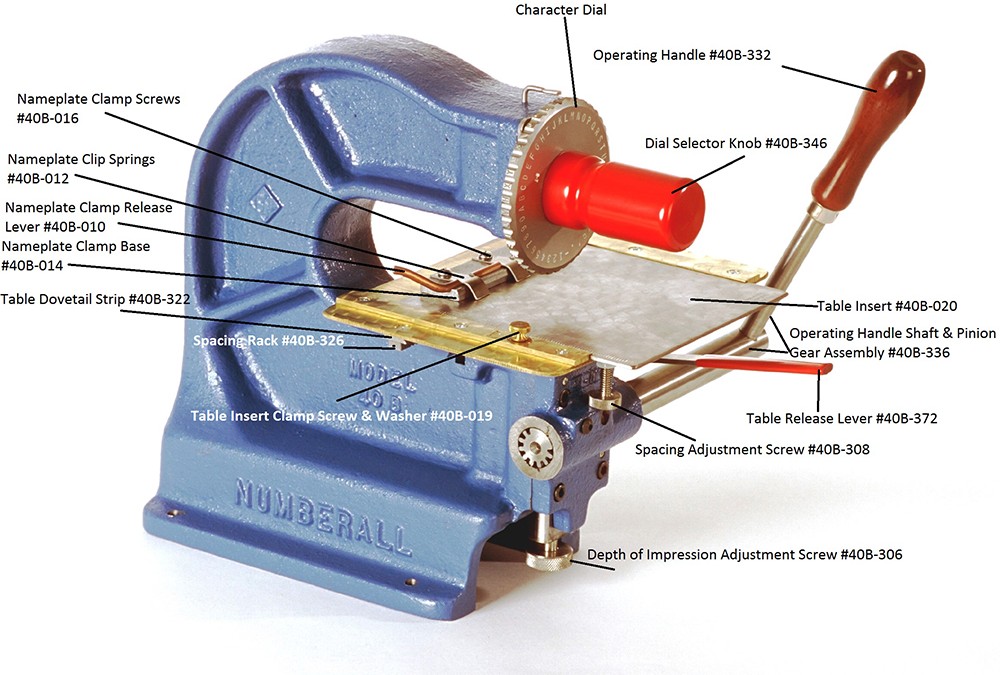

To keep your Numberall product in good working order, regular maintenance must be done. For wear items and consumables, it is almost always more cost effective to buy the parts and do the repairs. The Model 40B is an excellent, cost-effective machine to do this with as it has no plastic or electric parts that break or need to be replaced annually.

This list of recommended spare parts and maintenance, along with your owner’s manual, will help you to maintain your Model 40B for years to come:

- Table Inserts are common replacement items because they slowly warp over time from the repeated pounding. The table insert can be moved fore and aft for line spacing.

- Character Dials are meticulously engraved with 42 characters and heat-treated to last. You can choose from 1/16”, 3/32”, 1/8”, 5/32”, and 3/16” character sizes.

- Spacing Racks. Character dials are interchangeable with the addition of different spacing racks. Extra-long tables and spacing racks are available for larger parts.

- Nests and Strip Holders. We also manufacture different sized nests and strip holders to make operation even simpler. All you have to do is drop or slide the tag into the nest or strip holder and start marking.

- Light Oil. An oil hole is provided on the front of the press just below the spacing adjustment screw. A few drops of light oil should be applied here if bearing surfaces appear dry. Lubricate once a day if used continuously.

- Dry Lubricant. Use dry lubricant to grease the character dial surface that is against dial plate, the table insert guides, and the table dovetail strip. Do not use oil.

If you need help maintaining your Model 40B or would like to order parts, please contact us. We have all parts in stock for immediate delivery including parts for custom made and discontinued machines. In addition, you can request a product manual by contacting us directly.

by Numberall | Apr 5, 2016 | Blog

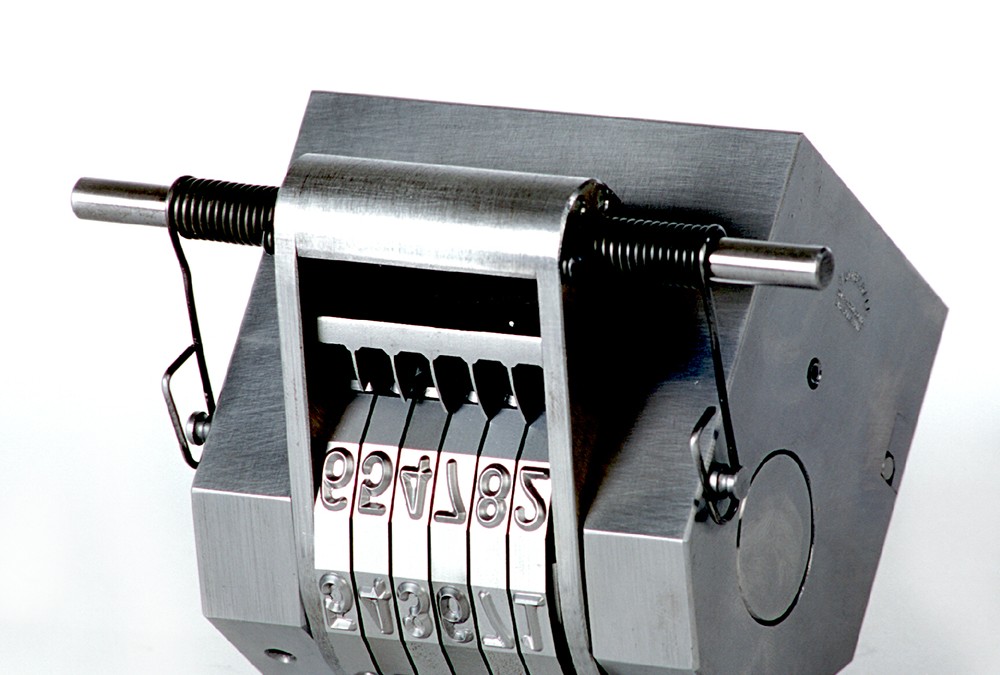

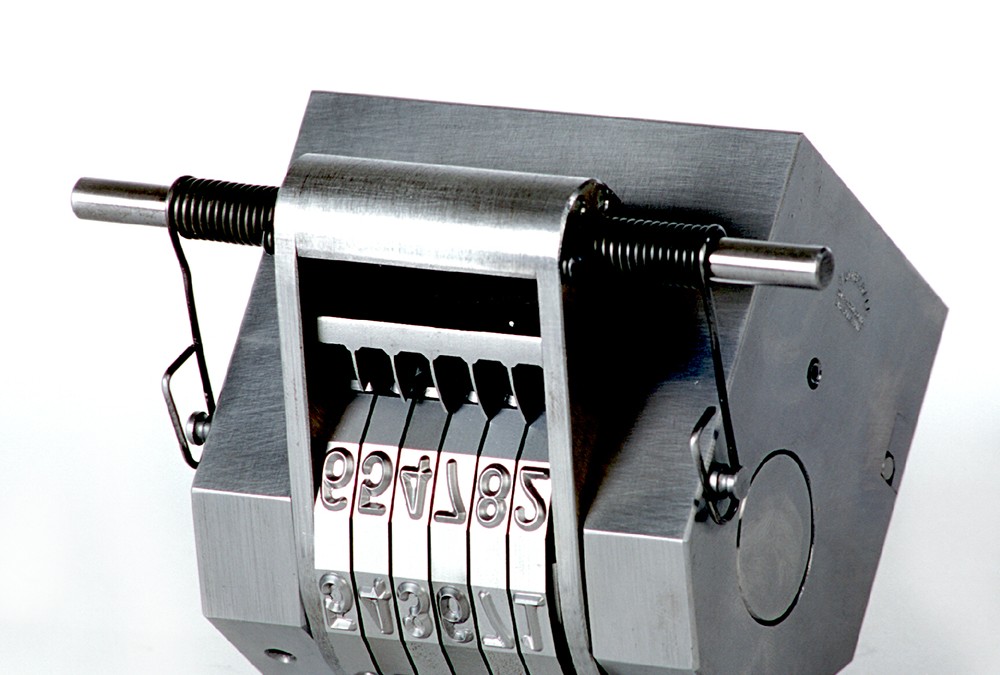

Numberall is known for products that last for decades. To make sure your machine lasts a long time, regular maintenance must be done. It is almost always more cost effective to perform regular maintenance than repair a damaged machine. The Model 50P is a machine that is a fine example of this. In fact, we are still servicing Model 50P numbering heads that are over 40 years old, a true testimonial to Numberall’s quality and design.

This list, along with your Model 50P owner’s manual, will help you to maintain your machine:

- Coil Return Springs. The coil return springs are part of the head of the Model 50P. These springs are under considerable tension and should be handled carefully. They are not required with the air trip feature, however, they will experience the most wear due to their location on the machine.

- Actuating Pawl. When removing the actuating pawl shaft, be careful not to drop the actuating pawl as it is easily broken.

- Actuating Pawl Spring. When maintaining your machine, always wear eye protection as the actuating pawl spring is under tension and could fly out. It can break prematurely due to wear, so it is recommended to keep one in stock.

- Retaining Pawls (Regular). Be careful not to bend the retaining pawls when using or maintaining your machine. If the retaining pawls are to be removed, maintain the original order for reassembly.

- Retaining Pawl (Unit). Care should be taken not to bend the retaining pawl shaft when using or maintaining your machine.

- Retaining Pawl Spring. Retaining pawl springs on numbering heads can break prematurely, so it is recommended to keep them in stock.

- Spare Wheels. Depending on use and the material being stamped, it is recommended to keep spare wheels in stock.

- Medium India Stone. If there are any burrs on the wheels or actuating arms, make sure to remove them using a medium India stone.

- Light Machine Oil. Lubricate the Model 50P. Care must be taken to ensure that dirt and grit are not in the machine before lubricating it. The tolerances are very tight, so any dirt and grit in the machine may bind or damage it. Do not lubricate a head that is to be heated as the oil will leave residue, which will bind the machine.

The location of these parts will vary on your machine based on options you’ve selected. However, the owner’s manual provides detailed images to help you identify them. If you need help maintaining your Model 50P or would like to order parts, please contact us. We have all parts in stock for immediate delivery including parts for custom made and discontinued machines. In addition, you can request a product manual by contacting us directly.

by Daniel Bayerdorffer | Mar 31, 2016 | Blog

When your products are still in use after half a century or more, you know they are of good quality. Many of Numberall’s first products ever created are still in use, which is remarkable considering we have been around since 1930. Even more remarkable is that we can still provide parts and services for all of our products.

The true test of our products’ quality is what our customers are saying about them. We have been told by many customers who have gone to competitors for lower prices that they have come back to us because our products are of better quality. If anything, our clients save money over time because our products are long lasting, even if the initial investment is larger.

All of our products are designed and manufactured in the U.S.A. This allows us to ship our products faster because they will be coming directly from our location in Sangerville, Maine. We are able to ship most products out the next day and special orders within 2 weeks of order placement.

One product that exemplifies our brand’s quality and service is the Model 50P numbering head. We can quote our standard Model 50P over the phone and ship it out in one day. For custom numbering heads, we can create a quote in 24 hours. Once quoted, we can modify the head to fit any machine, even those made by our competitors. All products are delivered about 2 weeks from when they are ordered.

If you’ve already ordered one of our Model 50P numbering heads, we can service it no matter how long you’ve had it. We are still servicing Model 50Ps that are over 40 years old. Even though we’ve made improvements to the Model 50P to keep up with industry standards, their quality remains the same. This makes a statement, not only about this model, but about Numberall’s brand as a whole. All of our products are fine examples of our quality, value, and service. For more information about the Model 50 or any of our products, please contact us.

by Numberall | Feb 3, 2016 | Blog

Whether you are a locksmith who is stamping keys or a veterinarian engraving pet tags, Numberall’s Model 40B is an ideal solution for your numbering and lettering needs. It can stamp aluminum, brass, or steel parts. Numberall’s Model 40B is the perfect machine to stamp name tags, keys, or other flat pieces. (more…)

by Numberall | Feb 3, 2016 | Blog

The history of Numberall began when Max Bayerdorffer founded the company in 1930 in Staten Island, NY. As a craftsman of bird bands, he wanted to brand his products. Along with his partner Tim Powers, Max’s creativity and craftsmanship lead to the development of the first Numberall product – a Single Wheel Rotary Stamp. As the years progressed, additional marking tools were added to the product line, including custom-built machines – some even ordered by a few of the company’s competitors.

In 1963, after the passing of his father Max, Herman Bayerdorffer took over Numberall’s leadership. In 1968, another division was opened in Sangerville, ME. In 1983, the corporate headquarters was moved from Staten Island to Sangerville, where all production takes place today. In 1996, Herman’s son, Daniel Bayerdorffer, took over the leadership at Numberall, continuing the company’s mission to create the best metal marking equipment worldwide.

Numberall’s products are used in a variety of industries on every single continent. Products that you use every day may have been stamped by Numberall equipment. You can find Numberall’s markings from the far reaches of space aboard the Apollo Lunar Lander to the depths of the oceans on board this country’s submarine fleet, and from identifying tags on cattle to sophisticated electronic components in today’s marketplace—the list of products stamped by Numberall’s machines is endless.

Numberall’s equipment can be used to mark an array of components such as nameplates, tags, keys, small parts, bushings, round shafts, and completely assembled parts. Each of these components can be marked with numbers, letters, symbols, logos, and any other identifying marks. Numberall offers the equipment to mark virtually any material from stainless steel to polyvinyl chloride.

Numberall’s wide variety of marking devices has been constantly improved and updated to reflect technological advances in the industry. The thousands of Numberall products still in service after decades of use are a testament to the quality and standards that have made the company a leader in the industry. To learn more about Numberall’s products, or to request a quote, please contact us.