Numberall’s 3 Different Metal Marking Presses and Their Capabilities

Numberall’s Comprehensive Guide to Metal Marking Presses: Capabilities & Applications

At Numberall Stamp & Tool Co., we understand that precise and durable part identification is critical across numerous industries. That’s why we offer a diverse range of high-quality metal marking presses, including roll marking presses, versatile bench-top presses, and dedicated numbering and lettering presses. Our commitment to industrial-grade construction ensures reliable performance for all your marking needs.

Many of our models are available in hand-operated, air-operated, and motorized versions, providing flexible solutions to suit various production environments and operational preferences. Let’s explore the unique capabilities and practical applications of three key types of Numberall metal marking presses.

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Recent Posts

Roll Marking Presses: Ideal for Cylindrical Part Identification

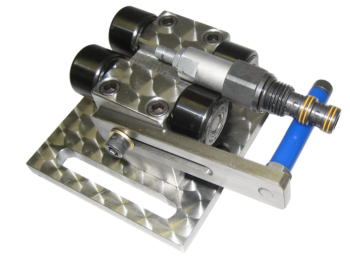

For light-duty marking of round or cylindrical parts requiring a consistent depth of impression, Numberall’s roll marking presses are the optimal choice. Our Model 301 Hand-Operated and Model 301A Air-Operated machines are engineered for efficiency and economy in industrial applications.

Key Capabilities

- Consistent Impression Depth: Designed to produce an even mark across the curved surface of a part.

- Material Versatility: Capable of stamping characters up to 1/4″ in aluminum and 5/32″ characters in mild steel.

User-Friendly Operation

- Model 301 (Hand-Operated): Simply place the round part in the adjustable holding fixture and manually pull the operating handle to engage the marking device.

- Model 301A (Air-Operated): Actuate the air valve to extend the marking device, making an even indent on the round object with minimal operator effort.

- Adaptability for Larger Parts: We offer two oversize endplates to facilitate roll marking on larger diameter components.

Typical Applications:

- Automotive Industry: Marking shafts, pistons, bearings, and small cylindrical engine components.

- Plumbing & HVAC: Identifying pipes, fittings, and valves with part numbers or manufacturer information.

- Tool Manufacturing: Engraving hand tools, drill bits, and cutting tools.

- Fastener Industry: Marking bolts, nuts, and specialized fasteners.

- Medical Devices: Marking small cylindrical instruments or components where clear identification is crucial.

did you know?

no-cost marking of your sample part with expert recommendations

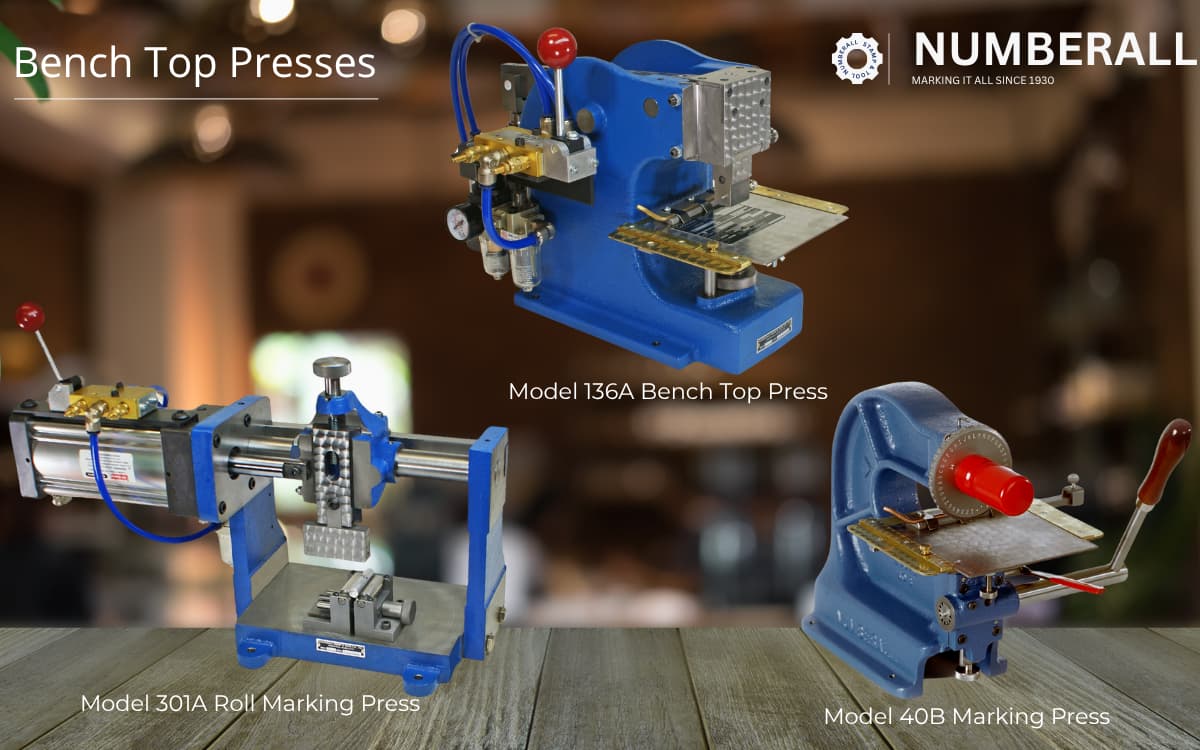

Bench Top Presses: Versatile Solutions for Flat Part Marking

Numberall’s bench top presses are engineered for precision and speed in marking nameplates, tags, and other flat objects, all without consuming valuable floor space. Constructed with robust cast iron “C” frames, these presses ensure distortion-free stamping and evenly distribute marking force across the marking device for minimal stress on the material.

Key Capabilities

- Space-Saving Design: Compact footprint ideal for workshops and production lines with limited space.

- Durable Construction: Cast iron “C” frames prevent distortion and ensure long-term reliability.

- Even Marking Force: Guarantees uniform, high-quality impressions across the entire marking area.

- Operational Flexibility: Available in:

- Hand-Operated: Model 136 & Model 131 For manual control and lower volume applications.

- Air-Operated: Model 136A and our Model 131A Offer low maintenance with very few moving parts, ideal for consistent, repetitive marking.

- Motorized: Model 137 & Model 133 Reduce operator fatigue, enhances production speed, and ensures consistent force for high-volume tasks.

Typical Applications:

- Industrial Nameplates: Marking machinery, equipment, and asset tags with serial numbers, model numbers, and safety information.

- Electrical Components: Identifying circuit boards, control panels, and electrical enclosures.

- Aerospace & Defense: Marking component tags for traceability and compliance.

- Tool & Die Shops: Marking dies, jigs, and fixtures.

- Personalized Products: Creating custom dog tags, jewelry, and commemorative plaques.

- Small Batch Production: Ideal for short runs where a dedicated, high-speed machine might be overkill.

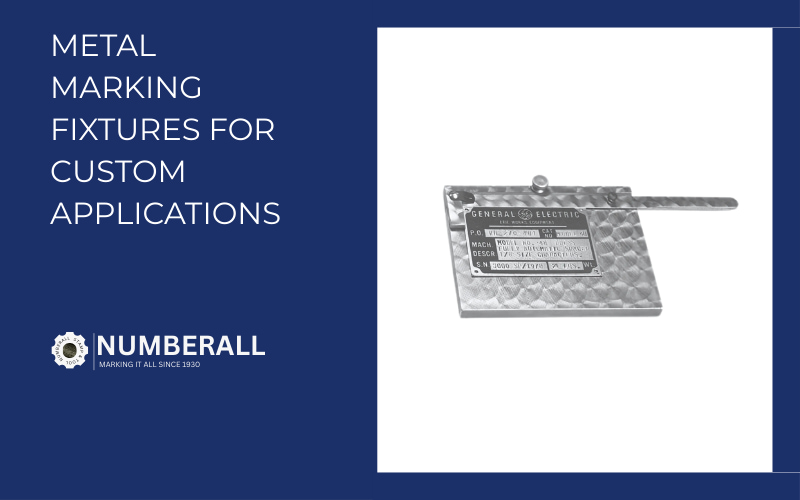

Looking for an economical custom solution to marking your equipment?

Discover custom metal marking solutions for your equipment. With our long history of innovation since 1930, we can meet any requirement. Making it easy to do business with us. Request a Quote today!

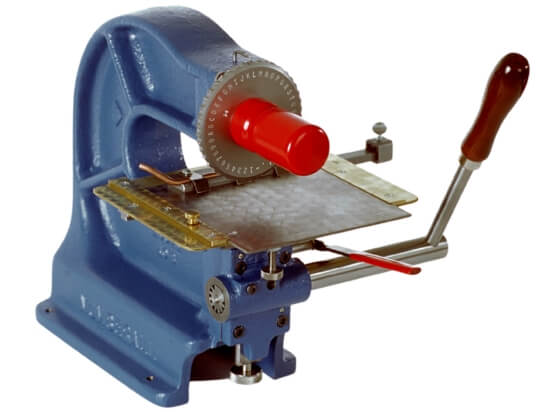

Numbering & Lettering Presses: Precision for Sequential and Alphanumeric Marking

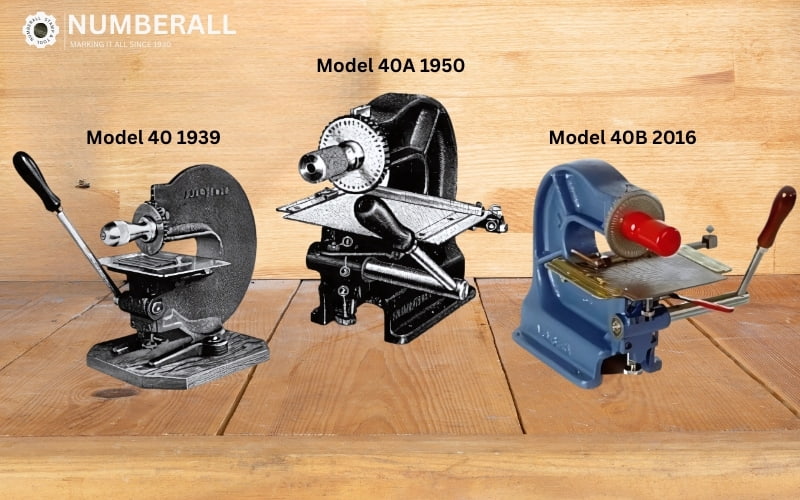

When it comes to efficiently numbering and lettering flat metal parts, Numberall’s Model 40B and Model 94 presses stand out for their high-quality construction and minimal operator effort. These presses are specifically designed for applications requiring sequential numbering, batch coding, and detailed alphanumeric identification.

Key Capabilities

- Sequential Numbering: Easily advance numbers for unique part identification.

- Alphanumeric Marking: Capable of marking both numbers and letters for comprehensive coding.

- Character Size Versatility:

- Model 40B: Stamps character sizes from 1/16” to 3/16”, depending on the material and application.

- Model 94: Better suited for thicker parts and larger characters, ranging from 1/8” to 3/8”.

- Custom Tooling: We custom manufacture nests, strip holders, and slides to precisely meet your unique marking needs, ensuring accurate placement and efficient operation.

Typical Applications:

- Asset Management: Marking inventory tags, equipment, and property with unique identification numbers.

- Automotive Parts: Stamping VIN plates, engine blocks, and component serial numbers.

- Security & Traceability: Creating social security plates, keys, and security tags with sequential numbers or codes.

- Pet Tags & Identification: Producing durable and legible pet tags with owner information.

- Tool Identification: Marking tools for inventory control and loss prevention.

- Military & Government: Stamping identification plates and components for regulatory compliance.

Choose Numberall for Your Industrial Marking Needs

While our presses are designed for remarkable versatility, you can also be confident that they are built with exceptional durability and longevity in mind. Numberall Stamp & Tool Co. has a long-standing reputation for providing robust and reliable industrial marking solutions.

Whether you require a dedicated press for cylindrical parts, a versatile bench-top solution for flat components, or a specialized machine for sequential numbering, Numberall has the expertise and equipment to meet your demands. Our team is ready to help you find the perfect metal marking press to enhance your production efficiency and ensure clear, lasting identification.

For more information on our diverse range of metal marking presses, or to request a personalized quote for a custom marking solution, please don’t hesitate to contact us today.

Recent Posts

Sign Up For Numberall News

Receive important product & pricing updates and metal marking tips.

Can round steel gun barrels be stamped with this machine?

Hi John,

The Model 301/301A will mark around the diameter. Typically barrels are marked length wise with the axis.

These machines are not set up to mark length wise.