Modified Model 50P

Numberall can modify any of our marking tools. In this application our customer asked us to produce our Model 50P to fit a specific area. (more…)

Numberall can modify any of our marking tools. In this application our customer asked us to produce our Model 50P to fit a specific area. (more…)

Numberall repairs and rebuilds their products. A few weeks ago, we received a Model 50P for repair. It just needed a couple parts, cleaning & oiling. In continuous use since 1947. How many manufacturers can supply parts and repair 73 year old tools? We shipped it, the day after the customer approved the quote. A testimony to Numberall’s quality and support. As always Made in USA!

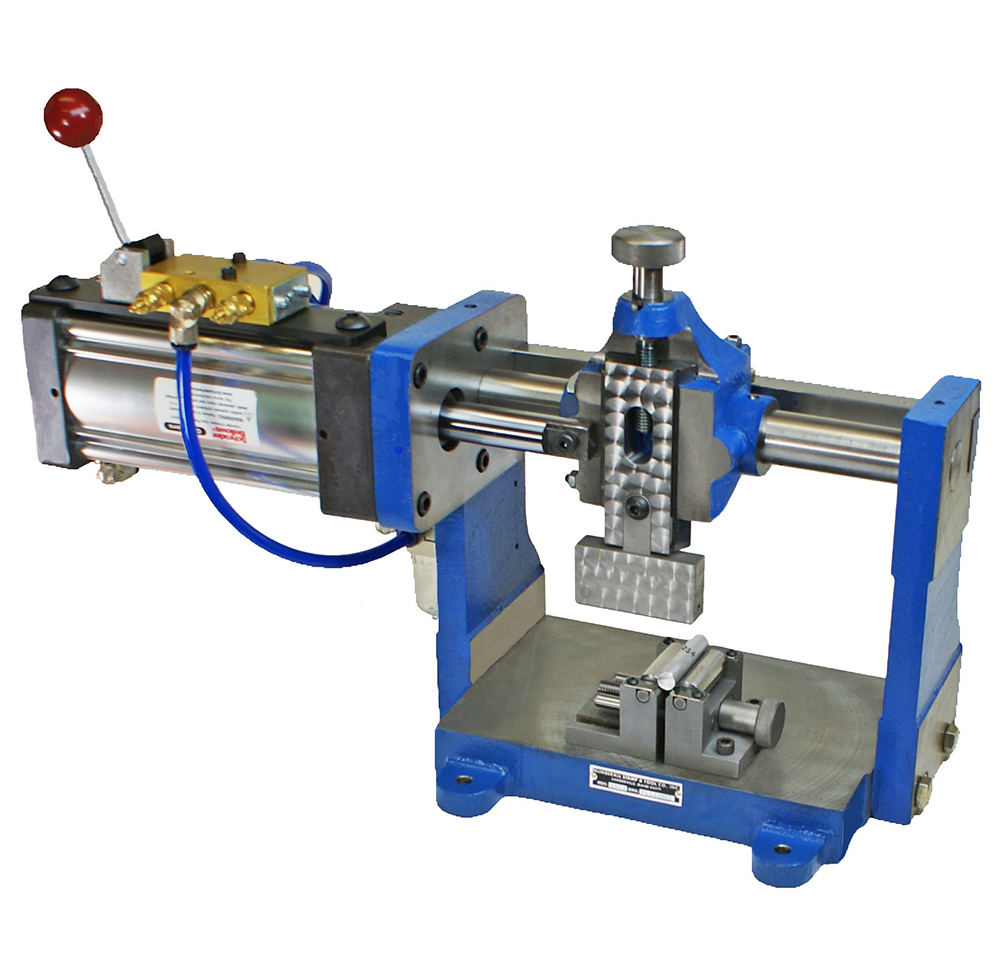

Numberall manufacturers identification equipment for all industries. Here’s a custom setup for marking coins. Using the Model 301 hand operated cylindrical marking press to mark around the edge of the coin. We used our standard adjustable holding fixture and added adjustable stops and non-marring clamp faces. Designed for a range of coins from 3/4″ to 2-1/4″ diameter, with a thickness of 3/32″ to 1/4″.

This customer uses our Model 23P Type Holder and standard steel type to put a special message around the coin.

This setup has oversize endplates for additional clearance. We also, made a series of riser blocks, to fit under the fixture to raise the coins within the adjustment of the sliding head. This is needed when going from small diameters to large diameters. Our Model 301-A can be used for this application.

If a serial number is needed, we recommend our Model 50P. An option would be to extend a frame leg and make a slot to hold type or a special logo. Various other styles of marking devices are available and can be customized to suit the application.

We can also supply other fixtures for products that require information to be stamped around the part. Made in the USA!

Numberall has just shipped a custom Model 50P for stamping serial numbers. We had to make additional angled clearance cuts, change the return springs from a coil to an extension style, put a large character on a smaller wheel design. Our customer had clearance issues that was solved with some creative engineering. As always, Made in USA!!

What’s cooler than a picture of the world’s oldest known Ferrari?

ANSWER: The same Ferrari with a Numberall press in the foreground!!

Numberall has customers from every industry you can imagine. It’s always neat to see our products being used in something special. Our products aren’t used in the Ferrari, but they are being used in SCG custom built cars.

Here is a link to a story on Scuderia Cameron Glickenhaus,

https://www.autoweek.com/…/the-last-real-privateer-james-g…/

Very nice article with more photos of Numberall products with exotic cars.

Numberall can also help with other marking requirement. We provide marking tools for producing serial numbers, part numbers, dates code and other product identification. We have marking tools that can be used with hot stamping presses as well as cold stamping applications. We can provide tools that are hand held or press mounted. We offer small bench presses that can be used rather than tie up a production press on the shop floor. We can customize our marking tools. We also build special tooling and fixtures for those difficult to mark parts.

As always, Numberall products are Made in the USA!

To request more information about our marking tools, please feel free to contact us using the form below.

Numberall has a complete line of standard type available from stock. We also make custom

type to fit virtually and application. We specialize in making steel type for all

packaging machinery and other machine designs. For those applications that require brass type, we

can supply that as well.

There are many styles that can be manufactured. Plain body, offset, tapered, special notches,

double notches, rectangular, square, round etc. Please refer to the print for common styles.

If your style is not listed, we can still make it!

A detailed print or a sample character is required for quoting. Depending on material, delivery

can be 1 to 3 weeks. As always, Made in USA!

As we continue to understand the impact of the COVID-19 virus, Numberall remains committed to the well-being of our employees and customers. We are doing our best to follow the recommendations from the CDC.

The products we manufacture supply the world with materials that are essential to all types of industry. Some of our customers have emailed that our products are essential to their organization.

Therefore, we will remain open and continue to operate. We are maintaining our parts inventory, as well as being able to provide new marking tools. However, you may experience minor delays in fulfilling orders, due to reasons beyond our control. We will advise at the time of ordering.

We are all in this together. We hope everyone stays safe and healthy.

At Numberall, we offer a diverse line of quality numbering heads with specific capabilities for serializing or simply marking a product or date code on a variety of materials. However, when determining which product will best suit our customer’s needs, we often find that it isn’t obviously clear when a serializing head is needed, versus our other consecutive marking products. (more…)

This month marked the 15,000th sale of the Model 40B, our longest-running and most popular metal stamping tool. Designed to make a consistent, long-lasting mark on nearly any flat metal surface, the 40B has been at the heart of Numberall’s business for over 80 years. The 15,000th sale was made to the maintenance department of an Alaskan hospital, where the machine will be used for key stamping. (more…)

At Numberall, we pride ourselves in offering a diverse line of high-quality marking machines, each with their own specific use. When it comes to marking small round parts, we’ve designed specialized presses that can get the job done more efficiently and effectively, with the same accuracy and quality that our equipment has become known for throughout the 90 years we’ve been in business.

Roll marking, or cylindrical marking, is a method of marking solid or hollow round parts, such as pipes and gears. At Numberall, we design our roll marking machines specifically for light duty marking of round parts with an even depth of impression. With typical flat metal marking equipment, it can be difficult if not impossible to get an even mark across a round part. Will roll marking, the part rotates, or rolls, with the indenting device to ensure each character is distributed evenly and with the same depth of impression. Our versatile roll marking equipment can be used on a wide range of materials across many different manufacturing industries, including firearms, automotive parts, pipe fittings, and more.

At Numberall, we offer two options for roll marking equipment — the Model 301 Hand-Operated and Model 301A Air-Operated presses. Although similar, these models offer unique capabilities that make them suitable based on the volume of our customer’s marking needs.

The Model 301 is a hand operated machine which is capable of mark round parts with characters up to 1/4” in aluminum, or 5/32” characters in mild steel. Despite its compact bench-top size, this press is able to incorporate oversized endplates for more clearance. To begin stamping, you will need a marking device. Many of our numbering heads can be used with the Model 301, including Model 23 Type Holder, Model 70P Non-Automatic Numbering Head, and Model 50P Automatic Numbering Head. Each unique numbering head offers customization when paired with the 301 roll marking press.

The Model 301A is ideal for high production application. This model uses an air cylinder for power and includes a control valve. The Model 301A can stamp characters of the same size, in the same material as the Model 301. The Model 301A can also incorporate oversized endplates for larger diameter parts — just like the Model 301. Similar to the Model 301, numbering heads, type holders, or marking dies are used in conjunction with the Model 301A. The key differentiator is that the Model 301 is air-operated rather than by hand, which allows for large scale production marking needs.

No matter the shape or size of the item you want to mark, it’s likely that we can customize one of our roll marking machines to meet your needs. In addition to the oversized endplate options, Numberall has designed custom fixtures to stamp the edges of coins and medallions without marring the surfaces. We also have fixtures with interchangeable arbors for stamping hollow parts or rings. For parts with varying part diameters or stepped parts, we can modify our standard adjustable holding fixture rollers to hold the part securely when marking.

One example of our custom roll marking capabilities is an application we created to mark CO2 bottles. In this design, we created special holding fixtures to mark the neck of the bottle at an angle. To see this application in action, view our recent blog post: Numberall’s Custom Application to Mark CO2 Bottles. Our roll marking machines offer both precision and flexibility for our customers looking to indent round parts. If you would like to learn more about our roll marking machines or have questions about a custom application, contact Numberall Stamp and Tool Company today!

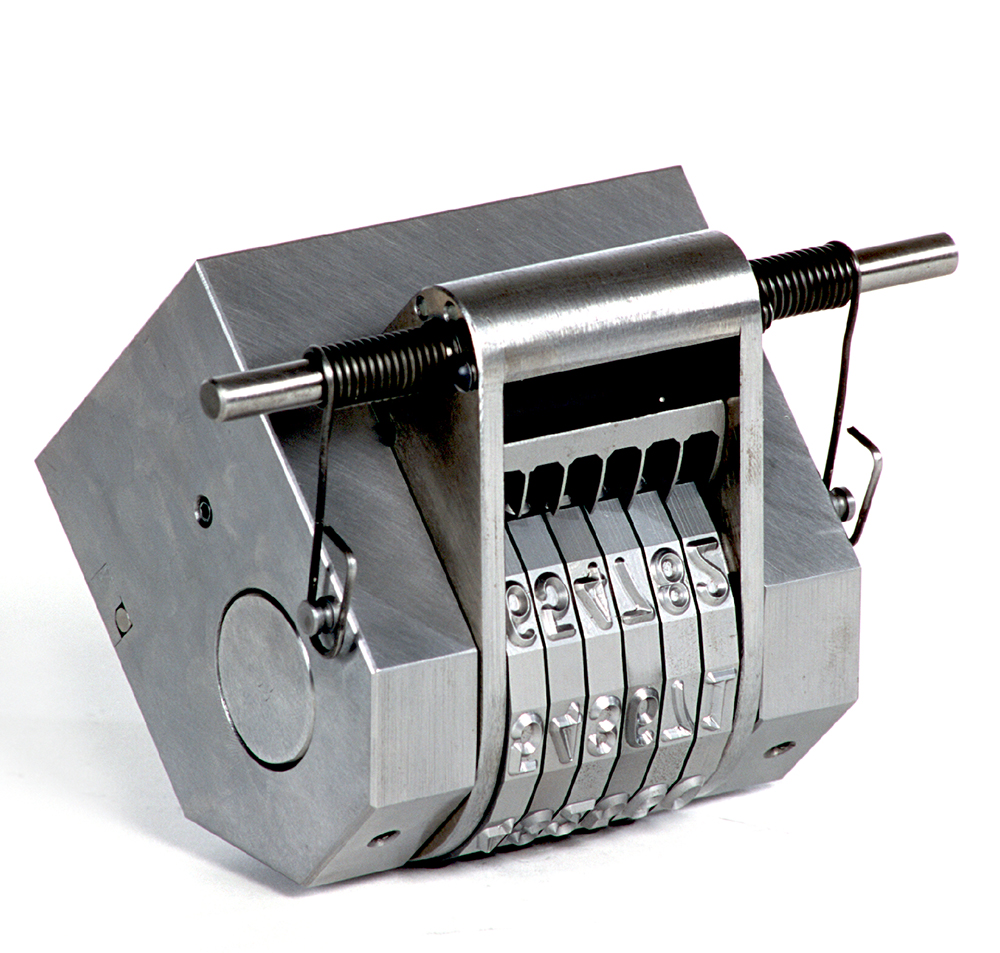

Numberall’s Model 50P automatic numbering head represents the finest marking device in the industry for rapid and accurate consecutive numbering. Like many of our other marking devices, this model’s road to becoming a well-known device in the metal marking industry is unique. Numberall produced the first Model 50P in the fall of 1935, after many months of planning and engineering. The goal was to provide customers with a machine that could precisely and efficiently mark a number of materials consecutively with minimal effort from the operator.

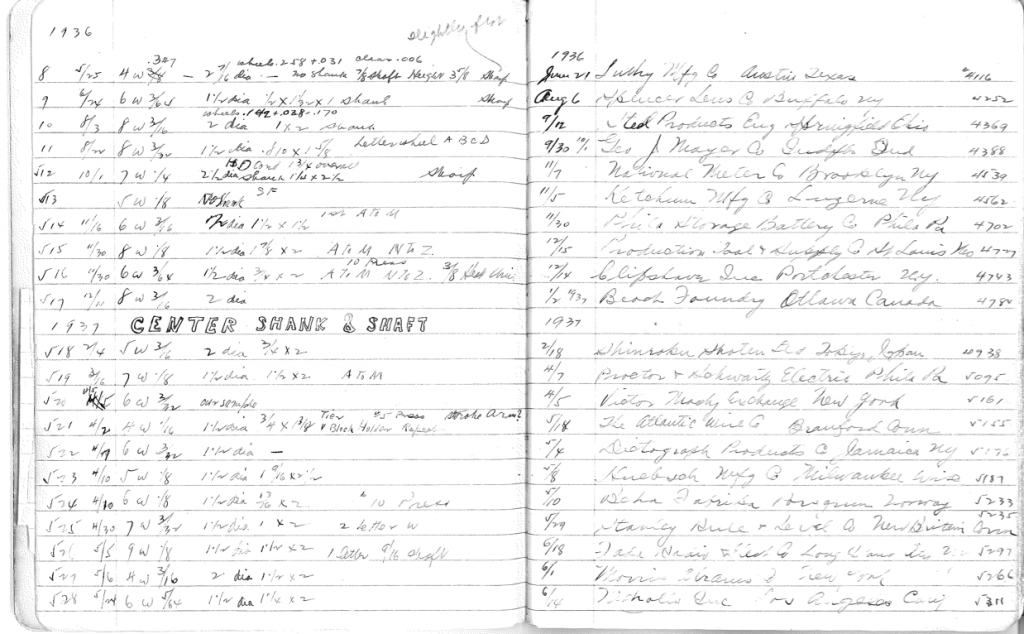

One of the first Model 50Ps that came out of production was purchased by a company we still do business with today. In 1936 Ketchum Mfg., an identification tag manufacturer in Lake Luzerne, NY, bought the 13th Model 50P that was produced. Like Numberall, Ketchum is a multigenerational family-owned company. Mr. Hopping, one of Numberall’s employees who was in charge of producing the Model 50P at the time, made note of the sale to Ketchum Mfg. in the serial number pages seen below.

Many years later we were able to obtain Ketchum Mfg.’s Model 50P, which they had modified over the years, to display in our archives.

Numberall has manufactured thousands of Model 50Ps since the first production over 8 decades ago. Through the years, the 50P has been steadily improved to increase its effectiveness and usability for clients with various uses. For example, we added a pawl block to improve wheel alignment and operation. Each wheel is now one CNC-machined component, and the actuating pawl is CNC wire EDM machined. We’ve updated the machining methods of other Model 50P parts for smoother operation and less hand fitting. It is because of this commitment to quality and durability that we are still servicing numbering head units that are over 40 years old.

Like all our machines, this model is built with heavy duty tool steel and is precision heat-treated for extensive usage over a long product life. Today’s Model 50P offers:

In addition, the Model 50P is compatible with a variety of optional equipment to increase its versatility, including hot stamping equipment for marking plastics. Numberall also offers custom applications for the Model 50P, such as an extended frame leg for a removable logo die, allowing for custom serialization.

After decades of producing and perfecting this model, you can be sure that the Model 50P is equipped for high quality marking for many years to come. If you’d like to learn more about the Model 50P, or request a quote for a custom application, please contact Numberall Stamp and Tool today.

At Numberall Stamp and Tool, we take pride in our ability to offer high-quality stamping equipment. These stamping tools can be used to mark a variety of materials across several different industries. While we have a wide range of products that we offer, we also can create high-quality custom marking tools at our customer’s request.

We recently received a request by a customer looking to create a concrete stamp that could be used to imprint their logo into wet concrete. They needed something that was durable, easy to handle, and could accurately imprint concrete for a lasting mark. Our solution was a custom concrete stamp: we created a resin image of their logo in-house and attached it to a ¼” aluminum plate. The plate’s grooved round handle was designed to help the customer utilize this lightweight stamp with ease. To apply the stamp, all the customer has to do is simply push the stamp into the wet concrete to imprint their design.

Our custom concrete stamp directly met the customer’s needs — offering them a portable product that leaves a lasting impression and at a very short turnaround time. We were able to deliver the customer their product in only two weeks’ time. This custom product was created by our team of skilled craftsmen by utilizing durable lightweight materials. We chose aluminum to create this stamp because of its light weight and resistance to corrosion to help improve the product’s life span. We are proud to produce tools of the highest quality standards and manufactured right here in the United States — many of our customers are still using our products 30 years after purchase.

Our custom concrete stamps are just one way that we can customize and create products to meet your needs in a timely manner. Whether your company is looking for a metal stamping product or you are in need of a custom design for a unique application, we’d be happy to help. Contact Numberall Stamp and Tool Company today!

Numberall has been a recurring attendee of EASTEC, the leading Northeast manufacturing trade show, since 1998. This past May, we were eager to attend the three-day event in West Springfield, Massachusetts. We find that EASTEC always proves to be educational and inspirational, as we often return encouraged by the presentations and experiences of customers, fellow vendors, and speakers alike. It turns out the 2019 conference wasn’t any different.

This year, EASTEC featured over 700 exhibitors with technical presentations, workshops, and keynote speakers. Stepping back into our booth in the exhibit hall, we had the pleasure of meeting many new faces and demonstrating some of our popular equipment, including the Model 40B, the Model 301A with Model 50P stamping round parts, and the Model 136A stamping screwdriver handles. A trend we noticed in meeting with new companies is the need for steel stamps and marking tools—products Numberall has been manufacturing since inception in 1930. Why use steel stamps instead of a machine? One reason is they are economical—not only are they affordable, but they are also made to last. Another reason is the steel stamp’s precise marking. Since the operator controls the force of the hammer, you can ensure that a clear mark is created every time. With these qualities along with their durability, we found that Numberall’s steel stamps were the right fit for a lot of companies’ metal marking needs.

Though we were pleased to meet many new people at the conference, one of our favorite things about EASTEC was being able to meet past and current customers who we may have only spoken to over the phone or through email. One customer who stopped by our booth this year had used Numberall products for over 80 years! In 1936 Ketchum Mfg. in Lake Luzerne, New York, purchased the 13th Model 50P that came out of production, a model that we only began manufacturing a year prior.

If you missed this year’s EASTEC conference, you’ll have to wait until 2021 to attend this biennial event. However, if you have an immediate marking need, please don’t hesitate to reach out to us today! Whether it’s a steel stamp set or a numbering machine, we have several options to help you mark metal more efficiently. Of course, we take custom orders too! Contact us online today for more information, or give us a call at 800-685-3072.