by Numberall | Mar 26, 2019 | Blog, News and Press Releases

From the very beginning, Numberall has been a family-owned and operated business. In 1930 Max Bayerdorffer founded Numberall, and over the next 89 years the Bayerdorffer family has been at the heart of the business, passing the torch from one generation to the next. The latest is Alexander, Max’s great grandson, who started working at Numberall full-time just two years ago– but his history with the company goes back much further than that.

by Numberall | Dec 22, 2018 | Blog

Numberall Celebrates 50th Year Operating in Maine A Golden Half-Century in Maine: Numberall's Enduring Legacy of American Manufacturing For over 50 years, Numberall Stamp & Tool Company has proudly called Maine home, solidifying its commitment to American...

by Numberall | Oct 8, 2018 | Blog, Type & Type Holders

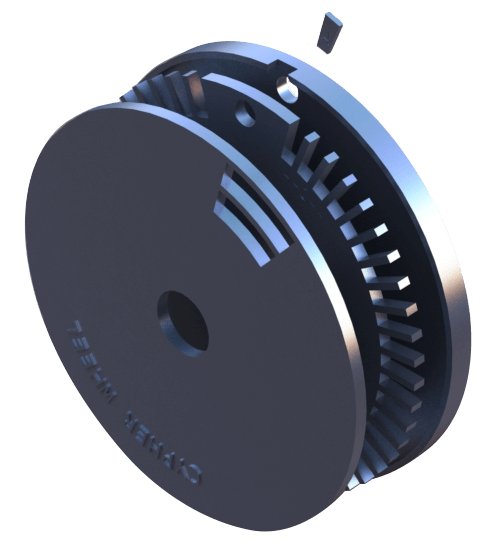

Order the 2019 Date Code Die Request More Information With fall colors painting a beautiful scene for us here in Maine, we are reminded that we too soon the holiday season will be upon us and not long after that we will celebrate a new year. If you have a Numberall...

by Numberall | Feb 27, 2018 | Blog

How to Secure a Bitcoin Wallet For over 90 years, Numberall Stamp and Tool Company has been synonymous with precision and reliability in the metal marking industry. We’ve built our legacy on crafting durable, high-quality equipment right here in the USA,...

by Numberall | Nov 27, 2017 | Blog

Order Your 2018 Date Code from Numberall As the weather gets colder here in Maine and the month of November marches on, we’re reminded of the fact that 2017 is ending and we’ll soon welcome a new year. If you have a Numberall machine and regularly use your date code...

by Numberall | Apr 24, 2017 | Blog

Numberall at EASTEC 2017 A Guide to Finding the Right Metal Marking Equipment at Manufacturing Trade Shows For manufacturers, attending a trade show is more than just a networking opportunity—it’s a chance to solve real-world production problems. When you’re looking...

by Editor | Jun 30, 2016 | Blog

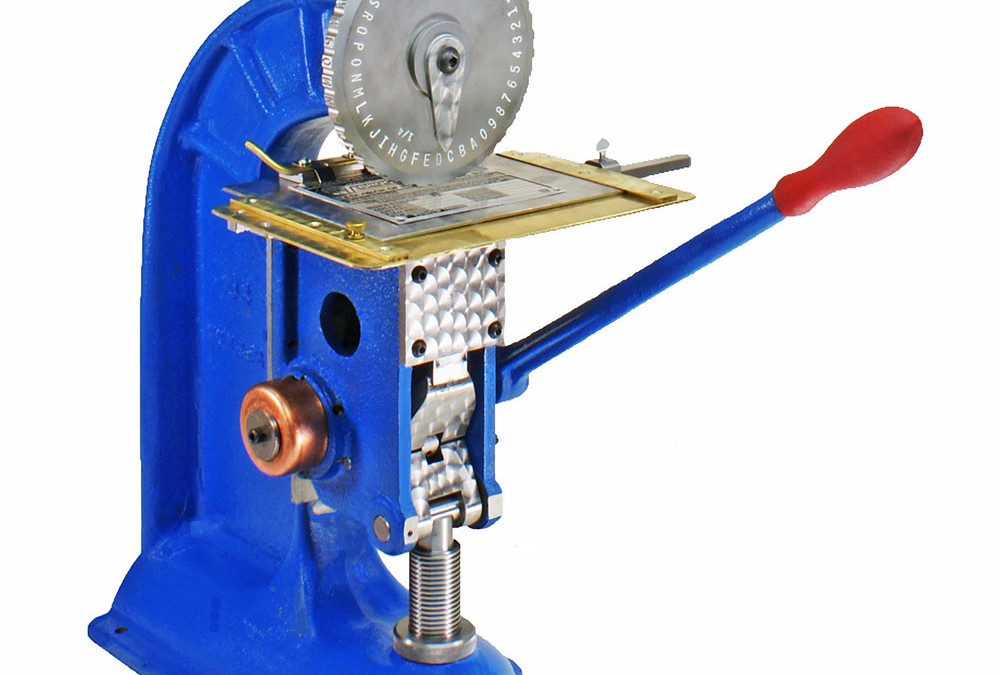

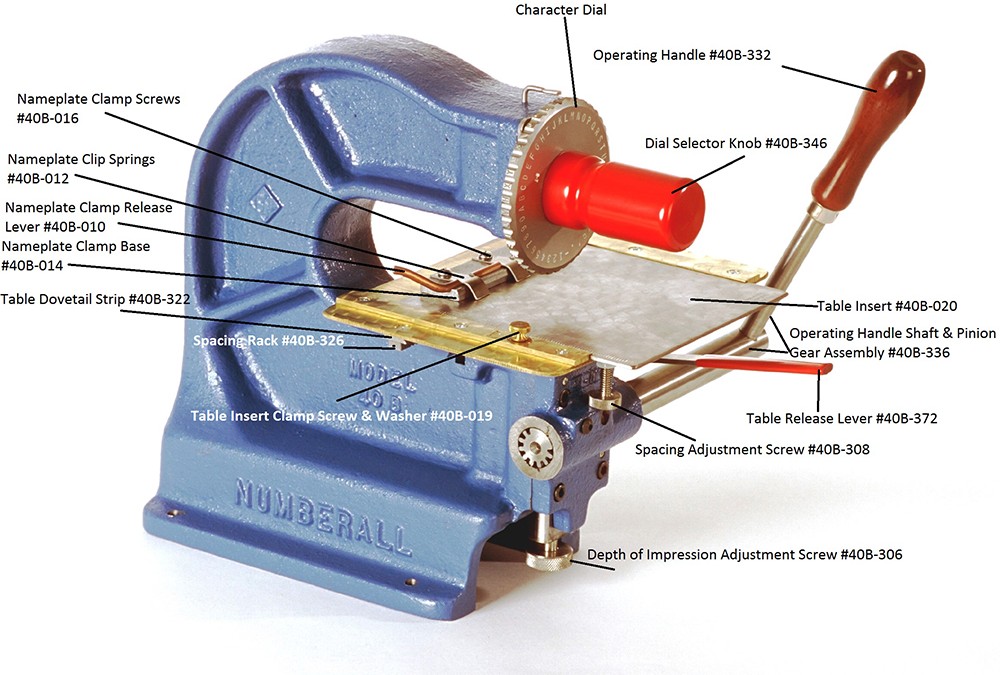

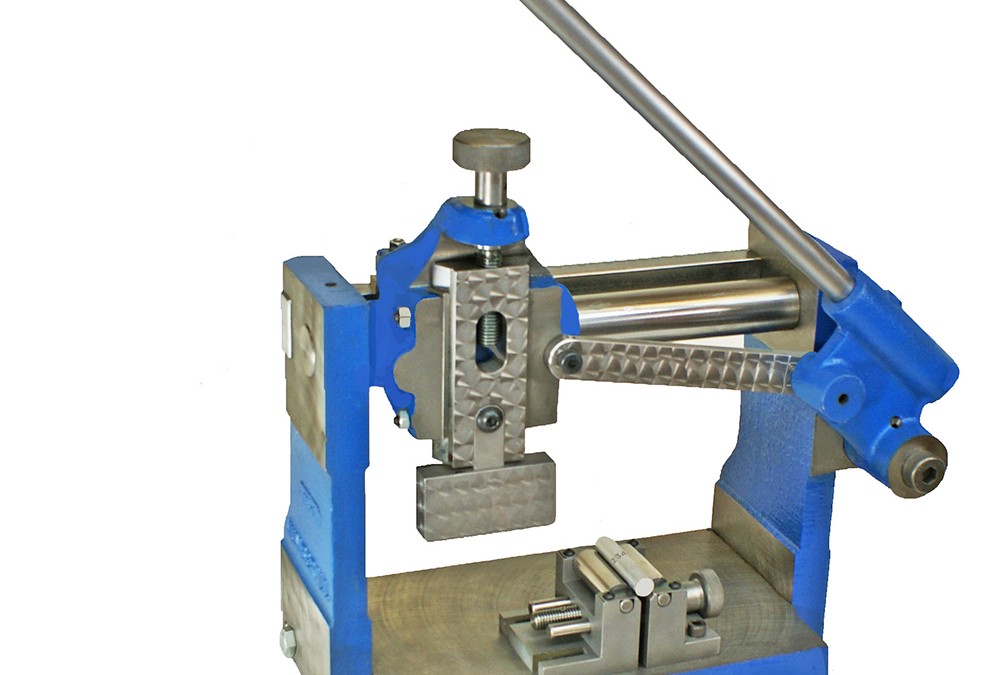

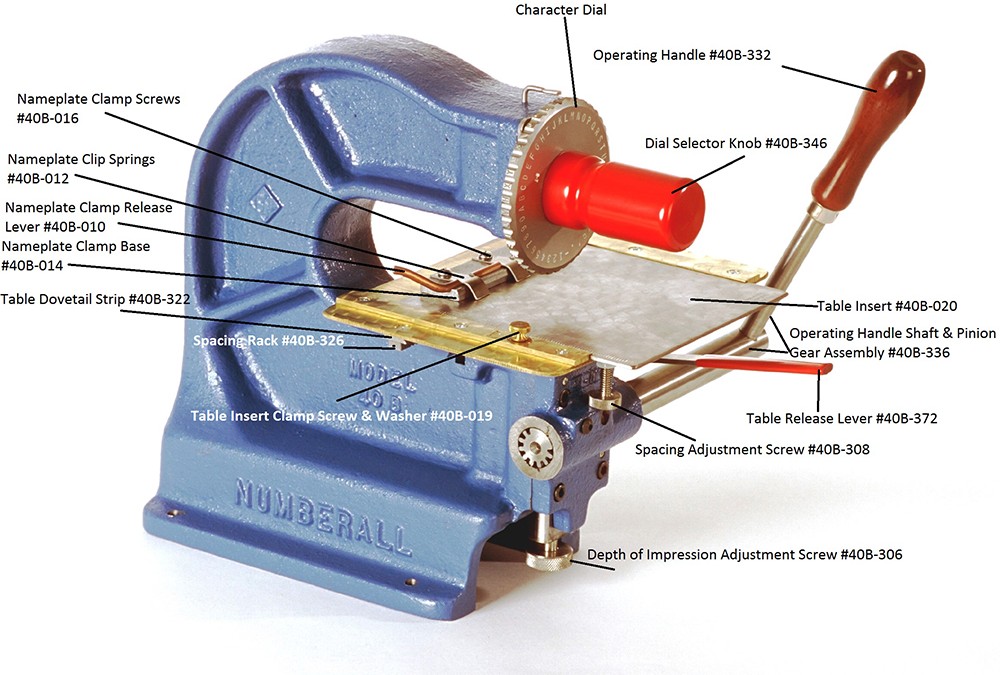

How to Space Text Using Model 40B Tutorial: How to Adjust the Model 40B’s Spacing Rack for Precision Stamping Since 1930, Numberall Stamp & Tool Co., a fourth-generation family business, has led the metal indent stamping industry, providing cost-effective,...

by Editor | Jun 15, 2016 | Blog

No matter what shape or size the item you want to mark is, Numberall Stamp and Tool Company has a machine for you. Flat pieces are the most common items that are stamped but we also have equipment to stamp round parts. Our Model 301 is the most economical solution for...

by Editor | Jun 1, 2016 | Blog

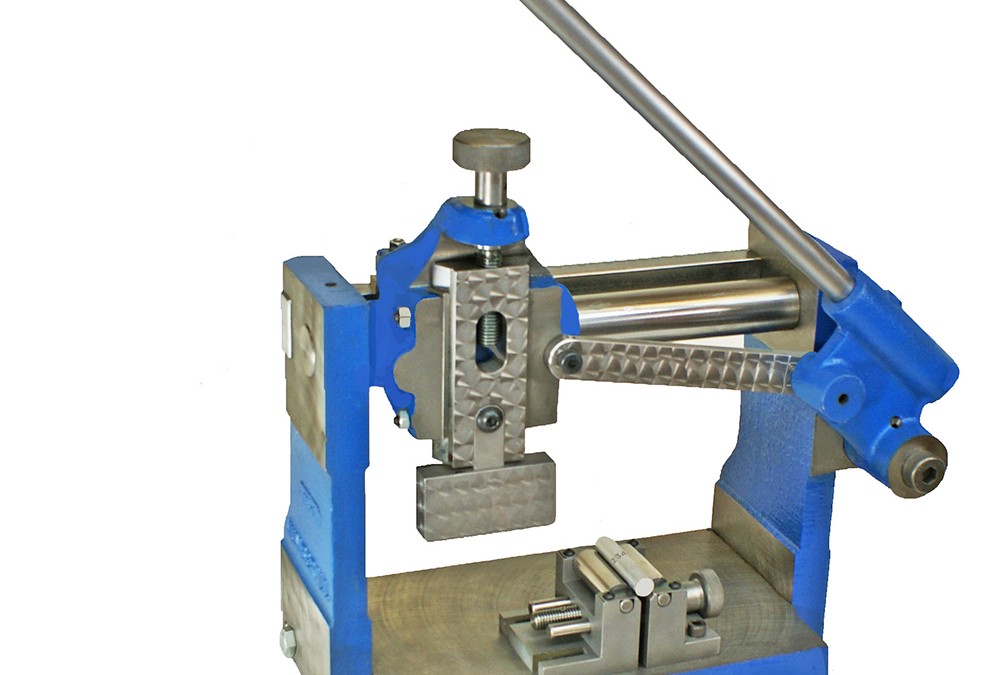

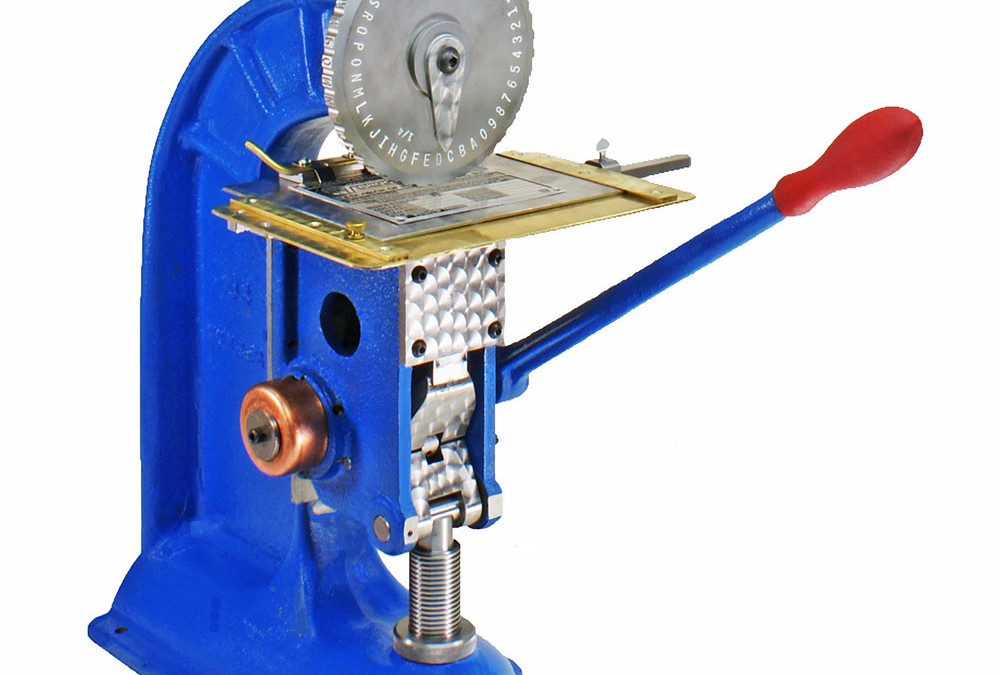

Numberall Stamp and Tool Company designs metal marking equipment that is easy to use, and tough enough to handle any task you use it for. Our Model 94 Press is a prime example of these qualities. This press is best suited for stamping codes in which each part requires...

by Numberall | May 18, 2016 | Blog

Numberall Stamp and Tool Company’s history has spanned over 85 years. During this time, we’ve been recognized for our products’ quality and value, including by several industry publications. In the 1930s, our secretary, H.Q. Bates, wrote about the use of our products...

by Numberall | May 4, 2016 | Blog

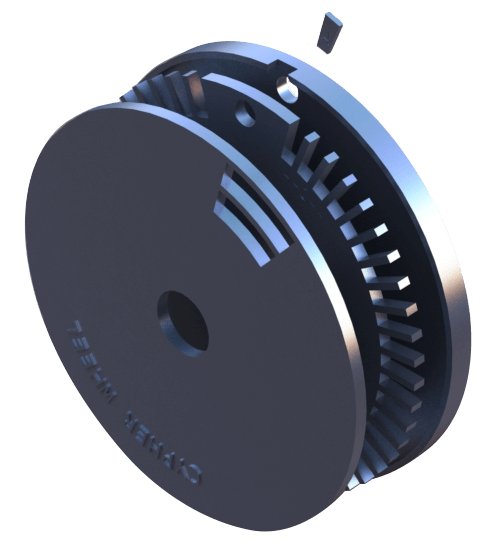

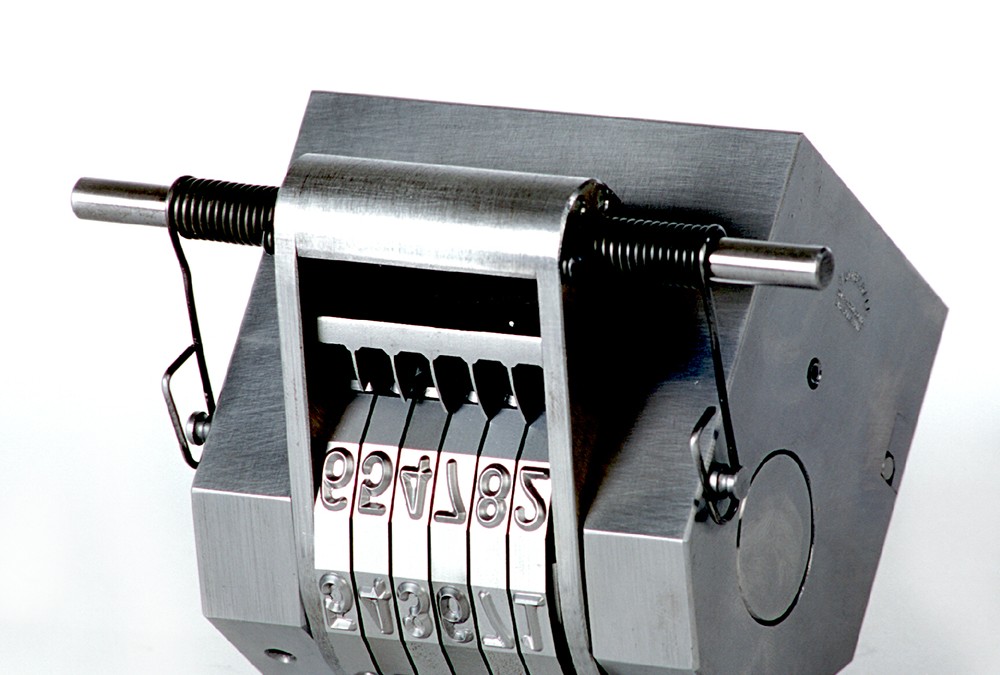

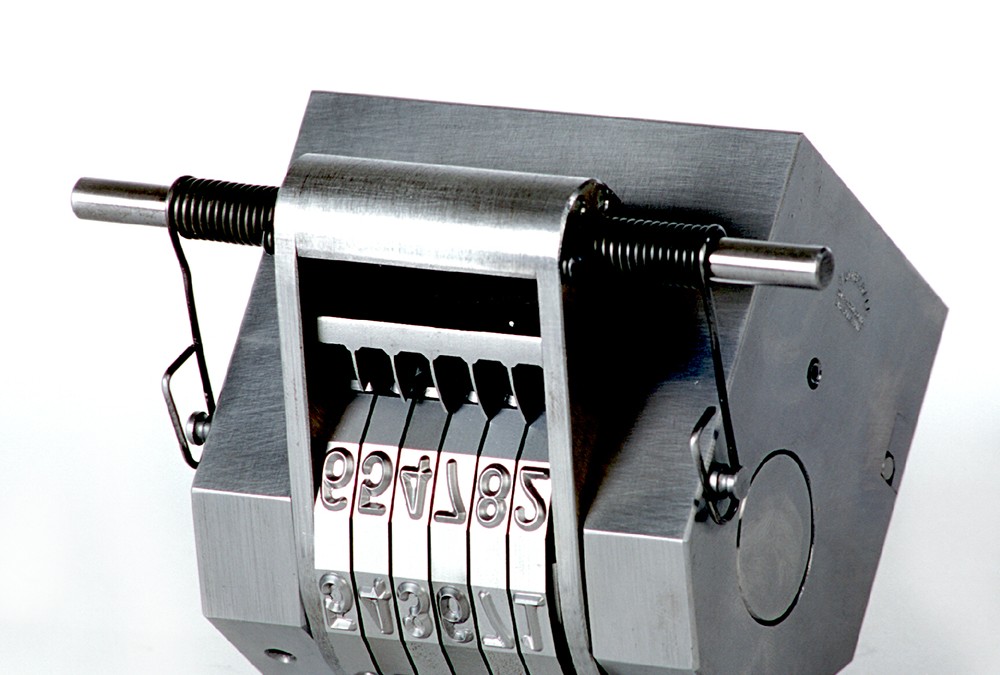

At Numberall Stamp and Tool Company we offer a variety of products to meet your marking needs. Our numbering heads are a prime example as they are used to directly mark on the item you are stamping. We offer three models of these products known as our Model 80P, 83P,...

by Numberall | Apr 19, 2016 | Blog

To keep your Numberall product in good working order, regular maintenance must be done. For wear items and consumables, it is almost always more cost effective to buy the parts and do the repairs. The Model 40B is an excellent, cost-effective machine to do this with...

by Numberall | Apr 5, 2016 | Blog

Numberall is known for products that last for decades. To make sure your machine lasts a long time, regular maintenance must be done. It is almost always more cost effective to perform regular maintenance than repair a damaged machine. The Model 50P is a machine that...

by Editor | Mar 31, 2016 | Blog

At Numberall, we stand behind our products. It’s inevitable that our products will become worn from regular use and need maintenance. We gladly service all of the products we sell, including discontinued items like the Model 48. Even if you’ve had your machine for a...